Theknoloji e Tsoelang Pele ea Warp Knitting: Ho Ntlafatsa Ts'ebetso ea Mechini bakeng sa Likopo tsa Liindasteri

Theknoloji ea ho loha ea Warp e ntse e tsoela pele ho fetoha - e tsamaisoang ke tlhokahalo e ntseng e hola ea masela a sebetsang hantle haholo makaleng a kang a kaho, geotextiles, temo le tlhoekiso ea indasteri. Bohareng ba phetoho ena ho na le kutloisiso e ntlafalitsoeng ea hore na tlhophiso ea tsela ea likhoele, meralo ea ho roala lithapo tsa tataiso, le ho laela ka tsela li amang boits'oaro ba masela a lohiloeng ka warp.

Sengoliloeng sena se hlahisa tsoelo-pele ea boqapi ba marang-rang a marang-rang a marang-rang, a thehiloeng ho liphuputso tse matla tse tsoang ho masela a monofilament a HDPE (high-density polyethylene). Litlhaloso tsena li fetola tsela eo bahlahisi ba atamelang nts'etsopele ea lihlahisoa, ho ntlafatsa masela a lohiloeng ka warp bakeng sa ts'ebetso ea sebele ea lefats'e, ho tloha ho li-meshes tsa ho tsitsisa mobu ho ea ho li-grids tse matlafatsang tse tsoetseng pele.

Ho utloisisa Warp Knitting: Matla a Engineered ka Precision Looping

Ho fapana le masela a lohiloeng moo likhoele li kopanang teng ka likhutlo tse nepahetseng, ho loha ha warp ho etsa masela ka mokhoa o tsoelang pele oa ho etsa loop ho latela tsela ea warp. Litsupa tse tataisang, e 'ngoe le e 'ngoe e khoele ka khoele, e latela metsamao e hlophisitsoeng (ho ea ka lehlakoreng) le ho sisinyeha (ka pele-morao), e hlahisang mekhabiso e fapaneng e ka tlase le e fetang. Li-loop profiles tsena li susumetsa ka ho toba matla a lesela a tsitsitseng, elasticity, porosity, le botsitso ba litsela tse ngata.

