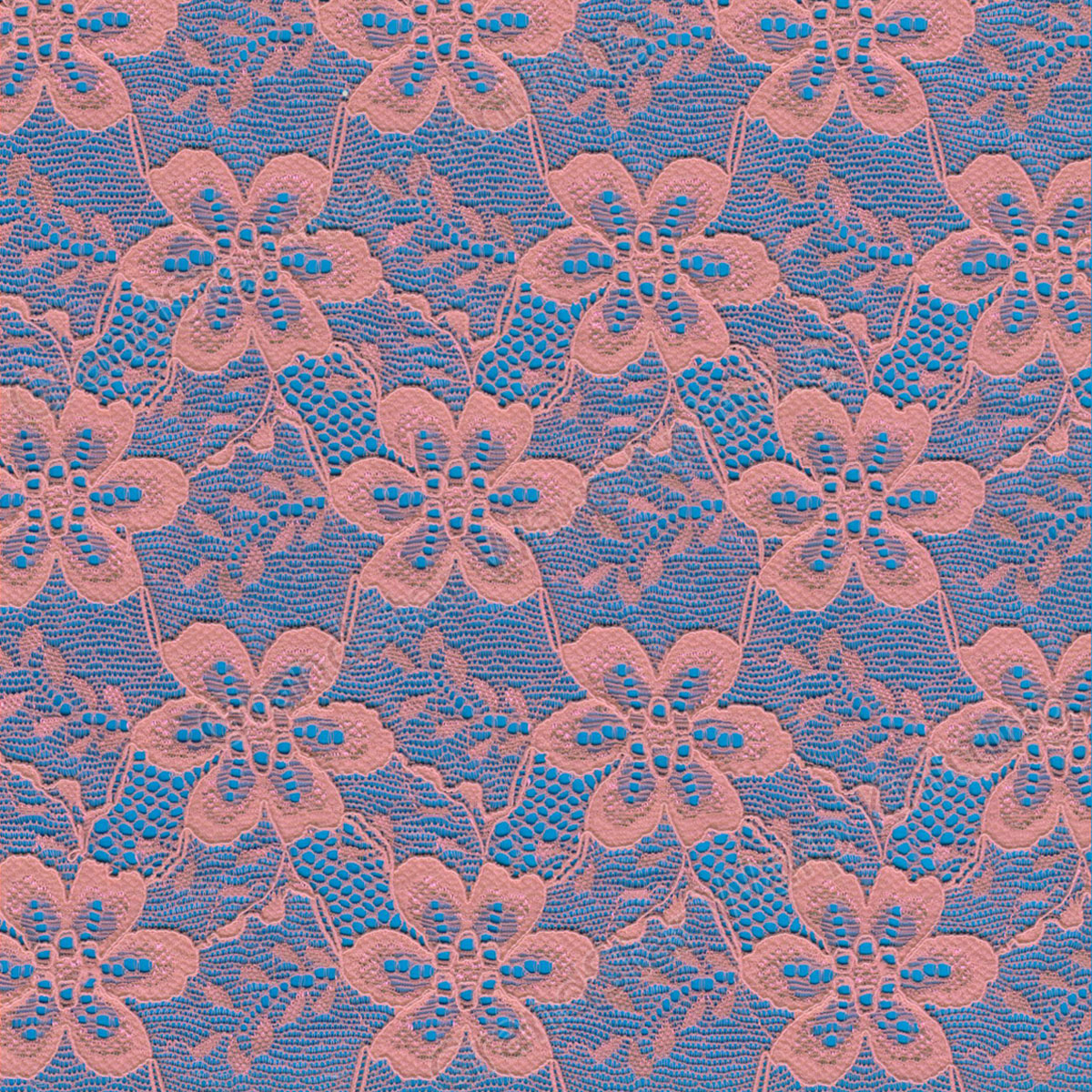

