Advancing Warp Knitting Technology: Optimizing Mechanical Performance for Industrial Applications

Warp knitting thev naus laus zis tau dhau los ua qhov hloov pauv hloov pauv-tsav los ntawm kev xav tau loj hlob rau kev ua haujlwm siab ntawm textiles hauv cov haujlwm xws li kev tsim kho, geotextiles, kev ua liaj ua teb, thiab kev pom kev lag luam. Nyob rau hauv lub plawv ntawm qhov kev hloov pauv no yog qhov kev nkag siab zoo ntawm kev teeb tsa txoj kev xov paj li cas, kev qhia bar lapping cov phiaj xwm, thiab kev taw qhia kev thauj khoom cuam tshuam rau cov neeg kho tshuab tus cwj pwm ntawm warp-knitted fabrics.

Tsab ntawv xov xwm no qhia txog kev txhim kho kev txhim kho hauv warp knitting mesh tsim, hauv paus hauv kev tshawb pom pom los ntawm HDPE (high-density polyethylene) monofilament fabrics. Cov kev nkag siab no hloov kho li cas cov tuam txhab tsim khoom lag luam txhim kho, ua kom zoo dua cov ntaub npuag warp-knitted rau kev ua tau zoo hauv ntiaj teb, los ntawm cov av stabilization meshes mus rau cov txheej txheem ntxiv.

Nkag siab Warp Knitting: Engineered Strength los ntawm Precision Looping

Tsis zoo li woven textiles qhov twg yarns sib tshuam ntawm txoj cai kaum, warp knitting tsim fabrics los ntawm nruam voj tsim raws lub warp kev taw qhia. Qhia tuav, txhua lub xov paj nrog cov xov paj, ua raws li programmed swinging (sab-rau-sab) thiab shogging (pem hauv ntej-rov qab) cov lus tsa suab, ua ntau yam hauv qab thiab sib tshooj. Cov voj voos no ncaj qha cuam tshuam cov ntaub lub zog tensile, elasticity, porosity, thiab multidirectional stability.

