Advancing Warp Knitting Technology: Optimizing Mechanical Performance for Industrial Applications

Warp knitting technology is undergoing a transformative evolution—driven by the growing demand for high-performance technical textiles in sectors like construction, geotextiles, agriculture, and industrial filtration. At the heart of this transformation lies an enhanced understanding of how yarn path configuration, guide bar lapping plans, and directional loading affect the mechanical behavior of warp-knitted fabrics.

This article introduces pioneering advancements in warp knitting mesh design, grounded in empirical findings from HDPE (high-density polyethylene) monofilament fabrics. These insights reshape how manufacturers approach product development, optimizing warp-knitted fabrics for real-world performance, from soil stabilization meshes to advanced reinforcement grids.

Understanding Warp Knitting: Engineered Strength through Precision Looping

Unlike woven textiles where yarns intersect at right angles, warp knitting constructs fabrics through continuous loop formation along the warp direction. Guide bars, each threaded with yarn, follow programmed swinging (side-to-side) and shogging (front-back) motions, producing varied underlaps and overlaps. These loop profiles directly influence a fabric’s tensile strength, elasticity, porosity, and multidirectional stability.

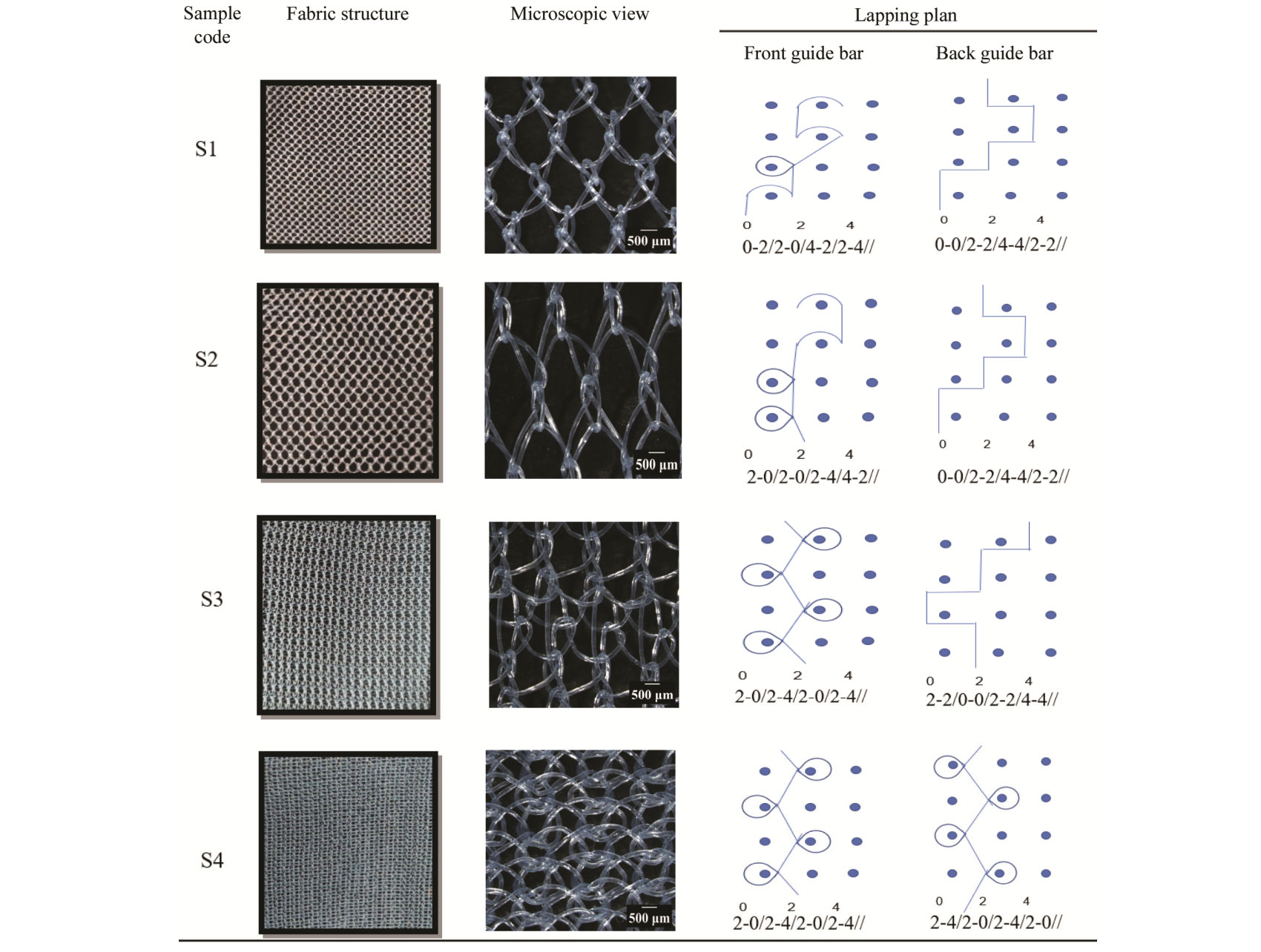

The research identifies four custom warp-knit structures—S1 to S4—engineered using different lapping sequences on a Tricot warp knitting machine with two guide bars. By altering the interplay between open and closed loops, each structure demonstrates distinct mechanical and physical behaviors.

