HKS 2-M Tricot Machine with 2 Bars

GrandStar HKS2 High-Speed Tricot Warp Knitting Machine

Adaptable, High-Efficiency Production for Coarse-Gauge and Low-Density Fabrics.

The GrandStar HKS2 is developed as a multifunctional tricot warp knitting solution tailored for producers seeking high-speed performance, extensive gauge adaptability, and consistent results at low stitch counts. Designed to meet the demands of the expanding elastic fabric markets, the HKS2 incorporates precise yarn management, cutting-edge spandex feeding technology, and GrandStar’s sturdy mechanical construction to produce top-quality fabrics across a diverse range of products.

1. Broad Production Flexibility for Diverse Applications

The HKS2 excels in a wide range of product categories, making it an ideal choice for manufacturers targeting:

- Stretch sportswear (yoga, fitness, running)

- Outdoor functional fabrics

- Swimwear and beachwear

- Intimate wear and body-shaping textiles

- Lightweight elastic fabrics for apparel and industrial use

Its flexible configuration supports seamless transitions between different yarn combinations, including polyester, nylon, and spandex blends.

2. Wide Gauge Selection for Coarse to Fine Elastic Fabrics

Available gauge range: E18 – E36

- E18–E24: Ideal for coarse-gauge structures and low stitch density fabrics

- E28–E32: Versatile for standard elastic fabrics

- E36: Supports ultra-tight stitch lengths for high-density, precision elastic textiles

This wide gauge coverage enables manufacturers to expand product portfolios using a single machine platform.

3. Precision Spandex Control with Closed-Loop Servo Technology

A key competitive strength of the HKS2 is its servo-driven, closed-loop spandex warp feed system, providing:

- Real-time tension feedback and correction

- High-accuracy spandex delivery

- Superior fabric uniformity and elasticity balance

- Reduced defects and improved repeatability in mass production

This advanced feeding technology ensures flawless synchronization with ground yarns, a critical factor for premium elastic fabrics.

4. Superior Operating Speed for Maximum Productivity

The GrandStar HKS2 operates at speeds of up to 3,800 rpm, making it one of the fastest tricot warp knitting machines in its class worldwide.

- Higher daily production output

- Stable performance at high operating speeds

- Reduced vibration through optimized mechanical architecture

- Long machine lifespan and lower total cost of ownership

5. Human-Centered Design for Enhanced Usability

The HKS2 incorporates ergonomic, user-friendly mechanical design, featuring:

- Clear and efficient operator access points

- Streamlined yarn path and threading design

- Modular components for faster maintenance

- Intuitive interface for quick machine adjustments

6. Competitive Advantages Over Industry Alternatives

Compared with machines in the same segment, the HKS2 delivers measurable advantages:

- Higher speed & productivity: Up to 3,800 rpm, outperforming many competing models.

- Superior spandex precision: Servo closed-loop control surpasses traditional mechanical systems.

- Wider gauge coverage: E18–E36 supports broader market demands with one machine.

- Elastic-fabric optimization: Yarn path and loop formation designed specifically for spandex-rich constructions.

7. The Fastest Tricot Machine in the GrandStar Collection

The HKS2 claims the leading position in the GrandStar series, boasting the highest operating speed and the longest needle stroke, specifically engineered to meet the demands of modern elastic fabric production. .

The GrandStar HKS2 Tricot Warp Knitting Machine is a durable, versatile, and innovative option for textile mills around the globe aiming to enhance their production efficiency, fabric quality, and competitive advantage. With its impressive speed, advanced spandex control, and adaptable gauge options, the HKS2 is an exceptional choice for manufacturers of high-performance elastic fabrics.

GrandStar® Warp Knitting Machine Specifications

Working Width Options:

- 4724mm (186″)

- 7366mm (290″)

- 8128mm (320″)

- 8636mm (340″)

- 9296mm (366″)

- 10058mm (396″)

Gauge Options:

- E28 and E32

Knitting Elements:

- Needle Bar: 1 individual needle bar utilizing compound needles.

- Slider Bar: 1 slider bar with plate slider units (1/2″).

- Sinker Bar: 1 sinker bar featuring compound sinker units.

- Guide Bars: 2 guide bars with precision-engineered guide units.

- Material: Carbon-fiber-reinforced composite bars for superior strength and reduced vibration.

