Split Warping Machine For Filament

Split Warping Machine – Precision in Mother Yarn Processing

The Split Warping Machine, also known as the Mother Yarn Warping Machine, is engineered to divide mother yarn into uniform monofilament yarns. This process is critical for applications on double needle bar Raschel machines and Tricot machines, where yarn consistency directly determines fabric performance and production efficiency.

Direct Beam Warping Advantage

Unlike conventional methods that require dividing mother yarn into bobbins before warping, our Split Warping Machine allows direct conversion of mother yarns into beams. This streamlined process significantly reduces time, labor costs, and yarn handling steps, ensuring higher working efficiency and greater production stability.

By eliminating the bobbin intermediate step, the system not only enhances speed but also minimizes yarn damage and waste, enabling manufacturers to maximize yield while maintaining strict quality standards.

GrandStar Engineering Excellence

At GrandStar, every Split Warping Machine is built with high-quality mechanical components and state-of-the-art electronic systems to guarantee reliability, precision, and longevity. Each machine is delivered with a comprehensive installation and operation manual, allowing customers to achieve rapid start-up and smooth operation with minimal technical barriers.

Our design philosophy focuses on energy efficiency, intelligent control, and durability, positioning GrandStar machines ahead of comparable models from traditional competitors.

Key Features & Competitive Edge

- Multi-Beam Copying Precision – Mother beams can be replicated into multiple identical beams with exceptional accuracy, ensuring uniformity across entire production batches.

- Advanced Micro-Computer Monitoring – Real-time detection of beam diameters with automatic tension regulation guarantees equal diameters, outer perimeter, and lengths across all beams.

- Intelligent Tension Control – Dual pneumatic tension rollers, combined with PID-controlled regulation, deliver stable yarn tension. Special wear-resistant roller surfaces extend service life and ensure smooth yarn running.

- Flexible Parameter Adjustments – Warping parameters can be revised online. Operators may adjust mother beam lengths or sub-beam perimeters without halting production, reducing downtime.

- Pneumatic Beam Handling System – Beams are loaded and unloaded via pneumatic vertical lift, ensuring stable movement, precise positioning, and improved operator safety.

- Energy-Efficient Servo Control – The machine adopts asynchronous servo-driven technology, reducing energy consumption while maintaining precision.

- Fault Detection & Power-Failure Protection – Automatic error alarms with high calculation precision, plus a large-capacity backup battery, ensure safe shutdown during sudden power loss.

Why Choose GrandStar?

While other manufacturers offer basic splitting machines, GrandStar sets a higher benchmark by integrating intelligent automation, superior tension stability, and robust safety systems. Our machines deliver not only cost savings and efficiency gains but also long-term operational reliability, enabling textile producers to maintain a competitive edge in demanding global markets.

✅ Result: Greater efficiency, higher precision, reduced energy costs, and unmatched durability—backed by GrandStar’s world-class engineering expertise.

