EBA/EBC (Let-off) System For Warp Knitting Machine

Precision EBA/EBC Systems for Warp Knitting Machines

Next-Generation Electronic Let-Off Solutions from GrandStar

At GrandStar, we are at the forefront of EBA (Electronic Beam Adjustment) and EBC (Electronic Beam Control) system innovation—specialized for warp knitting machines. With a relentless commitment to technological advancement, we have continuously refined our servo motor control technology, delivering faster response times, higher load capacity, and superior fabric quality.

Engineered for Modernization and Performance

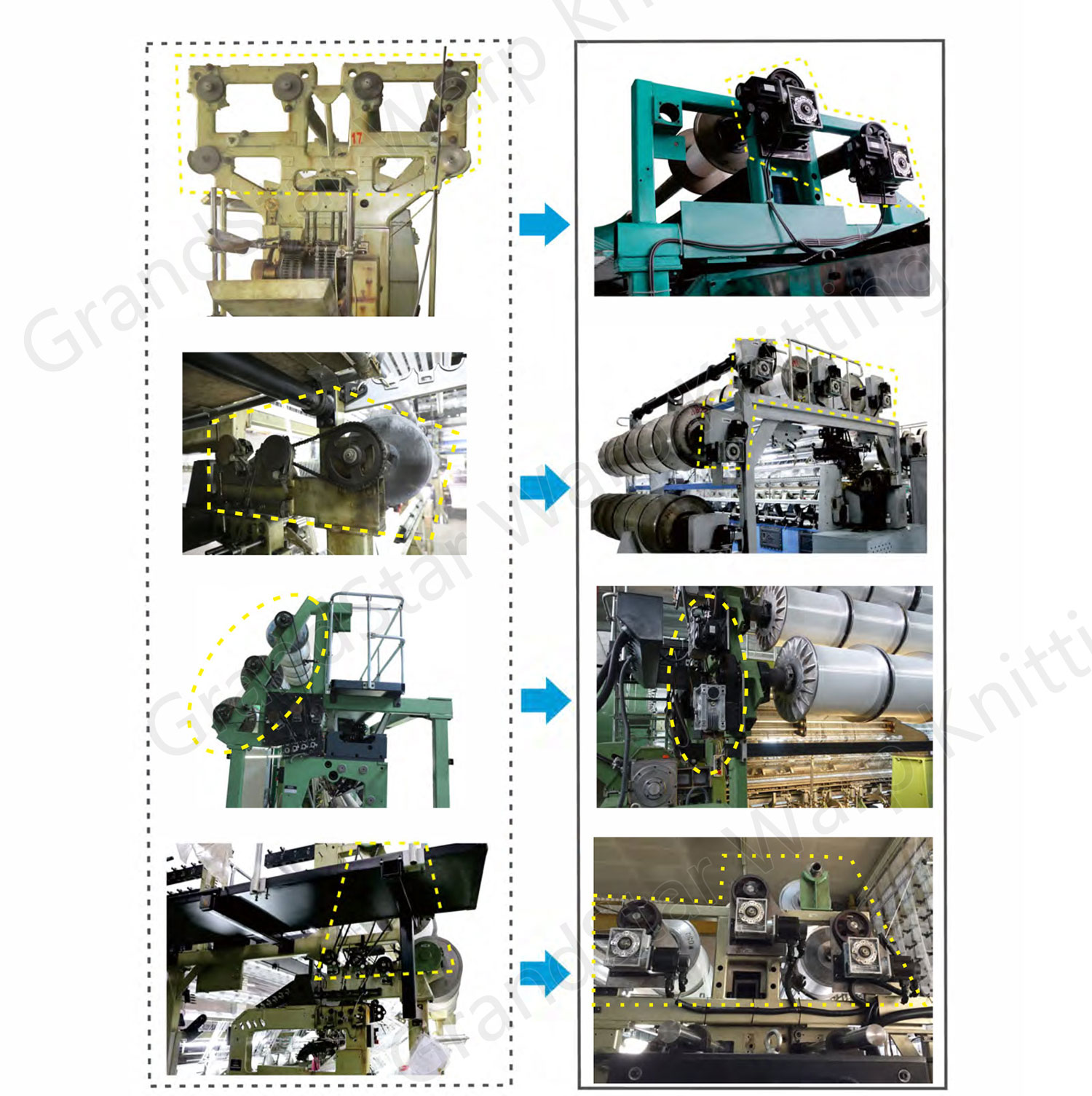

Our EBA/EBC systems are not only designed for new machines but also play a vital role in revitalizing older models. By upgrading outdated mechanical let-off mechanisms to intelligent electronic systems, we breathe new life into legacy warp knitting machines—improving precision, productivity, and return on investment.

Key Features and Competitive Advantages

1. Full Retrofitting Capability

We offer tailored retrofitting solutions for all major legacy warp knitting models. This transformation replaces mechanical let-off with high-precision EBA/EBC systems, enabling customers to extend machine lifespan while adopting modern production standards.

2. Advanced Stop-Motion Compensation

Our system integrates intelligent stop-motion compensation to eliminate horizontal lines or defects during sudden halts. This ensures fabric consistency even during unexpected stops—reducing waste and maximizing quality.

3. Ultra-High-Speed Compatibility

Designed to support today’s most demanding production lines, our EBA/EBC systems enable seamless operation at speeds exceeding 4,000 RPM, making them ideal for high-speed tricot and warp knitting machines.

4. High Torque for Heavy Beam Loads

We provide customized high-power electrical configurations for each machine’s load demand. Whether operating 390-inch or 40-inch beams, our systems maintain stable and synchronized let-off, even at maximum speeds.

5. IoT-Enabled Smart Manufacturing

All our EBA/EBC systems are fully compatible with IoT environments. Real-time data transmission, predictive maintenance alerts, and integration into smart factory networks are built-in features—positioning your production for Industry 4.0.

Why Choose GrandStar?

Unlike generic electronic let-off providers, we specialize exclusively in warp knitting applications. Our deep understanding of warp tension dynamics, machine-specific load profiles, and servo-motor behavior ensures that every EBA/EBC system we deliver is optimized for efficiency, durability, and unmatched precision.

Our solutions outperform standard models used by other suppliers in areas such as:

- Response time under sudden stop/start conditions

- Load stability at ultra-high RPMs

- Beam-specific torque customization

- Integration flexibility with various machine brands

Transform your warp knitting operation with intelligent control and unmatched stability.

Contact our technical team today to explore retrofitting options or request a custom configuration.

CONTACT US

CONTACT US