Fall Plate Raschel Jacquard Lace Machine TL91/1/36B

Multibar Jacquard Fall Plate Raschel Lace Machine

Advanced Solution for High-End Elastic and Rigid Lace Production

The Multibar Jacquard Fall Plate Raschel Lace Machine is engineered for manufacturers seeking precision, versatility, and artistic freedom in lace production. Designed for both elastic and rigid lace fabrics, this model enables the creation of three-dimensional patterned lace trims and all-over fabrics with intricate mesh structures and fine surface effects.

Unparalleled Fabric Creativity

Through advanced multibar jacquard and fall plate technology, the machine produces an extensive range of lace styles — from delicate lace galloons and trims to full-width rigid lace fabrics used in ladies’ outerwear, lingerie, and luxury fashion collections. The jacquard system delivers superior pattern accuracy and depth, making each fabric visually dynamic and structurally stable.

Precision-Driven Design & Flexible Configuration

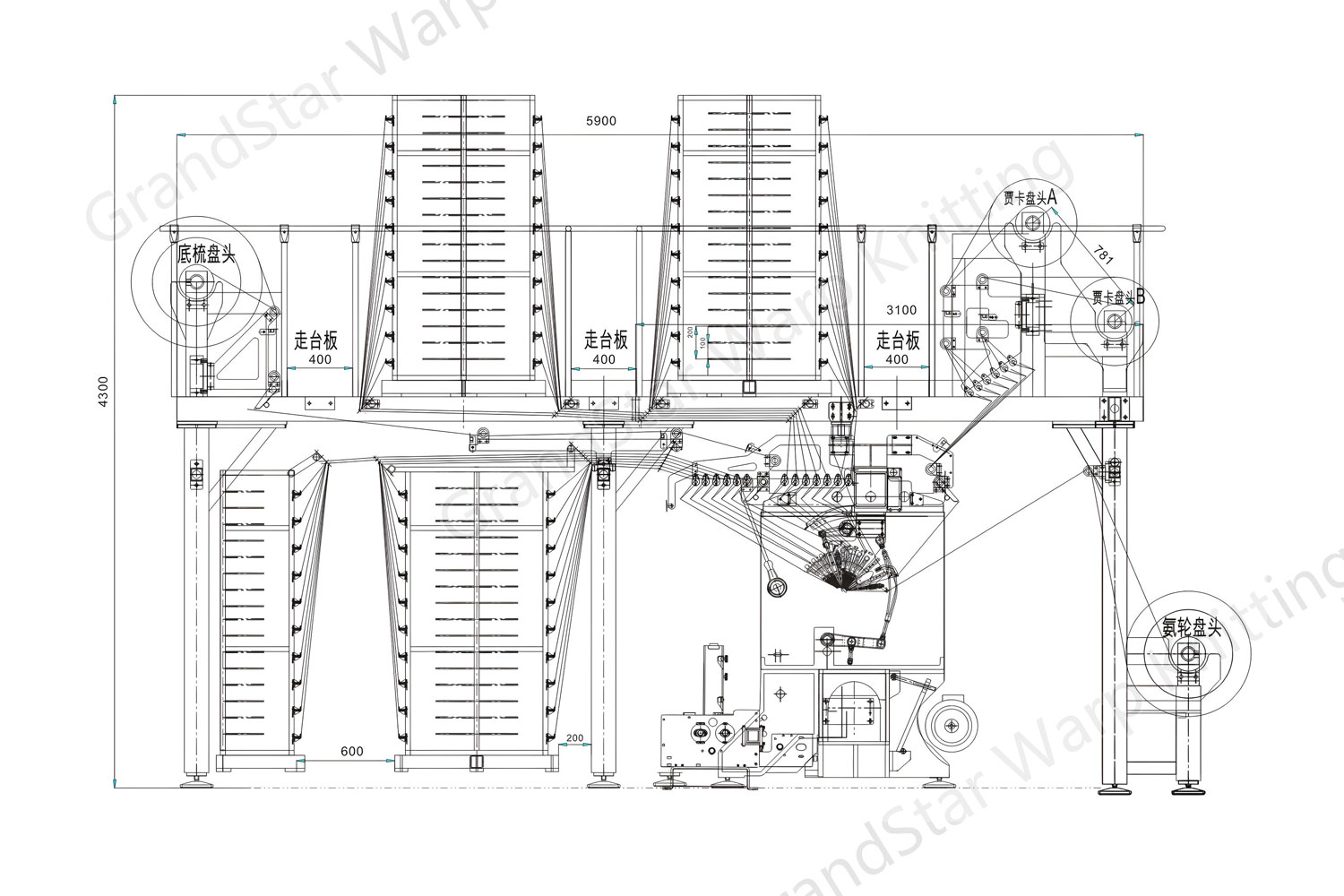

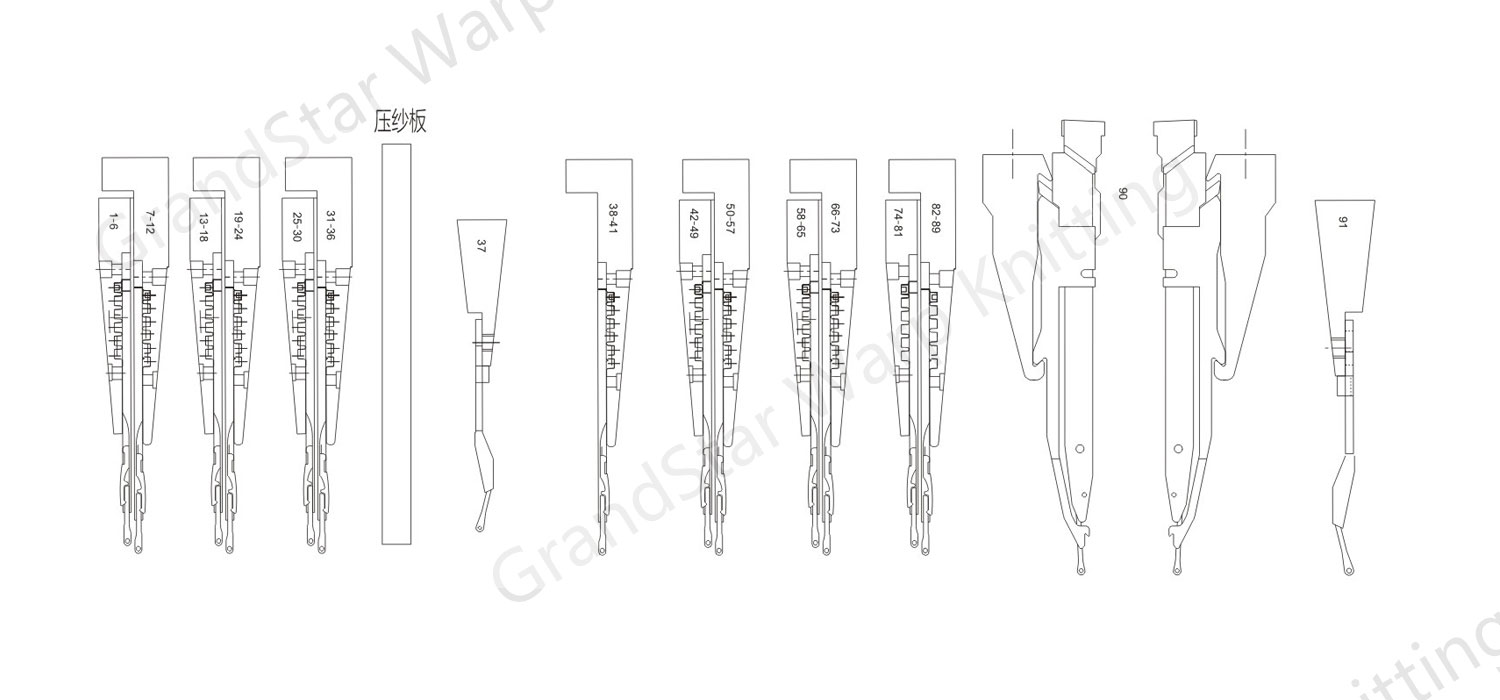

The series offers multiple configurations based on pattern bar quantity and jacquard bar positioning, allowing manufacturers to match exact production needs. Each configuration is optimized for stable high-speed operation, efficient yarn control, and fine tension management — ensuring consistent quality across large-scale production.