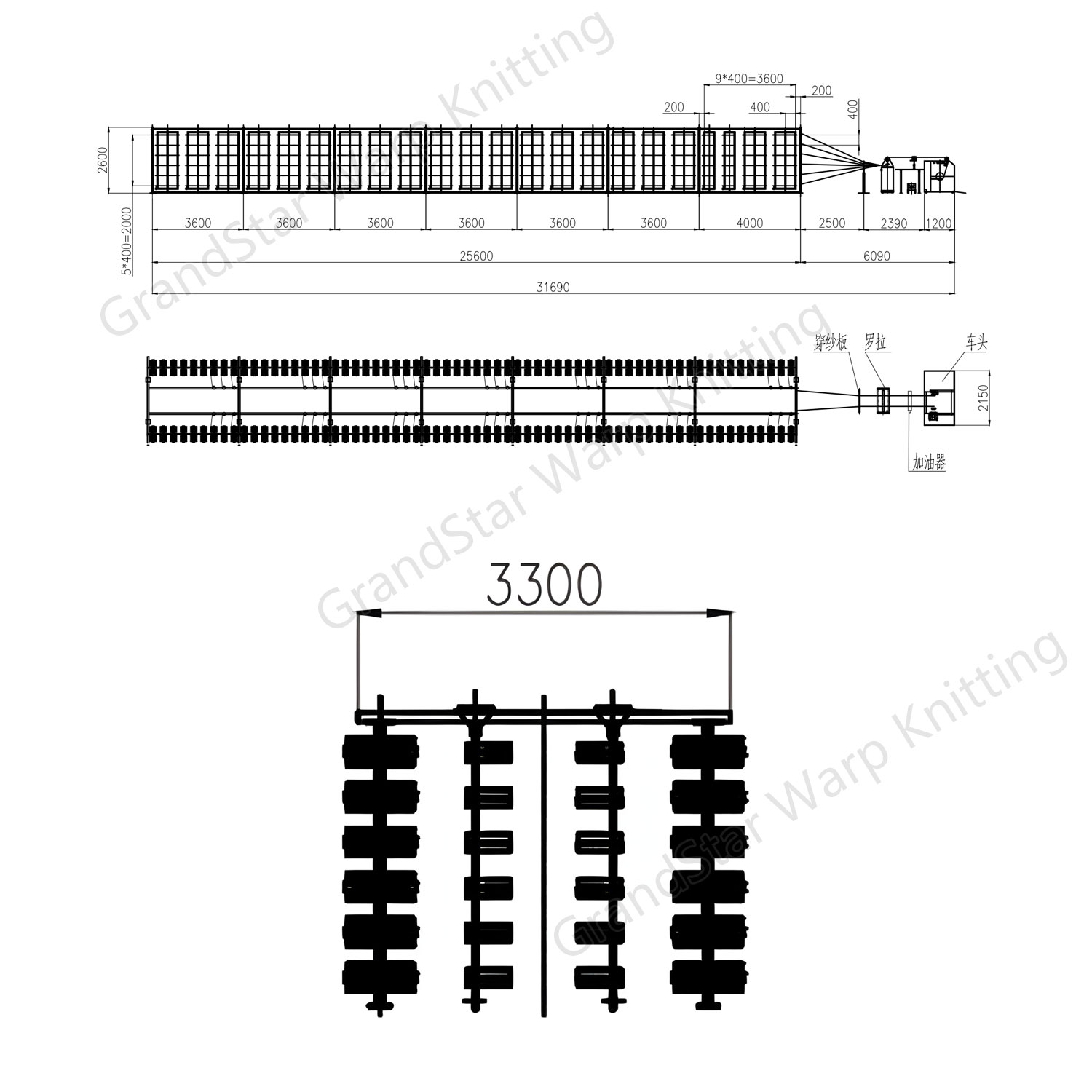

Direct Warping Machine – Technical Specifications

Our direct warping machine is engineered to deliver maximum efficiency, precision, and reliability for premium warp knitting operations. Every detail is designed to transform technical performance into tangible client value.

Key Technical Data

- Maximum Warping Speed: 1,200 m/min

Achieve superior productivity with industry-leading speed while maintaining consistent yarn quality. - Warp Beam Sizes: 21″ × (inch), 21″ × 30″ (inch), and customized sizes available

Flexibility to meet diverse production demands and client-specific requirements. - Computer Real-Time Control & Monitoring

Intelligent system ensures precise, continuous process oversight with optimized operator efficiency. - Tension Roller with PID Closed-Loop Adjustment

Real-time yarn tension control guarantees uniform winding quality and minimizes production defects. - Hydropneumatic Beam Handling System (Up/Down, Clamping, Brakes)

Robust automation delivers effortless operation, safe handling, and extended machine lifespan. - Direct Pressure Press Roll with Kick-Back Control

Provides stable yarn layering and prevents slippage, enhancing beam accuracy. - Main Motor: 7.5 kW AC Frequency-Controlled Drive

Maintains constant linear speed through closed-circuit regulation for smooth, energy-efficient operation. - Brake Torque: 1,600 Nm

Powerful braking system ensures rapid response and enhanced safety during high-speed runs. - Air Connection: 6 bar

Optimized pneumatic integration for reliable auxiliary functions and consistent machine performance. - Copy Precision: Error ≤ 5 m per 100,000 m

High-precision warping ensures exact fabric quality, minimizing waste and maximizing profitability. - Maximum Counting Range: 99,999 m (per cycle)

Extended measurement capability supports long-run operations without interruption.

