EL System For Warp Knitting Machine

GrandStar Advanced EL System for Warp Knitting Machines

Precision. Performance. Possibilities.

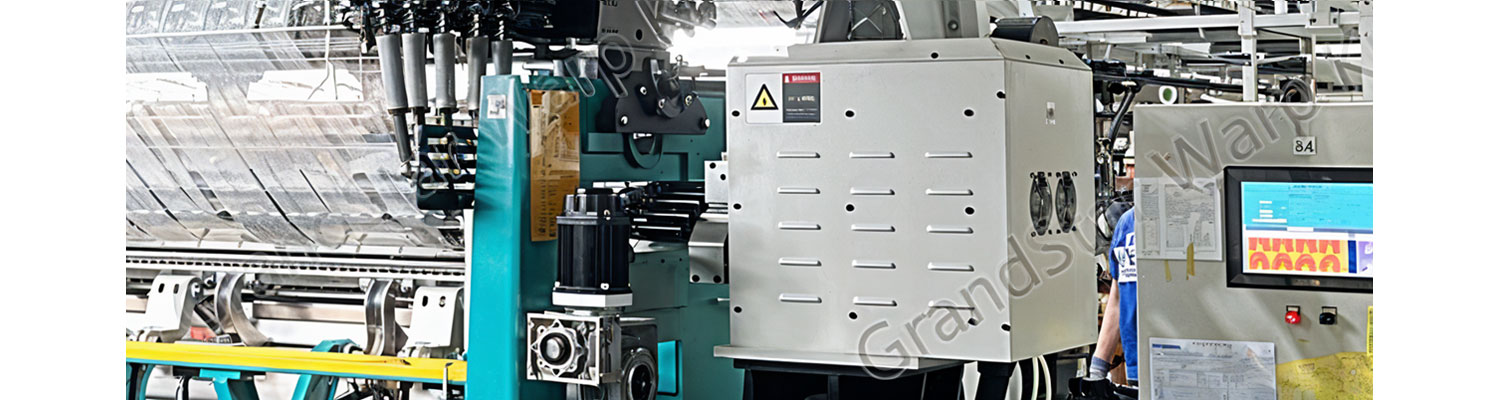

Since 2008, GrandStar has led the global evolution of Electronic Let-off (EL) technology for warp knitting machines. With over 10,000 machines worldwide equipped with our EL system, we have earned a reputation as an industry pioneer in EL-driven control, setting new benchmarks for speed, precision, and versatility.

Driven by relentless innovation, our EL system continues to undergo advanced technical iterations, especially in servo motor responsiveness and load capacity. This continuous development ensures GrandStar EL systems remain at the forefront of performance — empowering manufacturers to achieve exceptional results across diverse warp knitting applications.

Why Leading Manufacturers Trust GrandStar EL Systems

1. Exceptional Movement Range for Complex Applications

GrandStar EL systems deliver a market-leading 80mm movement range, with options for even greater displacement. This extended range enables the development of specialized, high-complexity processes on both Tricot and Raschel warp knitting machines — unlocking new design possibilities and expanding production capabilities.

