RSE-4 (EL) Raschel Machine with 4 Bars

GrandStar RSE-4 High-Speed Elastic Raschel Machine

Redefining Efficiency, Versatility, and Precision in Modern Textile Manufacturing

Leading the Global Market with Next-Generation 4-Bar Raschel Technology

The GrandStar RSE-4 Elastic Raschel Machine represents a technological leap in warp knitting — designed to exceed the most demanding production requirements for elastic and non-elastic fabrics. Leveraging cutting-edge engineering and materials, the RSE-4 delivers unrivaled speed, durability, and adaptability, empowering manufacturers to stay ahead in competitive global markets.

Why the RSE-4 Sets the Global Standard

1. World’s Fastest and Widest 4-Bar Raschel Platform

The RSE-4 redefines productivity benchmarks with exceptional operational speed and market-leading working width. Its advanced configuration enables higher output volumes without compromising fabric quality — making it the most efficient 4-bar Raschel solution available worldwide.

2. Dual-Gauge Flexibility for Maximum Application Range

Engineered for ultimate versatility, the RSE-4 seamlessly transitions between fine and coarse gauge production. Whether crafting delicate elastic textiles or robust technical fabrics, this machine delivers consistent precision, stability, and superior fabric performance across all applications.

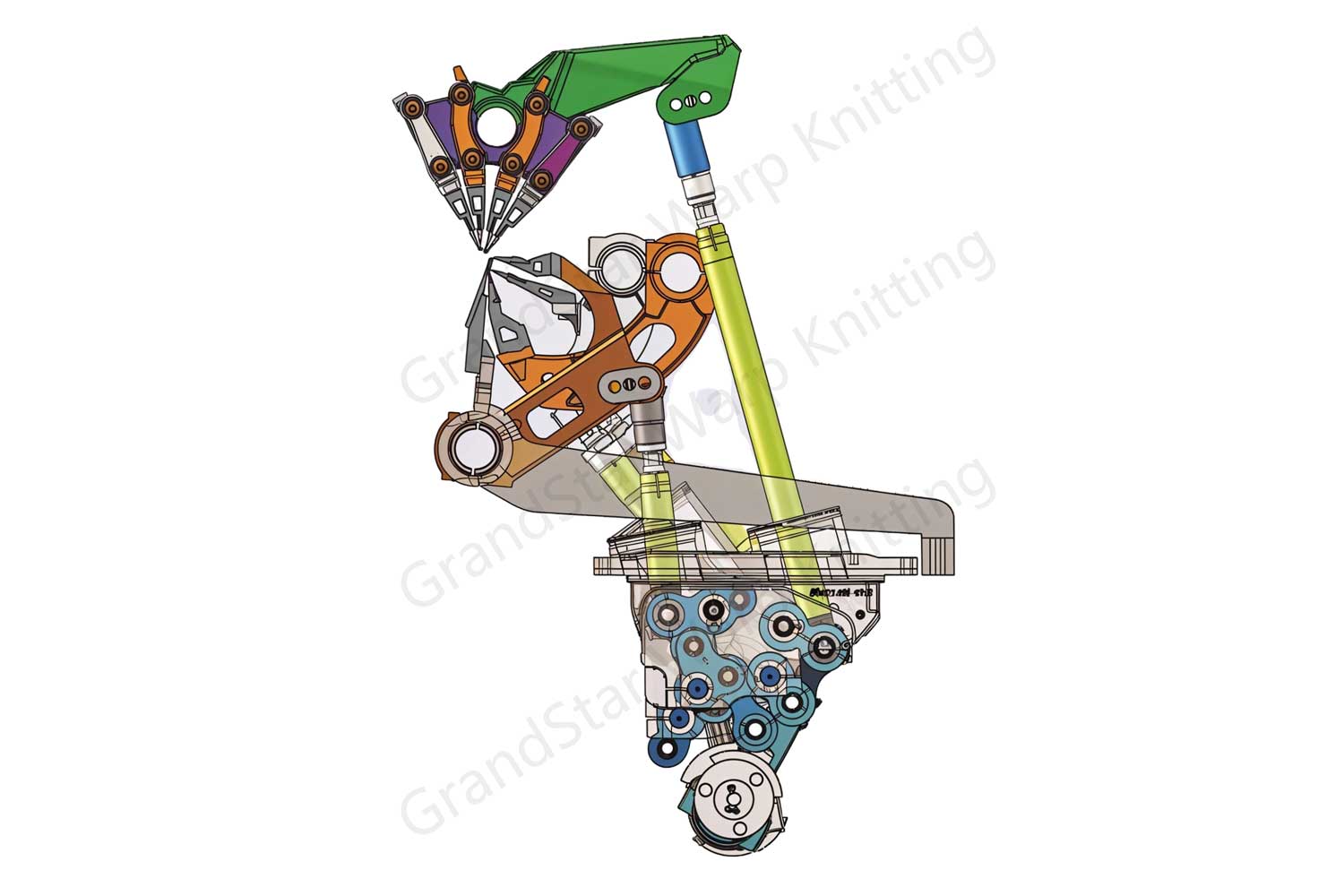