Warp Beam Support Configuration:

- Standard: 2 × 812mm (32″) (free-standing)

- Optional:

- 2 × 1016mm (40″) (free-standing)

- 1 × 1016mm (40″) + 1 × 812mm (32″) (free-standing)

GrandStar® Control System:

The GrandStar COMMAND SYSTEM provides an intuitive operator interface, allowing seamless machine configuration and precise electronic function control.

Integrated Monitoring Systems:

- Integrated Laserstop: Advanced real-time monitoring system.

- Integrated Camera System: Provides real-time visual feedback for accuracy.

Yarn Let-Off System:

Each warp beam position features an electronically controlled yarn let-off drive for precise tension regulation.

Fabric Take-Up Mechanism:

Equipped with an electronically regulated fabric take-up system driven by a high-precision geared motor.

Batching Device:

A separate floor-standing cloth rolling device ensures smooth fabric batching.

Pattern Drive System:

- Standard: N-drive with three pattern discs and integrated tempi change gear.

- Optional: EL-drive with electronically controlled motors, allowing guide bars to shog up to 50mm (optional extension to 80mm).

Electrical Specifications:

- Drive System: Speed-regulated drive with a total connected load of 25 kVA.

- Voltage: 380V ± 10%, three-phase power supply.

- Main Power Cord: Minimum 4mm² three-phase four-core cable, ground wire no less than 6mm².

Oil Supply System:

Advanced oil/water heat exchanger ensures optimal performance.

Operating Environment:

- Temperature: 25°C ± 6°C

- Humidity: 65% ± 10%

- Floor Pressure: 2000-4000 kg/m²

Knitting Speed Performance:

Achieves exceptional knitting speeds of 2000 to 2600 RPM for high productivity.

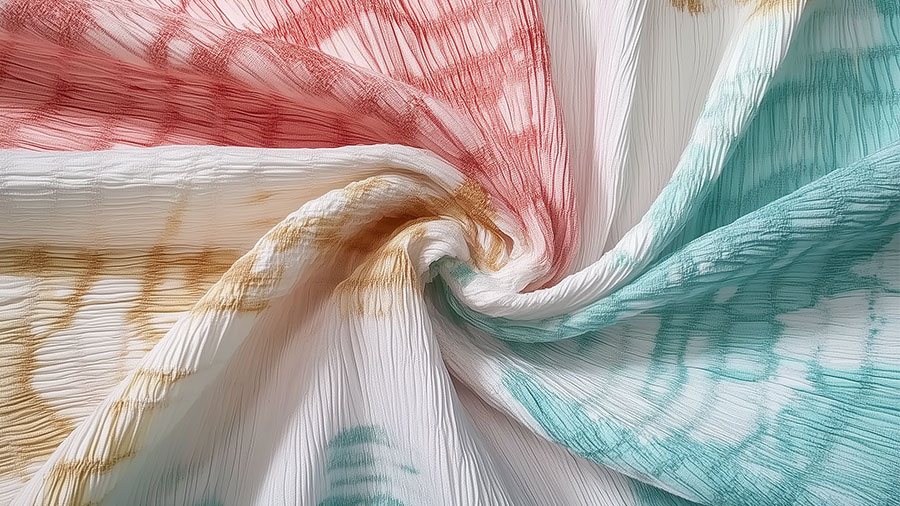

Warp knitting combined with crinkling techniques creates warp knitting crinkle fabric. This fabric features a stretchy, textured surface with a subtle crinkled effect, achieved through an extended needle bar movement with EL. Its elasticity varies based on yarn selection and knitting methods.

Equipped with the EL system, GrandStar warp knitting machines can produce athletic mesh fabrics with varying specifications and structures, tailored to different yarn and pattern requirements. These mesh fabrics enhance breathability, making them ideal for sportswear.

Our warp knitting machines produce high-quality velvet/tricot fabrics with unique pile effects. The pile is created by the front bar (bar II), while the rear bar (bar I) forms a dense, stable knitted base. The fabric structure combines a plain and counter notation tricot construction, with ground guide bars ensuring precise yarn positioning for optimal texture and durability.

Warp knitting machines from GrandStar enable the production of high-performance automotive interior fabrics. These fabrics are crafted using a specialized four-comb braiding technique on Tricot machines, ensuring durability and flexibility. The unique warp knitting structure prevents wrinkling when bonded with interior panels. Ideal for ceilings, skylight panels, and trunk covers.

Tricot warp knitted shoe fabrics offer durability, elasticity, and breathability, ensuring a snug yet comfortable fit. Engineered for athletic and casual footwear, they resist wear and tear while maintaining a lightweight feel for enhanced comfort.

