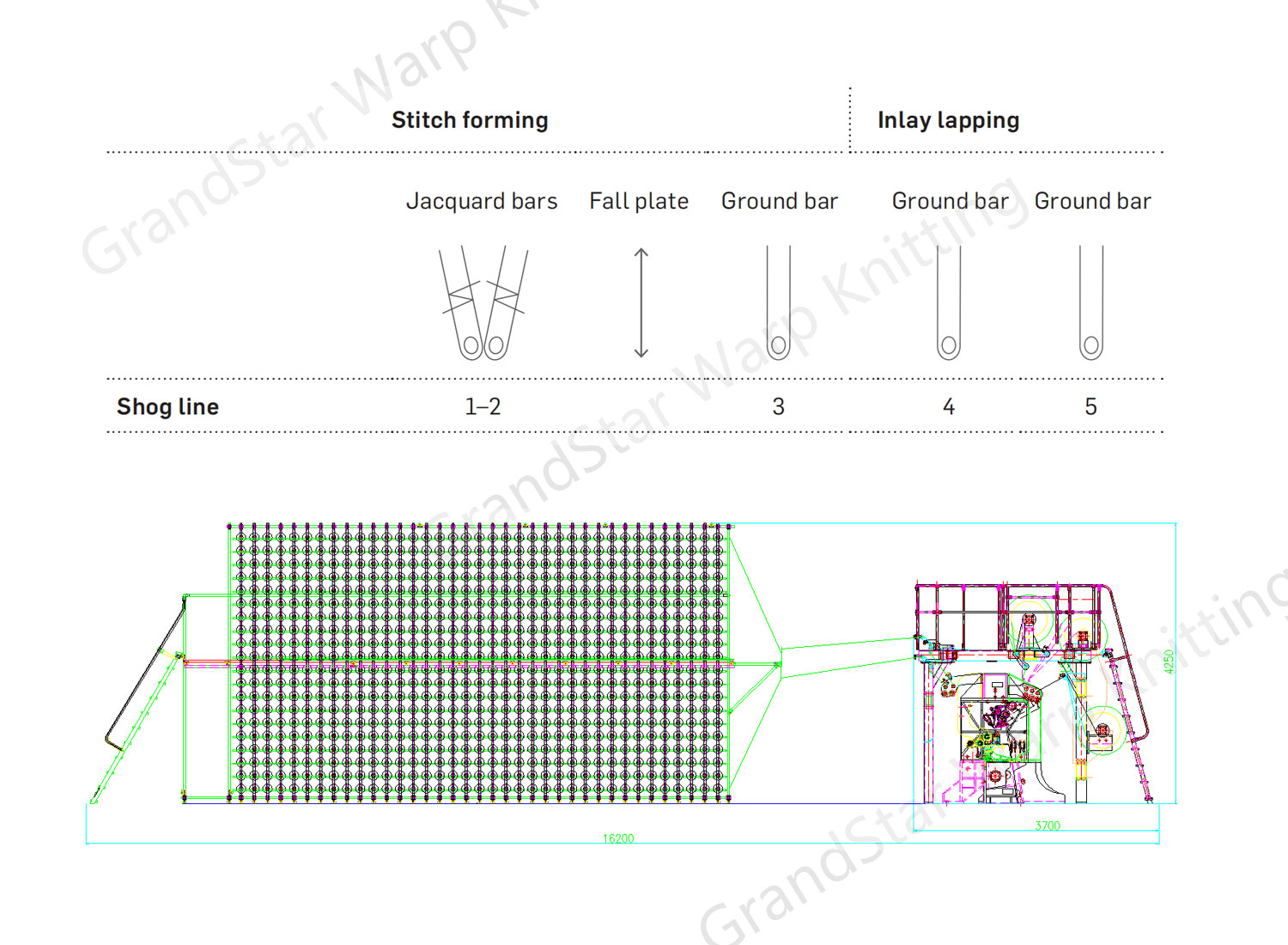

Curtain RJPC Jacquard Raschel Fallplate Warp Knitting Machine

Jacquard Raschel Machine with Fall Plate

Ultimate Pattern Flexibility for Net Curtains and Outerwear Production

Engineered for manufacturers seeking maximum design freedom and operational efficiency, our Jacquard Raschel Machine with Fall Plate redefines the production of decorative net curtains and high-performance outerwear fabrics. By integrating cutting-edge electronic control with proven mechanical stability, this model delivers unmatched patterning flexibility and industrial-grade reliability—ideal for customers operating in fast-evolving textile markets.

Key Advantages

1. Precision Patterning with EL Technology

Equipped with a state-of-the-art electronic guide bar control (EL system), this machine enables fully digital pattern adjustment with extreme accuracy. Whether you’re creating intricate floral lace for curtains or bold geometric designs for fashion outerwear, every stitch is executed with sharp definition—without mechanical modifications.

2. Seamless Pattern Changes, Maximum Uptime

Traditional Jacquard machines require manual intervention for pattern swaps, often leading to long downtimes. Our EL-controlled system eliminates this bottleneck, allowing rapid pattern changes via software updates, drastically reducing transition time and boosting machine availability.

3. High-Speed Production with Uncompromised Quality

This machine combines high-speed knitting capability with robust structural design, ensuring stable, uninterrupted operation even under intensive production schedules. Manufacturers benefit from consistent output quality across extended runs—critical for large-volume contracts.

4. Ergonomic Operation and Reduced Setup Time

Operators no longer need to perform time-consuming mechanical adjustments. The fall plate technology, paired with an intuitive control interface, significantly simplifies machine handling, reduces training requirements, and accelerates start-up after pattern updates or maintenance.

Why Choose This Machine Over Conventional Models?

Unlike traditional Raschel machines that limit design freedom and require mechanical effort to reconfigure patterns, our solution empowers manufacturers to respond faster to market trends, reduce changeover costs, and produce premium textile structures at industrial scale—all with a single platform.

This Jacquard Raschel machine is not just a technical upgrade—it’s a strategic asset for producers aiming to lead in the decorative textile and functional outerwear sectors.

Invest in the flexibility, speed, and precision that modern markets demand.