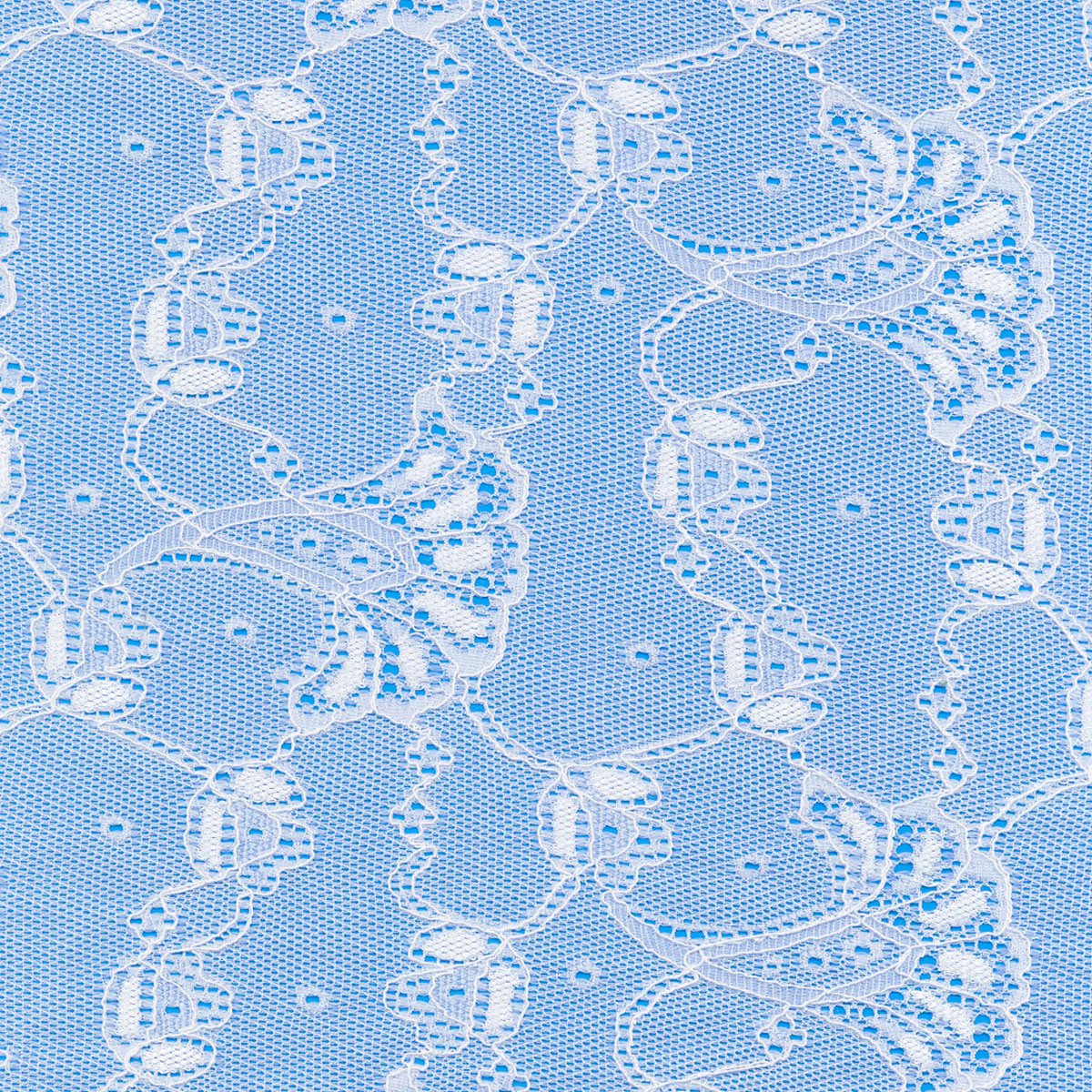

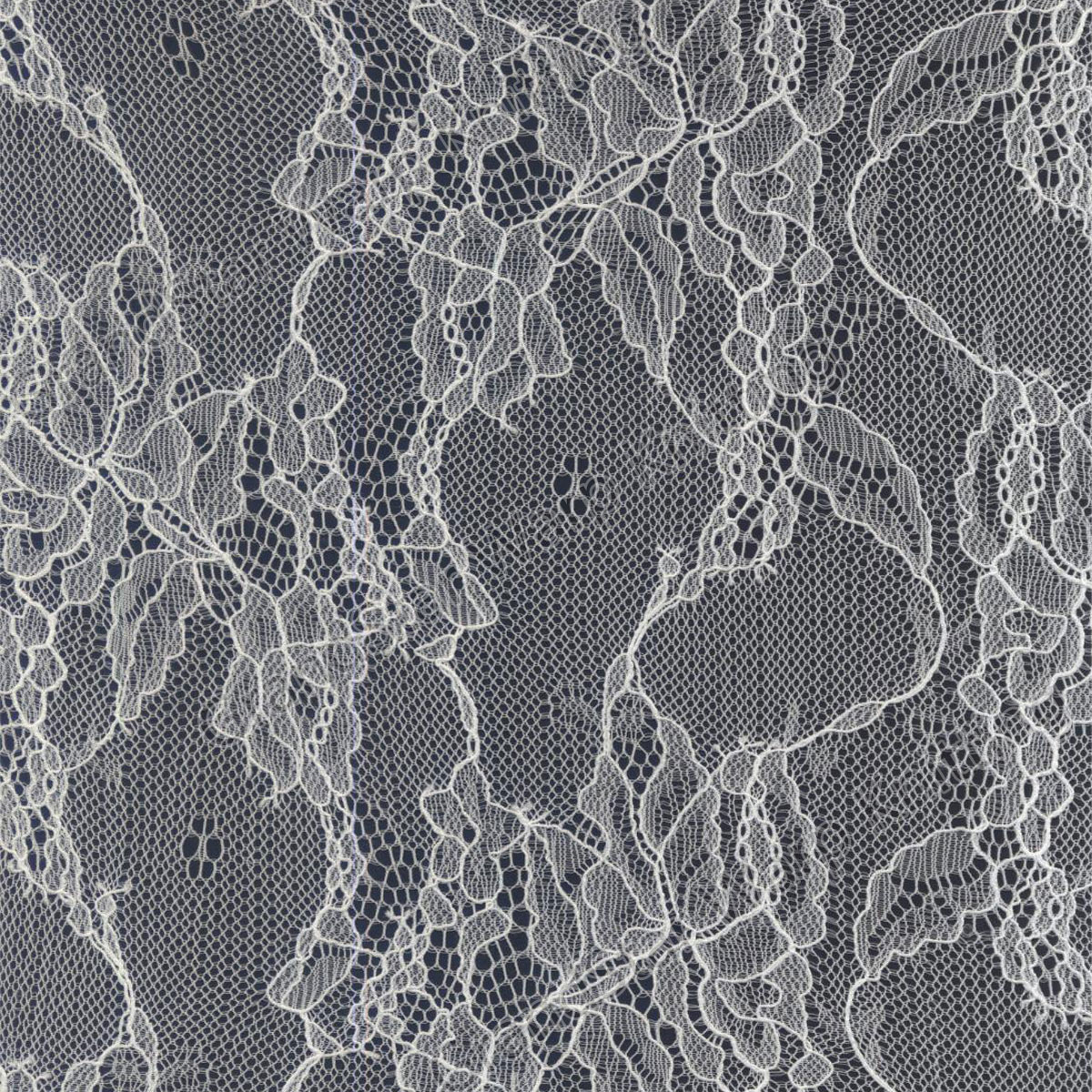