Why Clients Choose This Machine

- Unmatched Productivity: High speed combined with precise control shortens lead times.

- Premium Quality Output: Closed-loop tension system ensures flawless fabric standards.

- Flexible Adaptability: Wide range of beam sizes and customization options.

- Operator-Friendly Design: Automated hydropneumatic handling reduces labor intensity.

- Proven Reliability: Engineered for long-term durability with elite safety standards.

This specification sheet reflects GrandStar’s commitment to setting the benchmark in warp knitting technology. Our direct warping machine empowers manufacturers to achieve faster production, higher quality, and stronger competitiveness in the global textile market.

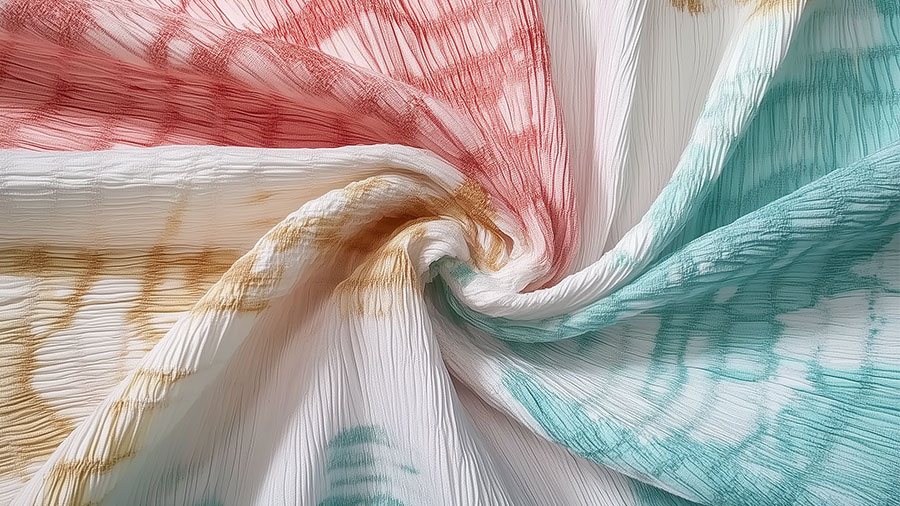

Warp knitting combined with crinkling techniques creates warp knitting crinkle fabric. This fabric features a stretchy, textured surface with a subtle crinkled effect, achieved through an extended needle bar movement with EL. Its elasticity varies based on yarn selection and knitting methods.

Equipped with the EL system, GrandStar warp knitting machines can produce athletic mesh fabrics with varying specifications and structures, tailored to different yarn and pattern requirements. These mesh fabrics enhance breathability, making them ideal for sportswear.

Our warp knitting machines produce high-quality velvet/tricot fabrics with unique pile effects. The pile is created by the front bar (bar II), while the rear bar (bar I) forms a dense, stable knitted base. The fabric structure combines a plain and counter notation tricot construction, with ground guide bars ensuring precise yarn positioning for optimal texture and durability.

Warp knitting machines from GrandStar enable the production of high-performance automotive interior fabrics. These fabrics are crafted using a specialized four-comb braiding technique on Tricot machines, ensuring durability and flexibility. The unique warp knitting structure prevents wrinkling when bonded with interior panels. Ideal for ceilings, skylight panels, and trunk covers.

Tricot warp knitted shoe fabrics offer durability, elasticity, and breathability, ensuring a snug yet comfortable fit. Engineered for athletic and casual footwear, they resist wear and tear while maintaining a lightweight feel for enhanced comfort.

Warp-knitted fabrics offer exceptional stretch and recovery, ensuring flexibility and freedom of movement for yoga practice. They are highly breathable and moisture-wicking, keeping the body cool and dry during intense sessions. With superior durability, these fabrics withstand frequent stretching, bending, and washing. Seamless construction enhances comfort, minimizing friction.

Main Warper |

Roller For Warper |

Creel For Warper |

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CONTACT US

CONTACT US