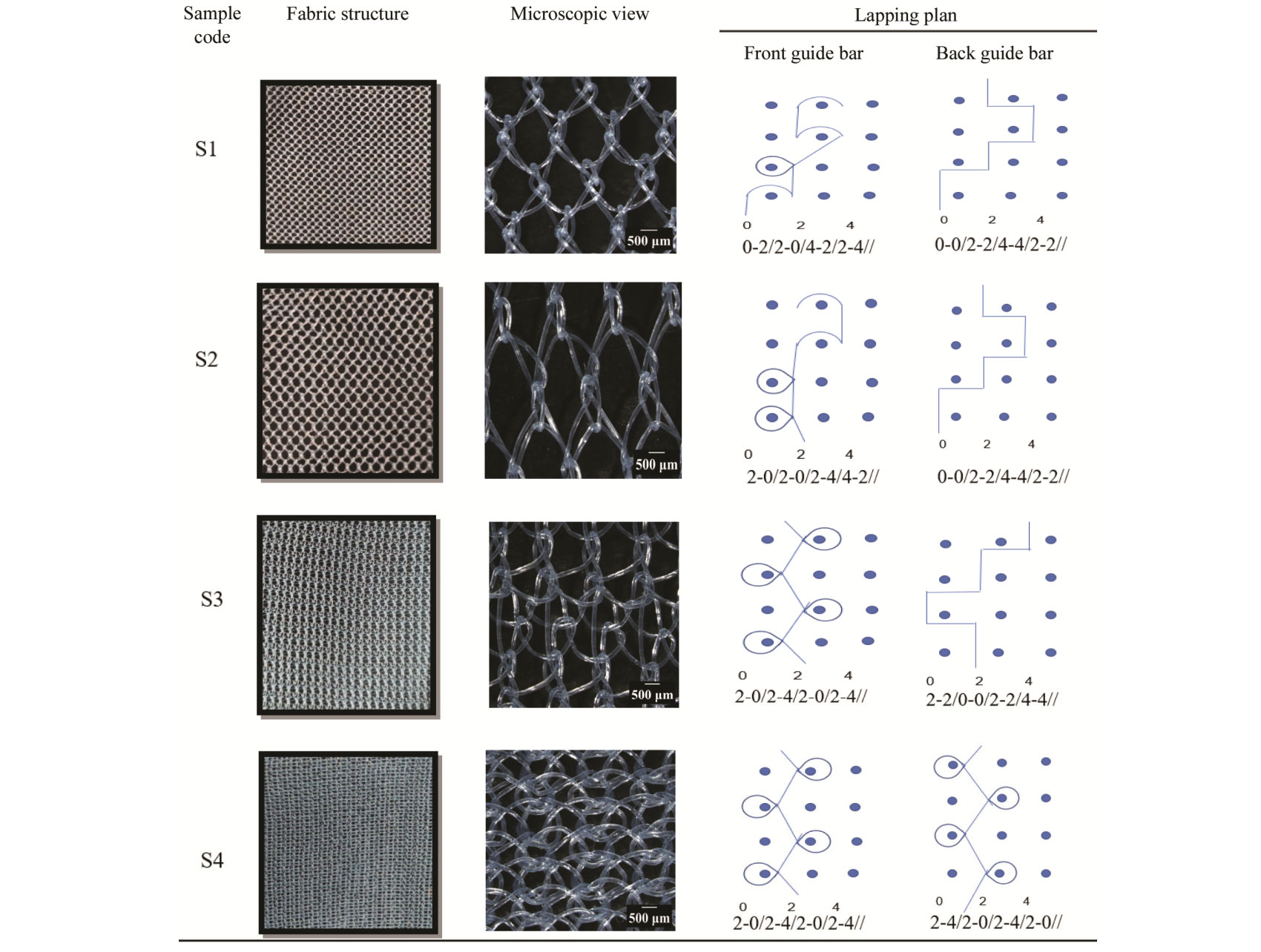

Patlisiso e supa meaho e mene e lohiloeng e lohiloeng - S1 ho ea ho S4 - e entsoe ka tatellano e fapaneng ea ho roala mochini o lohang oa Tricot o nang le maballo a mabeli a tataiso. Ka ho fetola tšebelisano lipakeng tsa liloko tse bulehileng le tse koetsoeng, sebopeho se seng le se seng se bonts'a boits'oaro bo ikhethileng ba boits'oaro le ba 'mele.

Boqapi ba Theknoloji: Mehaho ea Lesela le Tšusumetso ea Tsona ea Mechini

1. Customized Lapping Plans le Guide Bar Movement

- S1:E kopanya mekoallo e ka pele e koetsoeng le mekoallo ea tataiso e ka morao, e etsa marang-rang a mofuta oa rhombus.

- S2:Likarolo tse fapanyetsanoang lilopi tse bulehileng le tse koetsoeng ka bara ea tataiso e ka pele, e matlafatsang porosity le botsitso ba diagonal.

- S3:E etelletsa pele ho tiea ha loop le ho fokotsa khoele ea khoele ho fihlela boima bo phahameng.

- S4:E sebelisa li-loops tse koetsoeng litšeng tse peli tsa tataiso, e holisa sekhahla sa stitch le matla a mochini.

2. Mechanical Directionality: Ho notlolla Matla moo ho leng Bohlokoa

Mehaho ea mesh e entsoeng ka Warp e bonts'a boits'oaro ba mochini oa anisotropic-ho bolelang hore matla a bona a fetoha ho latela tataiso ea mojaro.

- Tsela ea Wales (0°):Matla a phahameng ka ho fetesisa ka lebaka la ho hokahana ha khoele haufi le axis ea mantlha e jarang moroalo.

- Tsela e diagonal (45°):Matla a itekanetseng le ho feto-fetoha ha maemo; e sebetsang lits'ebetsong tse hlokang mamello ho kuta le matla a fapaneng.

- Tsela ea thupelo (90°):Matla a tlaase ka ho fetisisa; tatellano e nyane ea khoele mokhoeng ona.

Mohlala, sampole ea S4 e bonts'itse matla a phahameng a ho tiea sebakeng sa wales (362.4 N) 'me e bonts'a khanyetso e phahameng ka ho fetesisa (6.79 kg/cm²)—e leng se etsang hore e be e loketseng bakeng sa lits'ebetso tse ngata tse kang li-geogrid kapa li-concrete tse matlafatsang.

3. Elastic Modulus: Ho Laola Phetoho bakeng sa Boiketlo ba ho Jara Moroalo

Elastic modulus e lekanya hore na lesela le hanana le deformation hakae tlas'a mojaro. Liphuputso li bontša:

- S3e fihletse modulus e phahameng ka ho fetisisa (24.72 MPa), e hlahisoang ke litselana tse batlang li lekana ka har'a bara ea tataiso e ka morao le li-angles tse thata tsa loop.

- S4, ha e ntse e fokotseha hanyenyane ka ho satalla (6.73 MPa), e lefella ho mamella boima bo phahameng ba litsela tse ngata le matla a phatlohileng.

Kutloisiso ena e matlafatsa baenjiniere ho khetha kapa ho nts'etsapele meaho ea marang-rang e tsamaellanang le metheo e ikhethileng ea ts'ebeliso - ho leka-lekanya ho satalla le mamello.