3. Reinforced Carbon Fiber Technology for Unmatched Structural Integrity

Every machine bar is constructed using carbon-fiber reinforced composites — a technology adopted from high-performance industries. This ensures minimized vibration, enhanced structural rigidity, and extended operational lifespan, resulting in smoother production at higher speeds with reduced maintenance requirements.

4. Productivity and Versatility — No Compromise

The RSE-4 eliminates the traditional trade-off between output and flexibility. Manufacturers can efficiently produce a broad spectrum of fabric styles — from intimate apparel and sports textiles to technical mesh and specialty Raschel fabrics — all on a single, high-efficiency platform.

GrandStar Competitive Advantages — Beyond the Ordinary

- Market-Leading Output Speeds with Uncompromised Quality

- Broader Working Width for Higher Throughput

- Advanced Material Engineering for Long-Term Reliability

- Flexible Gauge Options Tailored to Market Demands

- Engineered to Global Premium Standards

Future-Proof Your Production with GrandStar RSE-4

In a market where speed, adaptability, and reliability define success, the RSE-4 empowers textile producers to unlock new possibilities — delivering consistent, high-quality results with lower operational costs.

Choose GrandStar — Where Innovation Meets Industry Leadership.

GrandStar® High-Performance Raschel Machine — Engineered for Maximum Output & Flexibility