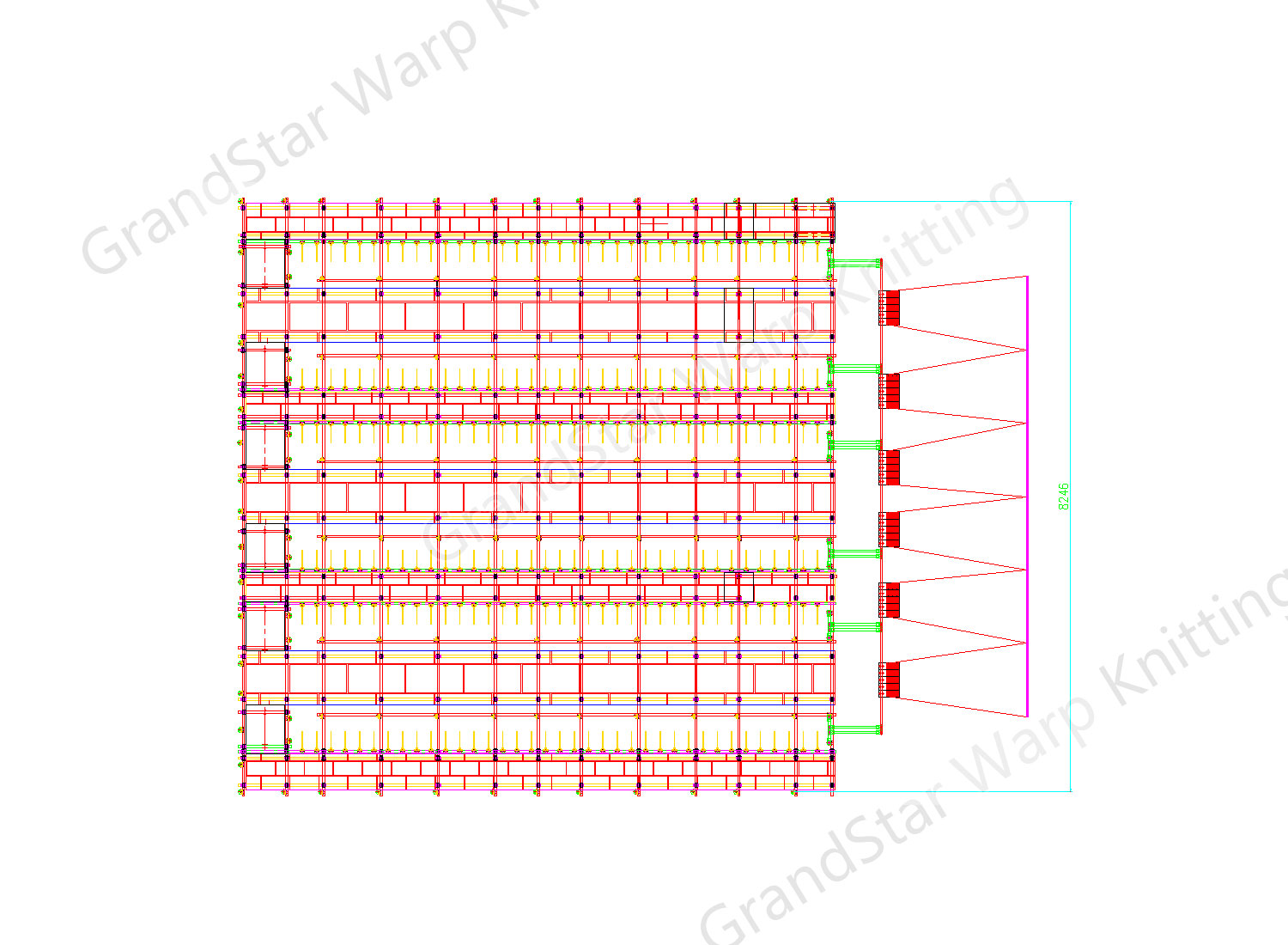

Working Width

Available in 3403 mm (134″), 5029 mm (198″), and 6146 mm (242″) to accommodate diverse fabric formats with uncompromised structural integrity.

Working Gauge

Precision-engineered gauges: E7, E12, E14, E18, and E24—ensuring optimal stitch definition for various yarn types and textile applications.

Yarn Let-Off System

Equipped with three electronically controlled let-off units for ground bars. Multi-speed operation ensures consistent tension for complex fabric constructions.

Pattern Control (EL System)

Advanced electronic guide bar control across all ground and Jacquard bars—enabling intricate, high-speed patterning with exceptional repeat accuracy.

GrandStar® COMMAND SYSTEM

Intuitive operator interface for real-time configuration and adjustment of all electronic functions—enhancing workflow efficiency and machine responsiveness.

Fabric Take-Up System

Electronically synchronized take-up driven by a geared motor, utilizing four grip-taped rollers—delivering smooth fabric transport and uniform tension control.

Batching Device

Independent rolling unit supports up to Ø685 mm (27″) diameter, engineered for uninterrupted production and efficient roll changeover.

Electrical Configuration

Speed-controlled main drive with a total connected load of 7.5 kW. Compatible with 380V ±10% three-phase supply. Requires ≥4mm² 4-core power cable and ≥6mm² grounding.

Operating Environment

Optimal machine performance at 25°C ±3°C and 65% ±10% humidity. Floor bearing capacity: 2000–4000 kg/m²—ideal for high-stability installations.

Creel System

Custom-configurable creel systems available to match Jacquard yarn specifications—supporting flexible yarn delivery and seamless integration.

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CONTACT US

CONTACT US