Technological Innovation: Fabric Structures and Their Mechanical Impact

1. Customized Lapping Plans and Guide Bar Movement

- S1: Combines front guide bar closed loops with back guide bar open loops, forming a rhombus-style grid.

- S2: Features alternating open and closed loops by the front guide bar, enhancing porosity and diagonal resilience.

- S3: Prioritizes loop tightness and minimized yarn angle to achieve high stiffness.

- S4: Employs closed loops on both guide bars, maximizing stitch density and mechanical strength.

2. Mechanical Directionality: Unlocking Strength Where It Matters

Warp-knitted mesh structures exhibit anisotropic mechanical behavior—meaning their strength changes depending on load direction.

- Wales direction (0°): Highest tensile strength due to yarn alignment along the primary load-bearing axis.

- Diagonal direction (45°): Moderate strength and flexibility; useful in applications requiring resilience to shear and multi-directional force.

- Course direction (90°): Lowest tensile strength; least yarn alignment in this orientation.

For instance, sample S4 demonstrated superior tensile strength in the wales direction (362.4 N) and exhibited the highest bursting resistance (6.79 kg/cm²)—making it ideal for high-load applications like geogrids or concrete reinforcement.

3. Elastic Modulus: Controlling Deformation for Load-Bearing Efficiency

Elastic modulus measures how much a fabric resists deformation under load. The findings show:

- S3 achieved the highest modulus (24.72 MPa), attributed to nearly linear yarn paths in the back guide bar and tighter loop angles.

- S4, while slightly lower in stiffness (6.73 MPa), compensates with superior multidirectional load tolerance and burst strength.

This insight empowers engineers to select or develop mesh structures aligned with application-specific deformation thresholds—balancing stiffness with resilience.

Physical Properties: Engineered for Performance

1. Stitch Density and Fabric Cover

S4 leads in fabric cover due to its high stitch density (510 loops/in²), offering improved surface uniformity and load distribution. High fabric cover enhances durability and light-blocking properties—valuable in protective mesh, sun shading, or containment applications.

2. Porosity and Air Permeability

S2 boasts the highest porosity, attributed to larger loop openings and looser knit construction. This structure is ideal for breathable applications such as shade nets, agricultural covers, or lightweight filtration fabrics.

Real-World Applications: Built for Industry

- Geotextiles and Infrastructure: S4 structures offer unmatched reinforcement for soil stabilization and retaining wall applications.

- Construction and Concrete Reinforcement: Meshes with high modulus and durability provide effective crack control and dimensional stability in concrete structures.

- Agriculture and Shade Netting: S2’s breathable structure supports temperature regulation and crop protection.

- Filtration and Drainage: Porosity-tuned fabrics enable effective water flow and particle retention in technical filtration systems.

- Medical and Composite Use: Lightweight, high-strength meshes enhance functionality in surgical implants and engineered composites.

Manufacturing Insights: HDPE Monofilament as a Game-Changer

HDPE monofilament plays a pivotal role in achieving superior mechanical and environmental performance. With high tensile strength, UV resistance, and long-term durability, HDPE makes warp-knitted fabrics suitable for harsh, load-bearing, and outdoor applications. Its strength-to-weight ratio and thermal stability make it ideal for reinforcement meshes, geogrids, and filtration layers.

Future Outlook: Toward Smarter Warp Knitting Innovation

- Smart Warp Knitting Machines: AI and digital twin technologies will drive adaptive guide bar programming and real-time structure optimization.

- Application-Based Fabric Engineering: Warp-knit structures will be engineered based on stress modeling, porosity targets, and material load profiles.

- Sustainable Materials: Recycled HDPE and bio-based yarns will power the next wave of eco-friendly warp-knitted solutions.

Final Thoughts: Engineering Performance from the Yarn Up

This study confirms that mechanical capabilities in warp-knitted fabrics are fully engineerable. By tuning lapping plans, loop geometry, and yarn alignment, manufacturers can develop warp-knitted mesh with performance tailored to demanding industrial needs.

At our company, we are proud to lead this transformation—offering warp knitting machinery and material solutions that help our partners build stronger, smarter, and more sustainable products.

Let us help you engineer the future—one loop at a time.

Post time: Jul-18-2025

CONTACT US

CONTACT US