Slider Block For Warp Knitting Karl Mayer Raschel Machine

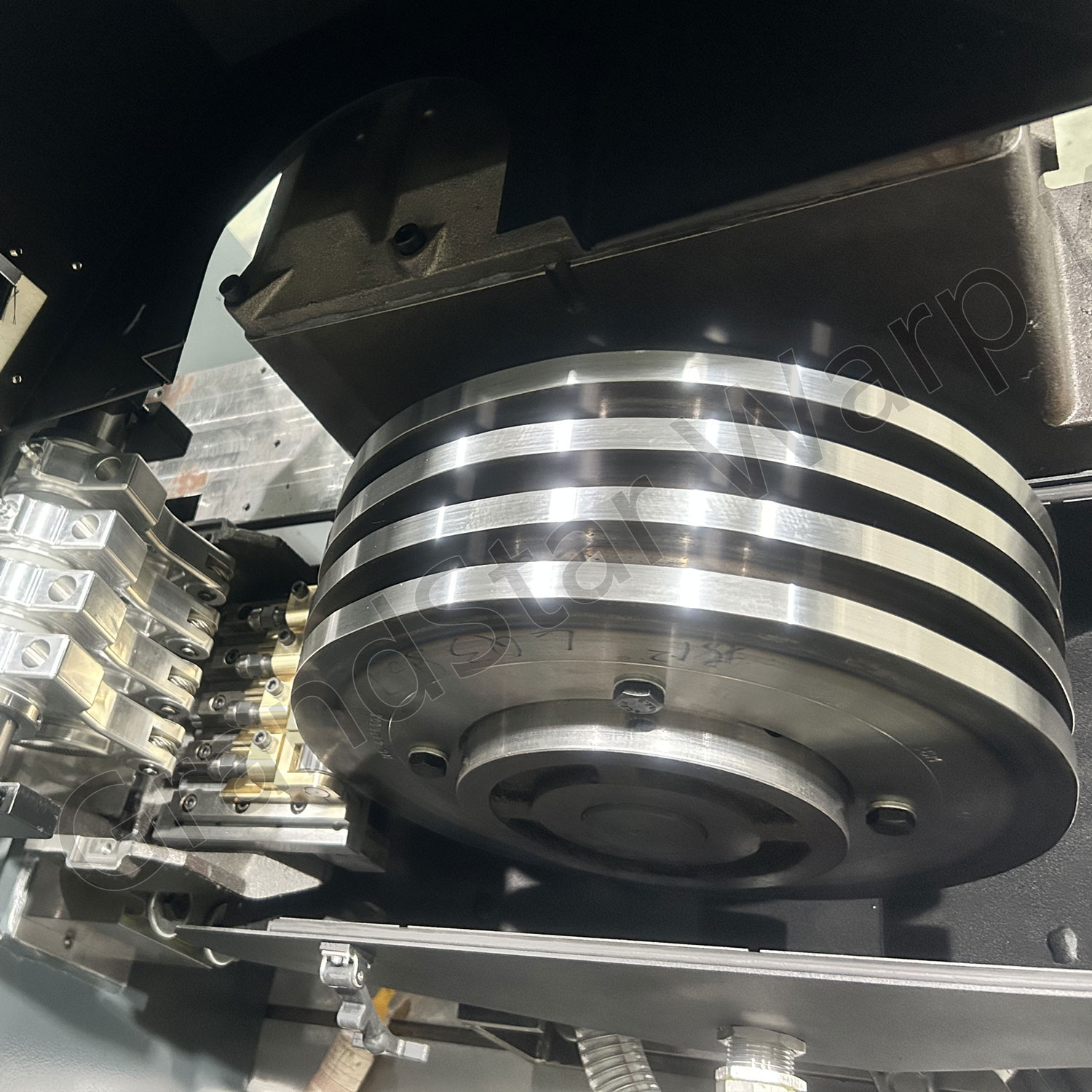

GrandStar Precision Sliders for High-Speed Warp Knitting Machines

GrandStar designs and manufactures next-generation sliders engineered for the most demanding warp knitting applications. Our slider technology is compatible with Tricot (HKS / KS / TM), Terry Towel, Raschel, Double Needle Bar, and LIBA systems—supporting both Karl Mayer and all major Chinese-brand machines.

Developed with advanced materials, ultra-tight tolerances, and long-life mechanical architecture, GrandStar sliders deliver exceptional stability at high speeds, ensuring consistent fabric quality and uninterrupted production for premium textile manufacturers worldwide.

Unmatched Engineering for High-Speed Performance

Each GrandStar slider functions as a precision motion component designed for continuous 24-hour operation. By combining a premium alloy body with hardened, high-torque screws, our sliders achieve:

- Zero-backlash movement for precise loop formation

- Over 1,000,000 cycles of durability under industrial workloads

- 99.9% uptime for smooth, uninterrupted production

- Rigid deformation resistance at 3,000 RPM

This level of mechanical reliability lets manufacturers run higher speeds with confidence, maximizing productivity without compromising fabric quality.

Key Technical Advantages

1. Premium Alloy Body

- High-strength, wear-resistant alloy with long-term dimensional stability

- Zero deformation at 3,000 RPM under heavy loading

- Low thermal expansion ensures accuracy during extended operation

2. Hardened High-Torque Screws

- Corrosion-proof surface treatment

- Up to 50% longer lifespan than standard screws used by typical Chinese OEMs

- Smooth sliding motion reduces vibration and noise

3. Universal Cross-Brand Compatibility

- Compatible with Karl Mayer, LIBA, and all Chinese machine brands

- Fits HKS / KS / TM, Double Needle Bar, Raschel, and Terry Towel machines

- Precision-matched geometry for plug-and-play installation

4. Customized Solutions for Specialty Fabrics

- High-pile terry towel fabrics

- High-speed Tricot lace and lingerie

- 3D mesh, blankets, sports footwear, seamless garments

- LIBA & Raschel plush, faux fur, and curtain textiles

Application Coverage

Tricot & Lace

Ensures stitch accuracy and clean loop formation at maximum RPM for lingerie, elastic fabrics, and curtain sheers.

Terry Towel Machines

Superior rigidity stabilizes pile height and loop density, ideal for microfiber cleaning cloths, kitchen towels, and car-wash fabrics.

Double Needle Bar Machines

Built to support heavy reversing loads for 3D mesh, blankets, shoe fabrics, and seamless garments.

Raschel & LIBA

Optimized for lace, faux fur, home textiles, and warp-knitted jacquards requiring precise motion transfer.

Why GrandStar Stands Above Competitors

- Higher precision with zero-backlash architecture

- Longer lifespan than typical domestic slider systems

- Universal cross-brand compatibility simplifies spare parts management

- Verified stability above 3,000 RPM, exceeding industry norms

For manufacturers seeking consistent quality, reduced downtime, and optimized productivity, GrandStar sliders provide a clear technical and economic advantage.

GrandStar – Precision That Drives the Future of Warp Knitting

Our commitment to engineering excellence ensures every slider delivers the reliability, speed,

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CE EMC |

CE LVD |

CE MD |

UL |

ISO 9001 |

ISO 14001 |

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

Technial Pattern |

CONTACT US

CONTACT US