Distinct Advantages Over Conventional Lace Machines

- 3D Fabric Forming Precision – The unique fall plate structure enhances yarn layering for true depth and tactile texture.

- Superior Energy Efficiency – Optimized drive system reduces energy consumption by up to 30%, improving cost-effectiveness without compromising speed.

- Stable High-Speed Operation – Advanced cam and yarn guide systems ensure smooth motion control even at 2,000 rpm and above.

- Enhanced Patterning Capability – Each jacquard bar independently controls complex motifs, enabling precise replication of luxury lace designs demanded by global brands.

For the World’s Leading Fashion and Textile Innovators

Lace fabrics produced by this model consistently appear in international fashion shows, premium bridal collections, and intimate apparel lines of world-renowned brands. Combining technical mastery and artistic flexibility, the Multibar Jacquard Fall Plate Raschel Lace Machine is not only a production tool — it is a statement of excellence for manufacturers dedicated to premium quality and design innovation.

Technical Specifications – Premium Warp Knitting Machine Series

Working Widths

Available in 3 optimized configurations:

3403 mm (134″) ・ 5080 mm (200″) ・ 6807 mm (268″)

→ Designed to accommodate both standard and extra-wide fabric production with uncompromised precision.

Working Gauge

E18 ・ E24

→ Fine and medium-fine gauges for superior pattern definition across a wide range of textile applications.

Yarn Let-Off System

Triple electronically controlled yarn let-off gears for ground guide bars

→ Delivers constant yarn tension with adaptive feedback control for flawless loop formation and fabric uniformity.

Pattern Drive – EL Control

Advanced electronic guide bar control for both ground and string (pattern) guide bars

→ Enables intricate patterning and seamless repeat adjustments directly via digital interface.

Operator Console – GRANDSTAR COMMAND SYSTEM

Intelligent touchscreen control panel for machine configuration, diagnostics, and live parameter tuning

→ Empowers operators with intuitive access to every aspect of machine functionality, reducing setup time and boosting productivity.

Fabric Take-Up Unit

Electronically regulated system with geared motor and four rollers wrapped in anti-slip black grip tape

→ Ensures stable fabric advancement and consistent take-up tension, critical for quality in high-speed production.

Electrical System

Speed-regulated drive with a connected load of 25 kVA

→ Guarantees energy-efficient operation with high-torque performance, ideal for extended industrial use.

This seamless shapewear fabric is produced in a single panel, integrating lace patterns and shaping zones using stringbar technology and block multiguides with elastane. It features a built-in inner bra with a firm yet elastic zone, eliminating the need for underwire while enhancing support and comfort. The seamless process ensures a smooth fit, reduces production complexity, shortens lead time, and lowers manufacturing costs—making it ideal for efficient, high-quality shapewear applications in the apparel industry.

This lace fabric, uses a clipped pattern technique where threads are removed outside the design area to create isolated elements with an embroidered appearance. The method allows for extremely fine base structures, enhancing the visual contrast between the ground and the pattern. Finished with elegant eyelash edges along the motif, the result is a refined lace ideal for high-end fashion, lingerie, and bridalwear.

This elegant floral lace galloon is produced on a lace machine equipped with a front Jacquard bar, typically used for clip patterns. The standout feature lies in the use of an elastic Bourdon cord yarn as liners, enabling both refined texture and stretch. Ideal for high-end elastic lingerie, this configuration ensures design flexibility, structural integrity, and superior comfort.

This versatile fabric, produced on a high-output Jacquard lace machine, offers exceptional design flexibility for industrial applications. It supports two-way stretch for enhanced comfort, enables integration of brand logos and slogans, allows for the use of various yarn types, and can create striking 3D visual effects—all within one setup. While each feature can be used independently, they can also be combined for maximum impact.

This 2-way stretch lace offers excellent elastic recovery and a voluminous handle at 195g/m², making it both functional and comfortable. With integrated climate-regulating properties, it is well-suited for close-fitting outerwear in athleisure and activewear applications, providing flexibility, breathability, and a premium feel.

This Symm-Net lace pattern showcases a striking contrast between a fine, symmetrical ground and a bold edging yarn that defines the lace design. Finished with a refined eyelash border, it combines precision and texture for versatile use in high-end lingerie, fashion trims, and decorative applications.

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CONTACT US

CONTACT US