Forged Shaft End For Warp Beam Support of Warp Knitting Machine

Forged Shaft End for Warp Beam Support

Precision Beam Locking for High-Speed Warp Knitting Production

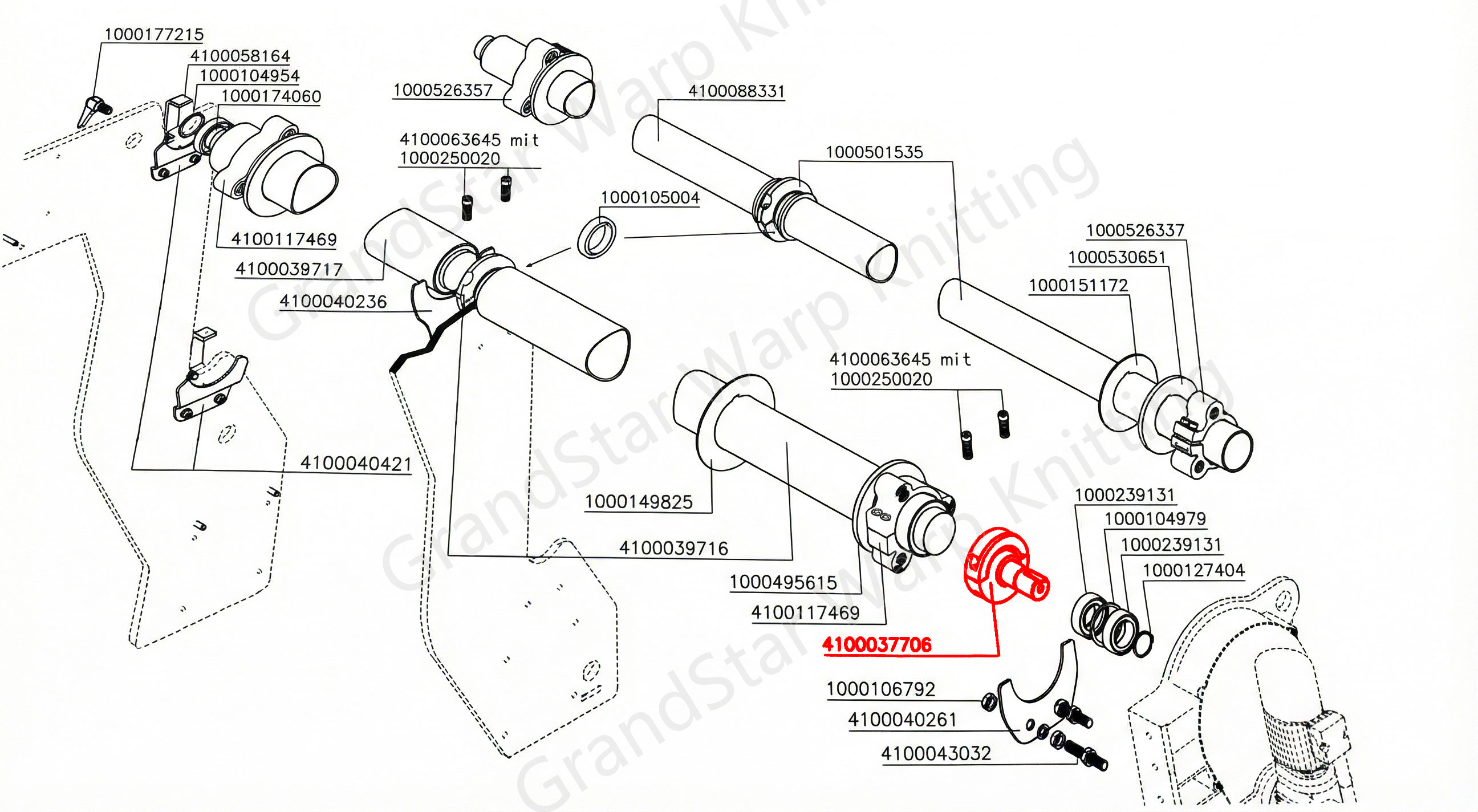

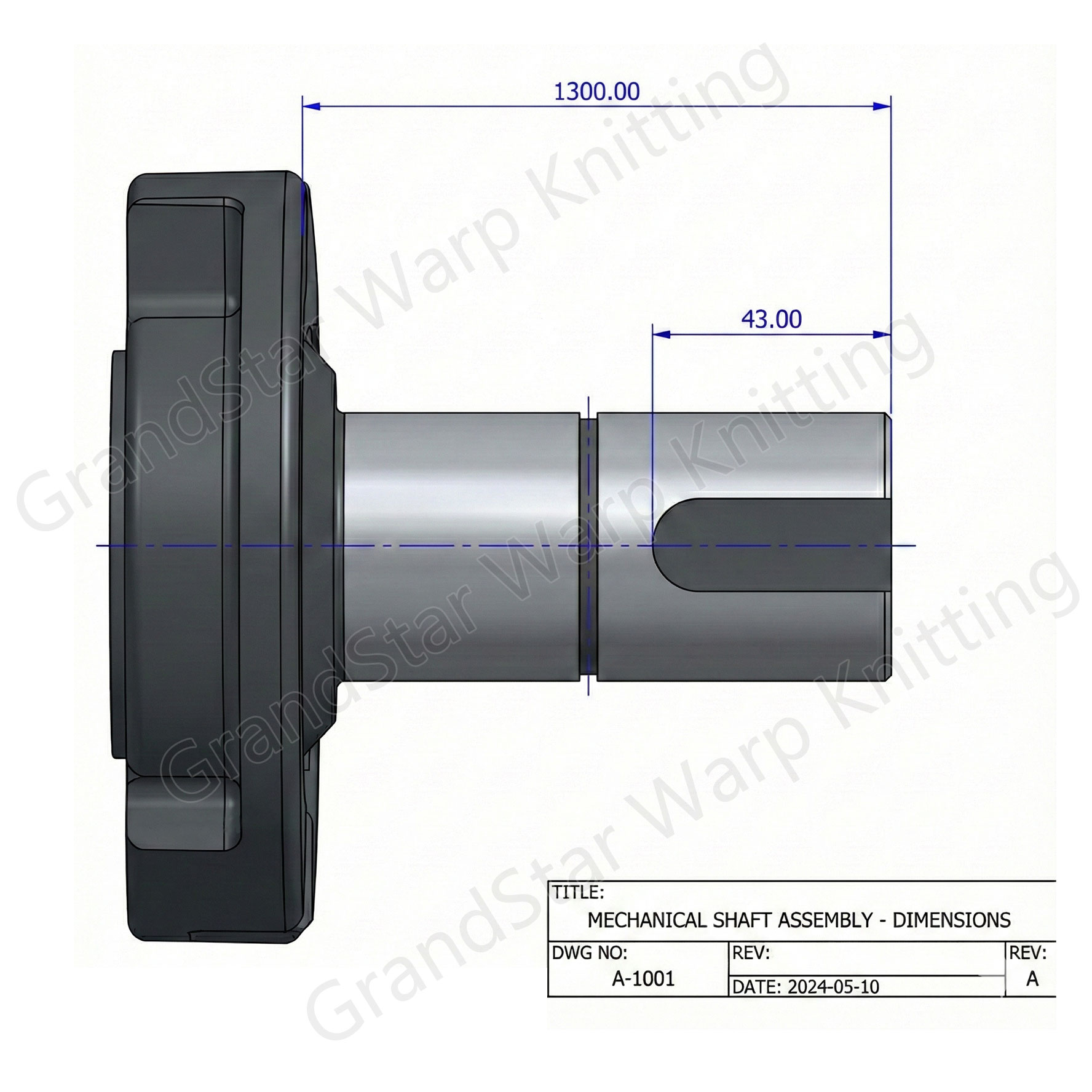

The Forged Shaft End for Warp Beam Support is a critical load-bearing component engineered for professional warp-knitting operations. Designed for Tricot, Double Needle Bar, and Raschel machines, it delivers stable beam alignment, rapid changeover, and long-term dimensional accuracy for high-output mills running at sustained speeds.

Manufactured from forged high-strength alloy steel and finished with precision CNC machining, this shaft end functions as a universal locking mechanism that minimizes beam slippage, preserves accurate alignment, and supports consistent warp tension across the full production cycle.

Best-fit keyword intent: forged shaft end, warp beam support, quick-lock beam change, CNC machined shaft end, D45 shaft end, tricot machine spare parts, raschel machine beam support, double needle bar machine components.

Why Forged Makes the Difference

Unlike cast or low-grade machined alternatives, a forged structure aligns metal grain flow along the load path. This improves fatigue resistance, increases torsional strength, and maintains stable performance under continuous full-load operation—especially important for high-speed warp knitting machines.

- Reduced micro-deformation under high warp tension

- Improved locking stability during long production runs

- Consistent concentricity for accurate beam rotation and smoother running