Technical Specifications

Working Width / Gauge

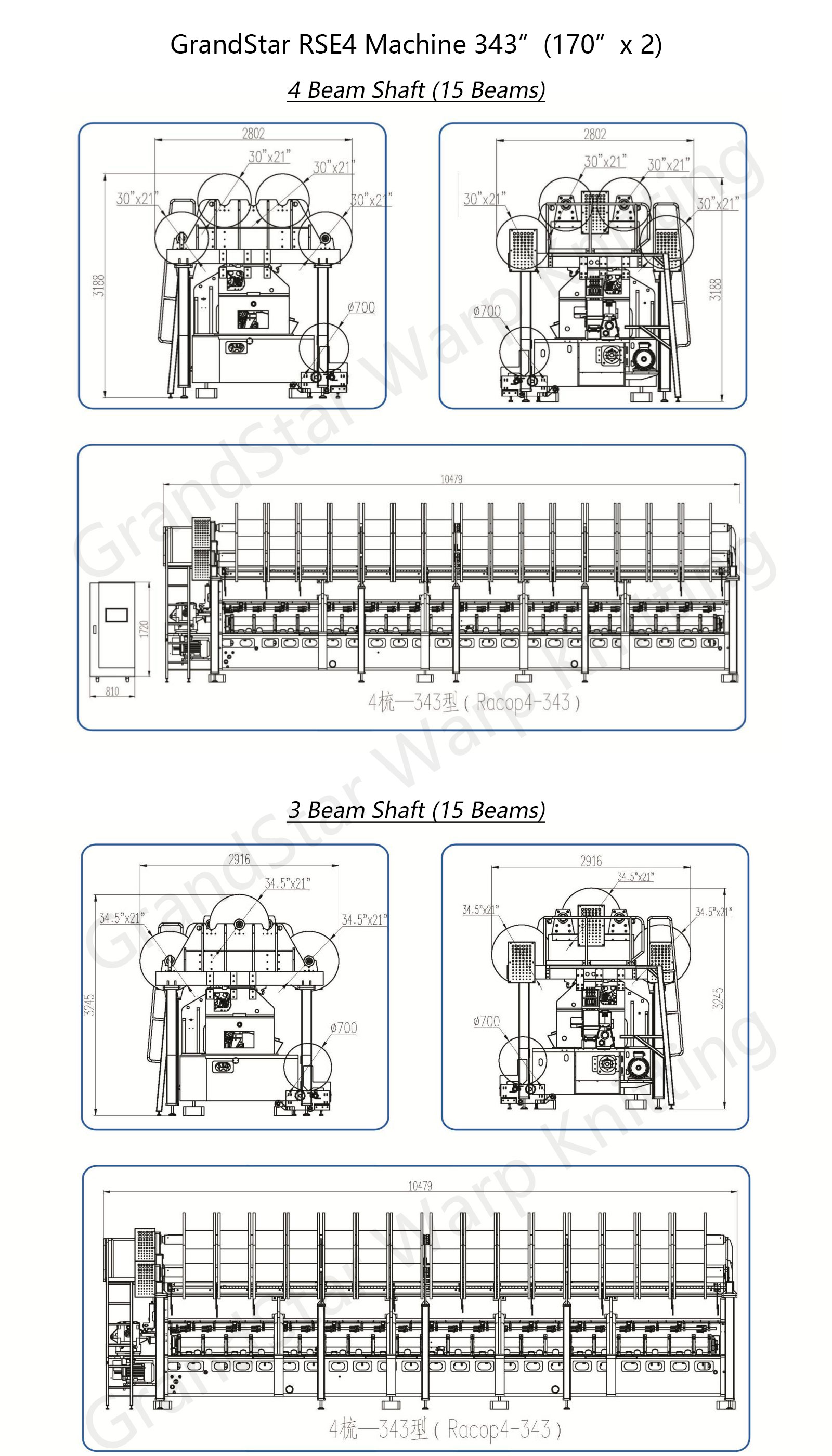

- Available widths: 340″ (8636 mm)

- Gauge options: E28 and E32 for precise fine and mid-gauge production

Knitting System — Bars & Elements

- Independent needle bar and tongue bar for optimized fabric formation

- Integrated stitch comb and knockover comb bars ensure flawless loop structure

- Four ground guide bars with carbon-fiber reinforcement for high-speed stability

Warp Beam Configuration

- Standard: Three warp beam positions with Ø 32″ flange sectional beams

- Optional: Four warp beam positions for Ø 21″ or Ø 30″ flange beams for increased flexibility

GrandStar® COMMAND SYSTEM — Intelligent Control Hub

- Advanced interface for real-time configuration, monitoring, and adjustment of all electronic functions

- Enhances productivity, consistency, and operational efficiency

Integrated Quality Monitoring

- Built-in LaserStop system for instant yarn break detection, reducing waste

- High-resolution camera ensures continuous visual quality control

Precision Yarn Let-Off Drive

- Each warp beam position equipped with electronically controlled let-off for uniform yarn tension

Fabric Take-Up System

- Electronically regulated take-up with geared motor drive

- Four-roller system ensures smooth advancement and consistent roll density

Batching Equipment

- Separate floor-standing cloth rolling unit for efficient large-batch handling

Pattern Drive Technology

- Robust N-drive with three pattern discs and integrated tempo change gear

- RSE 4-1: Up to 24 stitches for complex designs

- RSE 4: 16 stitches for streamlined production

- Optional EL-drive: Four electronically controlled motors, all guide bars shog up to 50 mm (extendable to 80 mm)