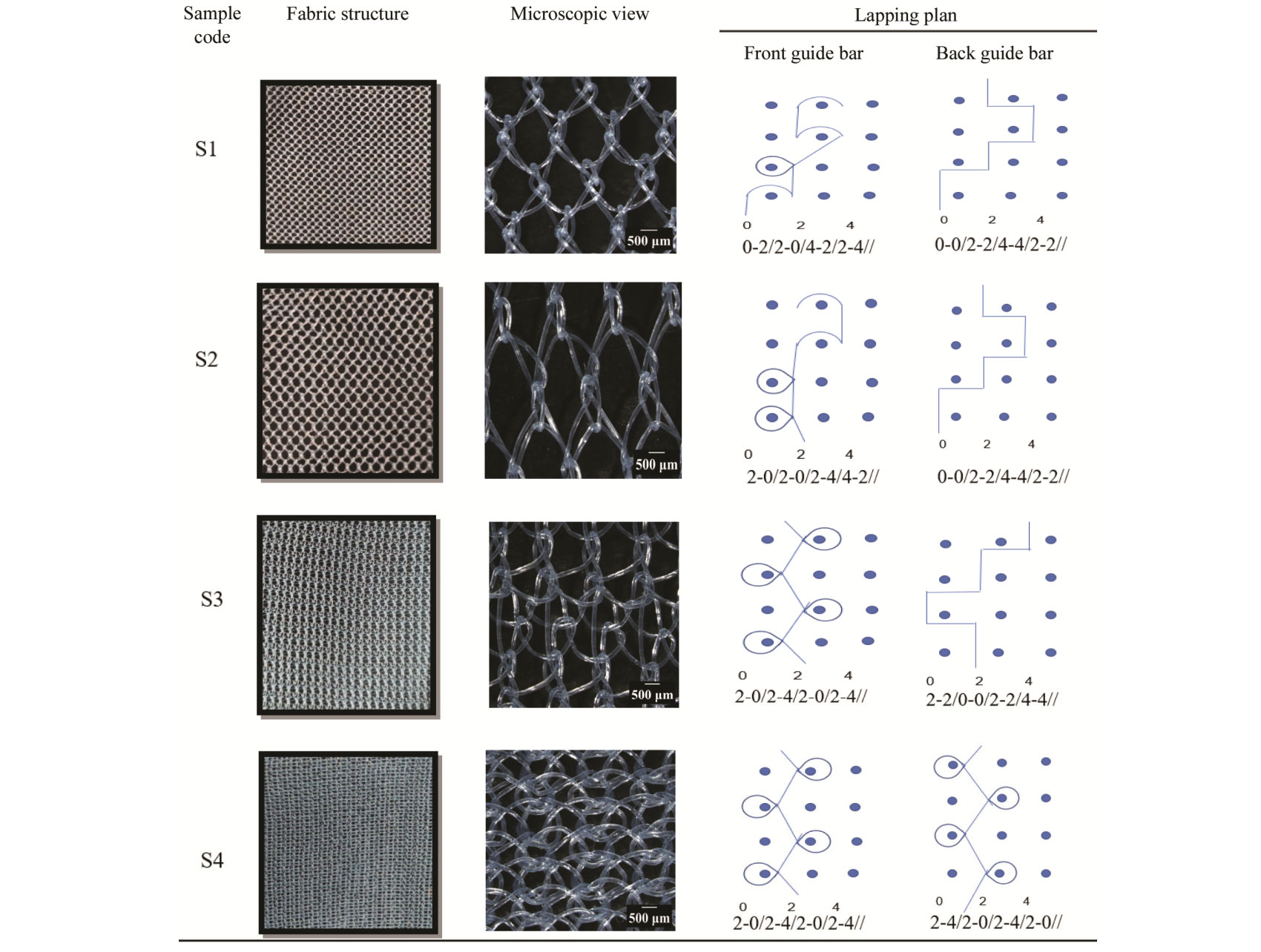

Kev tshawb fawb txheeb xyuas plaub qhov kev cai warp-knit qauv-S1 rau S4-engineered siv sib txawv lapping sequences ntawm lub Tricot warp knitting tshuab nrog ob daim ntawv qhia tuav. Los ntawm kev hloov pauv qhov sib cuam tshuam ntawm qhov qhib thiab kaw lub voj voog, txhua tus qauv qhia qhov txawv ntawm txhua yam thiab lub cev tus cwj pwm.

Technological Innovation: Fabric Structures thiab Lawv Mechanical Impact

1. Customized Lapping Plans thiab Guide Bar Movement

- S1:Ua ke rau pem hauv ntej phau ntawv qhia bar kaw loops nrog rov qab qhia bar qhib loops, tsim ib daim phiaj rhombus.

- S2:Nta alternating qhib thiab kaw loops los ntawm pem hauv ntej phau ntawv qhia bar, pab txhawb porosity thiab kab pheeb ces kaum resilience.

- S3:Prioritizes voj nruj thiab minimized xov lub kaum sab xis kom ua tau siab nruj.

- S4:Ua hauj lwm kaw loops ntawm ob qho tib si qhia tuav, maximizing stitch ceev thiab mechanical zog.

2. Mechanical Directionality: Xauv lub zog qhov twg nws tseem ceeb

Warp-knitted mesh structures nthuav tawm anisotropic mechanical cwj pwm - txhais tau tias lawv lub zog hloov pauv nyob ntawm kev coj ua.

- Wales kev taw qhia (0 °):Lub zog tensile siab tshaj plaws vim yog cov xov paj sib dhos raws li thawj qhov kev thauj khoom axis.

- Diagonal kev taw qhia (45 °):Lub zog nruab nrab thiab yoog raws; pab tau nyob rau hauv daim ntawv thov yuav tsum tau resilience rau shear thiab multi-directional quab yuam.

- Kev taw qhia ntawm chav kawm (90 °):Tsawg tensile zog; yam tsawg kawg yarn alignment hauv no orientation.

Piv txwv li, cov qauv S4 tau pom tias muaj zog tensile zog nyob rau hauv wales kev taw qhia (362.4 N) thiab nthuav tawm qhov siab tshaj plaws bursting resistance (6.79 kg / cm²) - ua rau nws zoo tagnrho rau high-load daim ntaub ntawv xws li geogrids los yog pob zeb reinforcement.

3. Elastic Modulus: Tswj Deformation rau Load-Bearing Efficiency

Elastic modulus ntsuas ntau npaum li cas cov ntaub tiv thaiv deformation nyob rau hauv load. Cov kev tshawb pom qhia tias:

- S3ua tiav qhov siab tshaj plaws modulus (24.72 MPa), ntaus nqi rau ze li ntawm cov xov paj txoj hauv kev hauv qab cov lus qhia bar thiab lub voj voog nruj dua.

- S4, thaum me ntsis qis hauv qhov tawv nqaij (6.73 MPa), them nyiaj nrog kev ua haujlwm siab ua haujlwm siab thiab tawg lub zog.