The result is practical, measurable value: cleaner fabric quality, fewer stops, and lower maintenance costs over the component life cycle.

Key Technical Advantages

Competitive Edge vs Conventional Shaft Ends

Compared with standard cast parts and low-grade shaft ends, this forged solution is built for high-speed, high-tension conditions and frequent start-stop cycles. It helps mills protect fabric quality while improving uptime.

- Longer service life under continuous production load

- Lower slippage risk to support stable warp tension and alignment

- Better concentricity to reduce defects and improve running smoothness

- Faster changeover to improve overall equipment efficiency (OEE)

For premium fabrics, wide machines, or heavy beams, these advantages directly support stable production output and consistent fabric appearance.

Ideal Applications

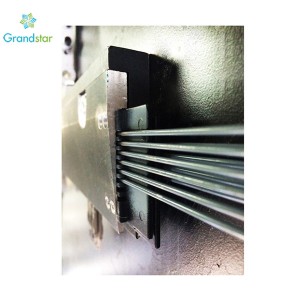

- High-speed tricot fabric production

- Double needle bar technical textiles

- Raschel netting, lace, and spacer fabrics

- Machine refurbishment and performance upgrades

A Small Component with Major Impact

In warp knitting, beam stability affects fabric quality and machine reliability. The Forged Shaft End for Warp Beam Support is engineered for professional mills that require strength, precision fit, and long-term reliability—supporting stable production standards at scale.

Request a Quote / Technical Confirmation

To confirm the correct fit, please share your machine model, beam specification, and any photos or drawings of the existing shaft end. Our team will recommend the best configuration for your production line.

CONTACT US

CONTACT US