Electrical Specifications

- Speed-regulated main drive, total load: 25 kVA

- Power supply: 380V ±10%, three-phase

- Main power cable ≥ 4 mm², ground wire ≥ 6 mm² for safe, efficient operation

Optimized Oil Supply & Cooling

- Air-circulation heat exchanger with dirt-monitoring filtration

- Optional water-based heat exchanger for advanced climate control

Recommended Operating Conditions

- Temperature: 25°C ±6°C; Humidity: 65% ±10%

- Floor load capacity: 2000–4000 kg/m² for stable, vibration-free performance

Raschel Machines for High-End, Versatile Textile Production

ELASTIC RASCHEL MACHINES — Built for Unrivaled Efficiency and Precision

- World-Leading Speed & Width: Fastest, widest 4-bar Raschel machine globally for maximum output and versatility

- Productivity Meets Versatility: High productivity combined with limitless fabric design potential

- Superior Gauge Adaptability: Reliable performance across both fine and coarse gauges for diverse production needs

- Reinforced Carbon-Fiber Construction: Enhanced durability, reduced vibration, and extended machine lifespan

This elite Raschel solution empowers manufacturers to exceed production targets, drive innovation, and maintain a leading industry position.

GrandStar® — Setting Global Standards in Warp Knitting Innovation

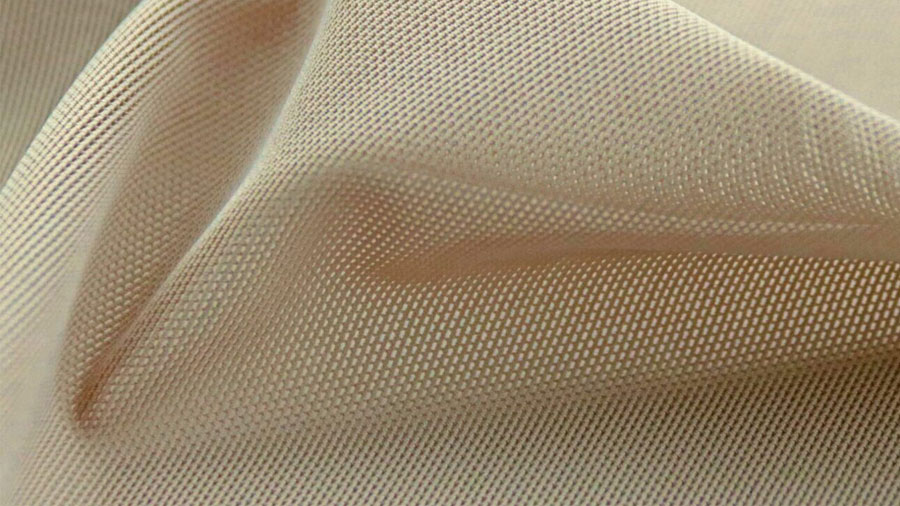

Powernet produced with E32 gauge offers an exceptionally fine mesh structure. The integration of 320 dtex elastane ensures high stretch modulus and excellent dimensional stability. Ideal for elastic lingerie, shapewear, and performance sportswear requiring controlled compression.