Qhov kev pom no txhawb nqa cov kws tsim khoom los xaiv lossis tsim cov qauv mesh ua raws li daim ntawv thov tshwj xeeb deformation pib - ntsuas qhov nruj nrog kev ua haujlwm.

Physical Properties: Engineered for Performance

1. Stitch ceev thiab ntaub npog

S4ua rau hauv cov ntaub npog vim nws qhov siab plooj ntom ntom (510 loops / in²), muab kev txhim kho saum npoo zoo sib xws thiab thauj khoom xa tawm. Cov ntaub npog siab txhim khu kev ua haujlwm ntev thiab lub teeb thaiv kev tiv thaiv - muaj txiaj ntsig hauv kev tiv thaiv mesh, hnub ci ntxoov ntxoo, lossis daim ntawv thov ntim.

2. Porosity thiab huab cua permeability

S2boasts lub siab tshaj plaws porosity, ntaus nqi rau lub voj loj qhib thiab looser knit siv. Cov qauv no yog qhov zoo tagnrho rau kev siv ua pa xws li ntxoov ntxoo nets, npog ua liaj ua teb, lossis cov ntaub ntawv pom kev sib sib zog nqus.

Daim Ntawv Thov Ntiaj Teb tiag: Ua rau Kev Lag Luam

- Geotextiles thiab Infrastructure:S4 cov qauv muab kev txhawb nqa tsis sib xws rau cov av stabilization thiab khaws cov ntawv thov phab ntsa.

- Kev tsim kho thiab kev ua vaj tse pob zeb:Meshes nrog siab modulus thiab durability muab kev tswj kom tawg tau zoo thiab qhov ruaj khov nyob rau hauv cov qauv pob zeb.

- Ua liaj ua teb thiab ntxoov ntxoo Netting:S2 tus qauv breathable txhawb kev ntsuas kub thiab kev tiv thaiv qoob loo.

- Filtration thiab Drainage:Porosity-tuned fabrics pab kom cov dej ntws zoo thiab cov khoom khaws cia hauv cov tshuab lim dej.

- Kev siv kho mob thiab sib xyaw:Lub teeb yuag, lub zog siab meshes txhim kho kev ua haujlwm hauv kev phais kev cog hniav thiab cov khoom sib xyaw ua ke.

Manufacturing Insights: HDPE Monofilament li Game-Changer

HDPE monofilament plays lub luag haujlwm tseem ceeb hauv kev ua tiav kev ua haujlwm zoo tshaj plaws thiab ib puag ncig. Nrog lub zog tensile siab, UV tsis kam, thiab lub sijhawm ntev, HDPE ua rau cov ntaub npuag npuag haum rau hnyav, thauj khoom, thiab siv sab nraum zoov. Nws lub zog-rau-hnyav piv thiab thermal stability ua rau nws zoo tagnrho rau kev txhawb nqa meshes, geogrids, thiab filtration txheej.

Yav tom ntej Outlook: Mus rau Smarter Warp Knitting Innovation

- Ntse Warp Knitting Tshuab:AI thiab digital ntxaib thev naus laus zis yuav ua rau muaj kev hloov pauv ntawm cov lus qhia bar programming thiab cov qauv siv sijhawm tiag tiag.

- Application-Based Fabric Engineering:Warp-knit structures yuav raug tsim los ntawm kev tsim qauv kev ntxhov siab, lub hom phiaj porosity, thiab cov khoom thauj khoom.

- Sustainable Materials:Rov ua dua HDPE thiab bio-based yarns yuav ua rau lub zog tom ntej ntawm eco-friendly warp-knitted daws.

Kev xav zaum kawg: Engineering Performance los ntawm Xov Paj

Txoj kev tshawb no tau lees paub tias muaj peev xwm siv tshuab hauv warp-knitted fabrics yog tag nrho engineerable. Los ntawm kev hloov kho cov phiaj xwm, lub voj geometry, thiab cov xov paj sib dhos, cov tuam ntxhab tuaj yeem tsim warp-knitted mesh nrog kev ua tau zoo raws li kev xav tau ntawm kev lag luam.

Ntawm peb lub tuam txhab, peb zoo siab los ua tus coj qhov kev hloov pauv no - muab cov khoom siv warp knitting thiab cov kev daws teeb meem uas pab peb cov neeg koom tes tsim kom muaj zog, ntse dua, thiab cov khoom lag luam ruaj khov.

Cia peb pab koj tsim lub neej yav tom ntej-ib lub voj voog ib zaug.

Post lub sij hawm: Lub Xya hli ntuj-18-2025

Tiv tauj peb

Tiv tauj peb