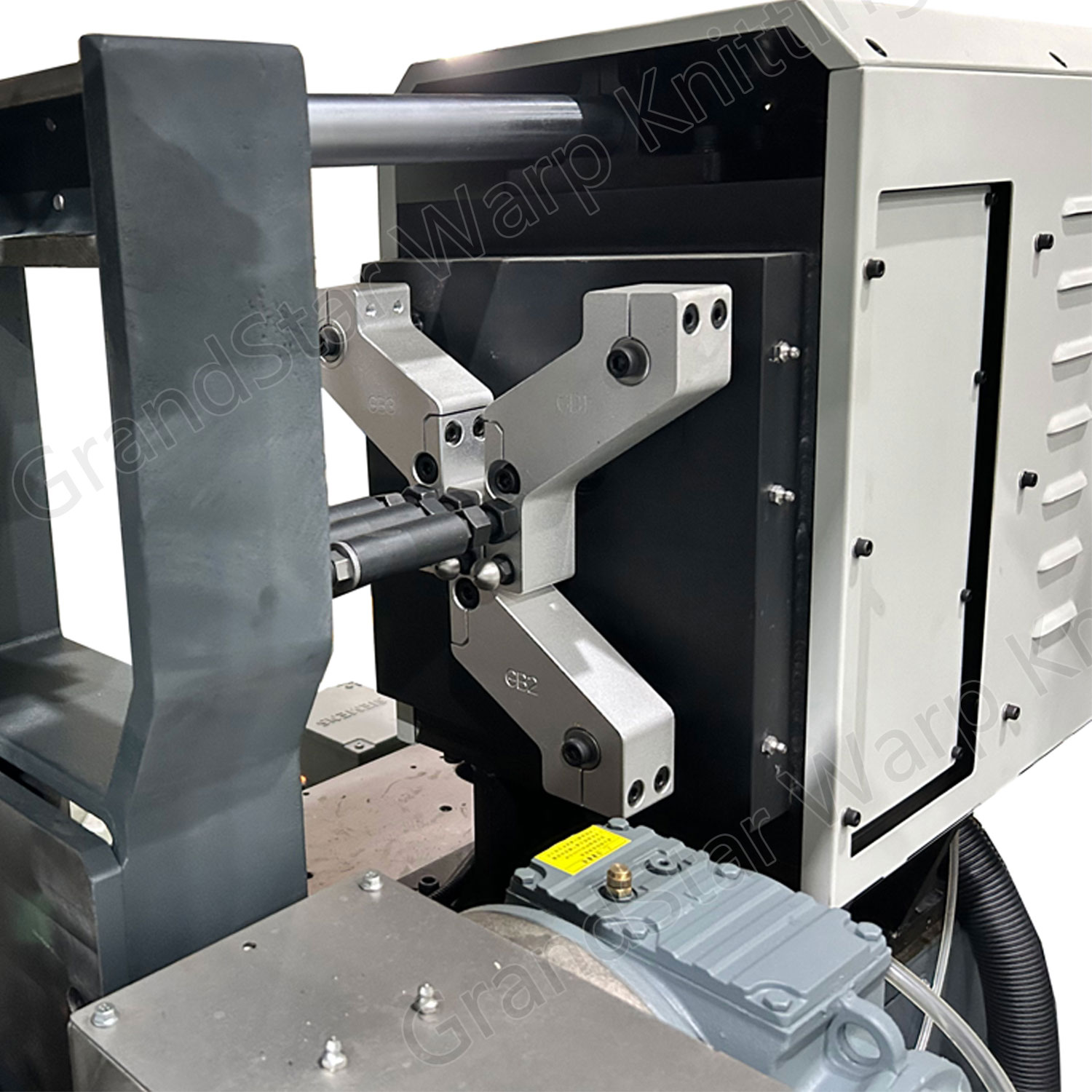

2. Industry-Leading Positioning Accuracy

With a precision exceeding 0.02mm, our EL system ensures ultra-precise needle movement. This translates to superior product consistency, enhanced pattern definition, and the ability to meet the most demanding quality standards in technical textiles and apparel.

3. Universal File Compatibility for Maximum Flexibility

Our EL system offers broad file compatibility, supporting industry-standard formats including:

- .KMO

- .MC

- .DEF

- .TXT

- .BMP

- .SZC

Additionally, each process file can support over 80,000 lines, providing manufacturers with exceptional flexibility to implement complex patterns, long-running programs, and intricate design variations without limitation.

4. Future-Ready Data Storage & Secure Access

GrandStar EL systems utilize reliable USB storage, while offering optional cloud-based storage and advanced access control technologies. This enables secure, scalable data management and ensures seamless integration with modern smart factory environments.

5. EL Retrofit Solutions — Upgrade Legacy Machines with Next-Generation Control

Our expertise extends beyond new equipment. GrandStar provides specialized retrofit solutions to upgrade aging warp knitting machines by replacing traditional pattern disks with our state-of-the-art EL system. This cost-effective modernization breathes new life into older machines, enhancing performance, expanding capabilities, and extending operational lifespan — without requiring complete machine replacement.

The GrandStar Advantage

- Global Leadership: Over 15 years of EL system development with worldwide customer success

- Unmatched Innovation: Continuous servo motor enhancements for faster response and greater load capacity

- Total Compatibility: Seamlessly integrates with both GrandStar and other major warp knitting machine brands

- Future-Proof Design: Supports evolving production needs with scalable, secure, and precise EL technology

Empower Your Production with the World’s Leading Warp Knitting EL System.

Contact GrandStar today to discover how our cutting-edge EL solutions can redefine your production performance.

CONTACT US

CONTACT US