Warp-knitted fabrics offer exceptional stretch and recovery, ensuring flexibility and freedom of movement for yoga practice. They are highly breathable and moisture-wicking, keeping the body cool and dry during intense sessions. With superior durability, these fabrics withstand frequent stretching, bending, and washing. Seamless construction enhances comfort, minimizing friction.

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CE EMC |

CE LVD |

CE MD |

UL |

ISO 9001 |

ISO 14001 |

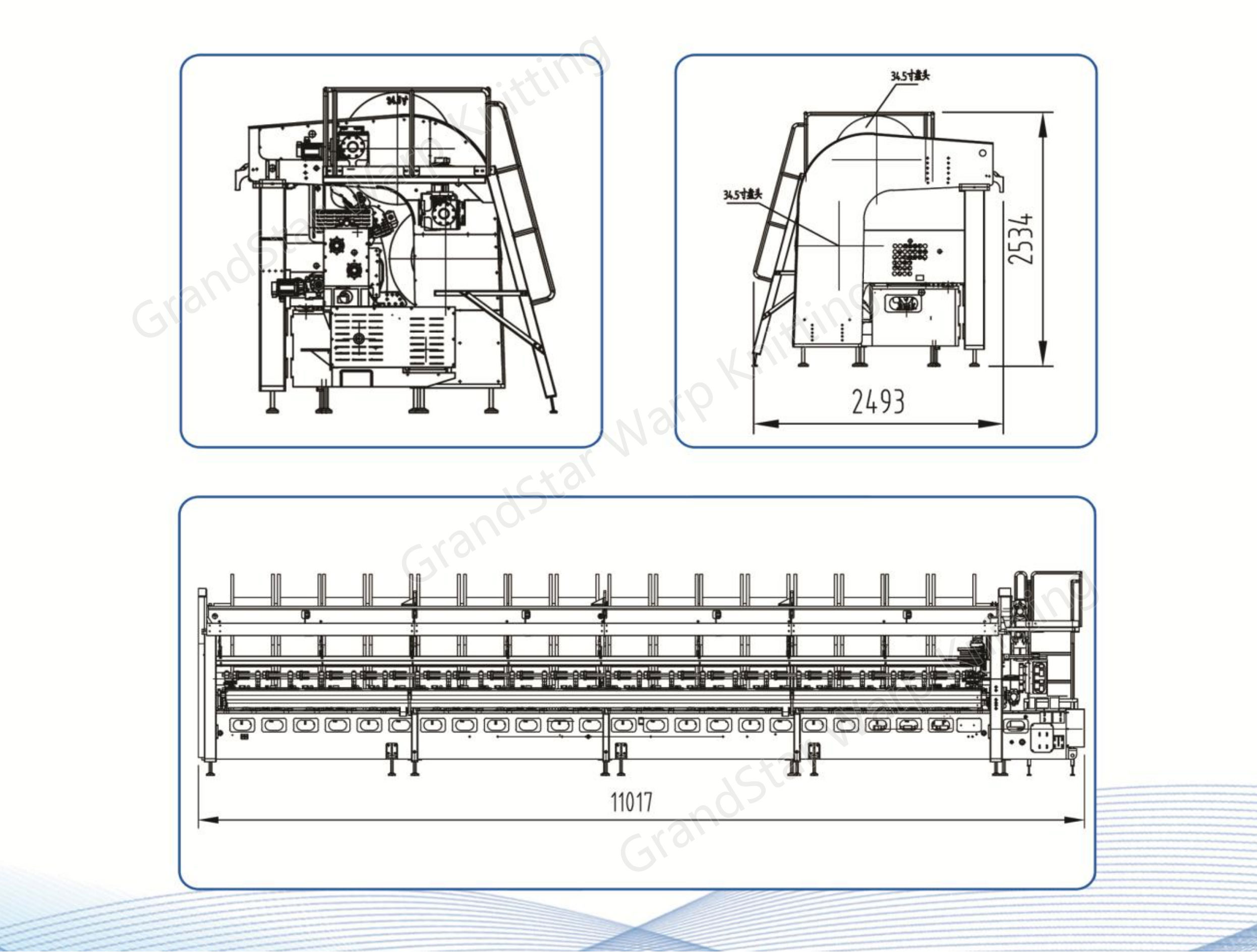

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

CONTACT US

CONTACT US