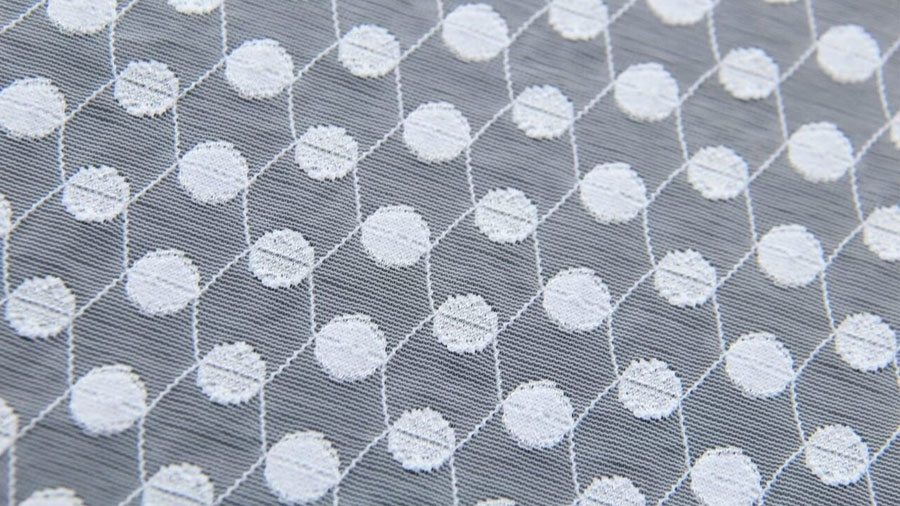

Knitwear with an embroidered appearance, produced on the RSE 6 EL. Two guide bars form the elastic ground, while two additional bars create a fine, high-sheen pattern with excellent contrast. The pattern yarns sink seamlessly into the base, delivering a refined, embroidery-like effect.

This transparent fabric combines a fine base structure, formed by a single ground guide bar, with a symmetrical pattern created by four additional guide bars. Light refraction effects are achieved by varying liners and filling yarns. The elastic design is ideal for outerwear and lingerie applications.

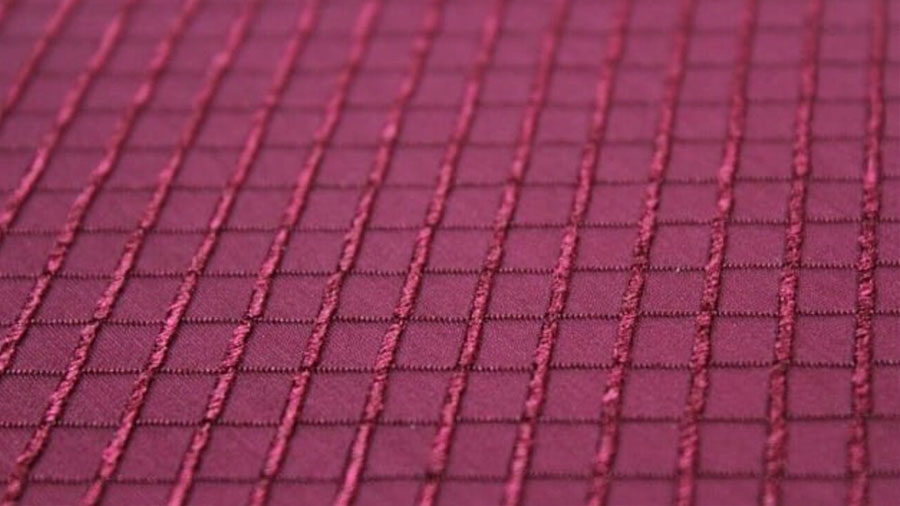

This elastic warp-knitted fabric features a distinctive geometric relief structure, delivering both flexibility and high dimensional stability. Its monochrome design enhances visual depth and provides an elegant shimmer under changing light—ideal for timeless, high-end lingerie applications.

This elastic fabric combines a transparent ground with opaque patterning, produced by four guide bars. The interplay of dull white and bright yarns creates subtle light effects, enhancing visual depth. Ideal for premium outerwear and lingerie requiring refined transparency.

This lightweight powernet fabric, engineered on a Raschel machine, delivers high stretch modulus, excellent breathability, and slight transparency. Ideal for sportswear applications, including mesh pockets, shoe inserts, and backpacks. Finished weight: 108 g/m².

Waterproof ProtectionEach machine is meticulously sealed with sea-safe packaging, providing robust defense against moisture and water damage throughout transit. |

International Export-Standard Wooden CasesOur high-strength composite wooden cases fully comply with global export regulations, ensuring optimal protection and stability during transportation. |

Efficient & Reliable LogisticsFrom careful handling at our facility to expert container loading at the port, every step of the shipping process is managed with precision to guarantee safe and timely delivery. |

CONTACT US

CONTACT US