Thepa ea 'Mele: E Entsoe bakeng sa Ts'ebetso

1. Sekoahelo sa Motsu le Sekoahelo sa Lesela

S4e etella pele ka sekoaelo sa lesela ka lebaka la ho teteana ha eona ho holimo (510 loops/in²), e fanang ka ho tšoana ho ntlafalitsoeng le kabo ea mojaro. Sekoaelo se phahameng sa masela se matlafatsa nako e telele le thepa e thibelang khanya—e bohlokoa ka har'a letlooeng le sireletsang, ho shading letsatsing kapa ho koaheloa.

2. Porosity le Air Permeability

S2e na le porosity e phahameng ka ho fetisisa, e hlahisoang ke menyetla e meholo ea loop le kaho e lohiloeng e lohiloeng. Sebopeho sena se loketse lisebelisoa tse phefumolohang tse kang matlooa a moriti, likoahelo tsa temo, kapa masela a bobebe a ho hloekisa.

Likopo tsa 'Nete tsa Lefatše: E Hahiloe bakeng sa Indasteri

- Geotextiles le Infrastructure:Mehaho ea S4 e fana ka matlafatso a ke keng a lekanngoa bakeng sa ho tsitsisa mobu le ho boloka lisebelisoa tsa marako.

- Kaho le Matlafatso ea Konkreite:Meshes e nang le modulus e phahameng le e tšoarellang e fana ka taolo e sebetsang ea ho peperana le botsitso bo boholo meahong ea konkreite.

- Temo le Neha ea Moriti:Sebopeho se phefumolohang sa S2 se ts'ehetsa taolo ea mocheso le ts'ireletso ea lijalo.

- Tlhophiso le Phallo ea metsi:Masela a hlophisitsoeng a porosity a thusa ho phalla hantle ha metsi le ho boloka likaroloana ho litsamaiso tsa tekheniki tsa filtration.

- Tšebeliso ea bongaka le e kopaneng:Li-meshes tse bobebe, tse matla haholo li ntlafatsa ts'ebetso ea li-implants tsa ho buoa le ho kopanya metsoako.

Maikutlo a Tlhahiso: HDPE Monofilament e le Game-Changer

HDPE monofilament e bapala karolo ea bohlokoa ho finyelleng ts'ebetso e phahameng ea mochini le tikoloho. Ka matla a phahameng a ho tsieleha, khanyetso ea UV, le ho tšoarella ha nako e telele, HDPE e etsa masela a lohiloeng ka warp hore a tšoanelehe bakeng sa lisebelisoa tse thata, tse jarang meroalo le tsa kantle. Karo-karolelano ea matla ho boima ba 'mele le botsitso ba mocheso li etsa hore e be e loketseng bakeng sa meshes e matlafatsang, li-geogrid le likarolo tsa filtration.

Maikutlo a Bokamoso: Ho Leba Popontšo ea Smarter Warp Loha

- Mechini ea ho Loha ea Smart Warp:AI le theknoloji ea mafahla ea dijithale li tla tsamaisa mananeo a litataiso tse feto-fetohang le ntlafatso ea sebopeho sa nako ea nnete.

- Boenjiniere ba Masela bo Thehiloeng ho Kopo:Mehaho ea Warp-knit e tla etsoa e ipapisitse le mohlala oa khatello ea maikutlo, lipehelo tsa porosity, le profiles ea thepa ea thepa.

- Lisebelisoa tsa Moshoelella:HDPE e tsosolositsoeng le likhoele tse thehiloeng linthong tse phelang li tla matlafatsa leqhubu le latelang la litharollo tse lohiloeng tse lohiloeng ka eco-friendly.

Mehopolo ea ho Qetela: Ts'ebetso ea Boenjineri ho tloha ho khoele ea holimo

Phuputso ena e tiisa hore bokhoni ba mochine masela a lohiloeng ka warp bo ka etsoa ka botlalo. Ka ho lokisa meralo ea li-lapping, loop geometry, le tlhophiso ea khoele, bahlahisi ba ka etsa mesh e lohiloeng ka warp e nang le ts'ebetso e lumellanang le litlhoko tse boima tsa indasteri.

K'hamphaning ea rona, re motlotlo ho etella pele phetoho ena - ho fana ka mochini o lohang oa warp le tharollo ea thepa e thusang balekane ba rona ho haha lihlahisoa tse matla, tse bohlale le tse tšoarellang.

E re re u thuse ho etsa boenjiniere ba bokamoso—leqhubu le le leng ka nako.

Nako ea poso: Jul-18-2025

ITEANYE LE RONA

ITEANYE LE RONA