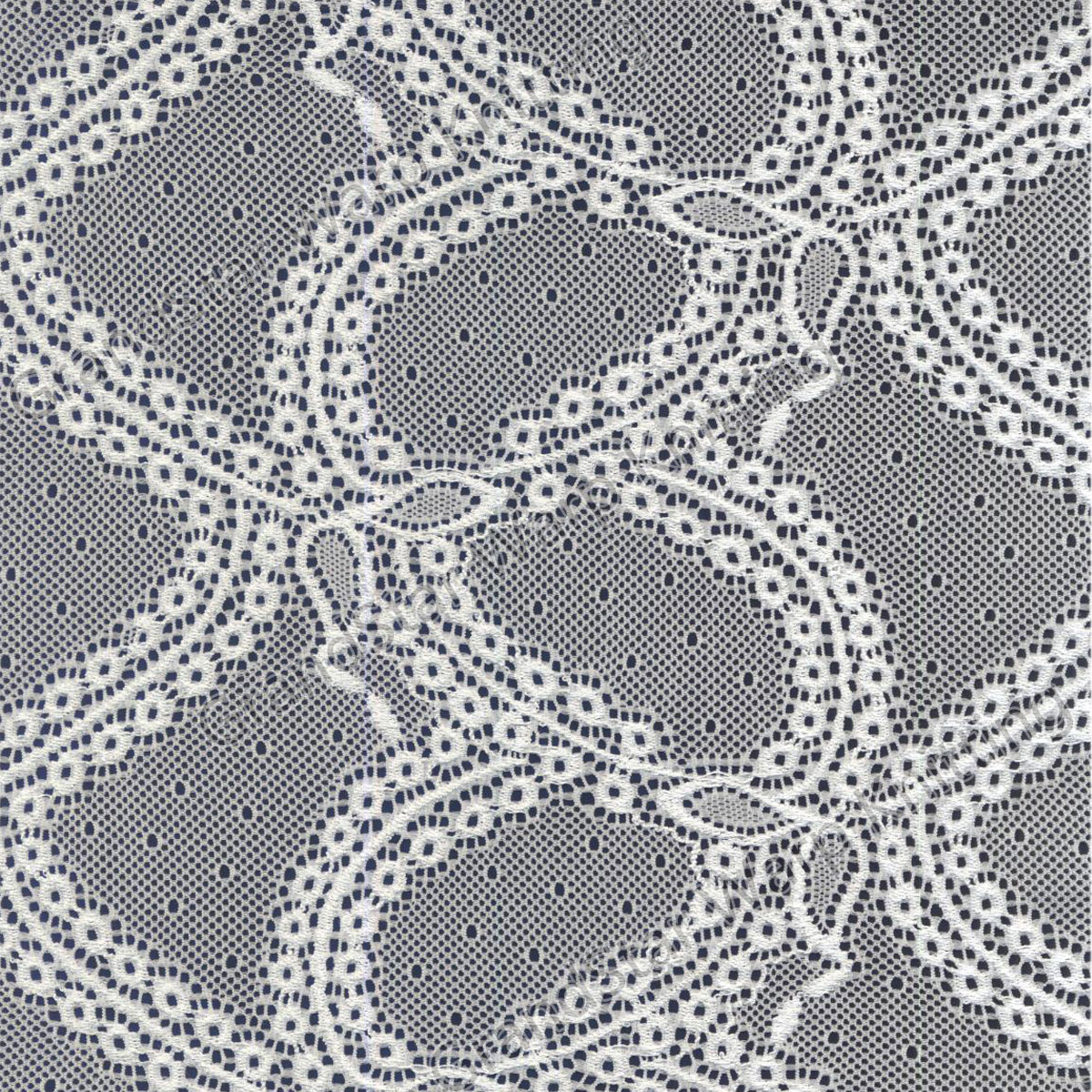

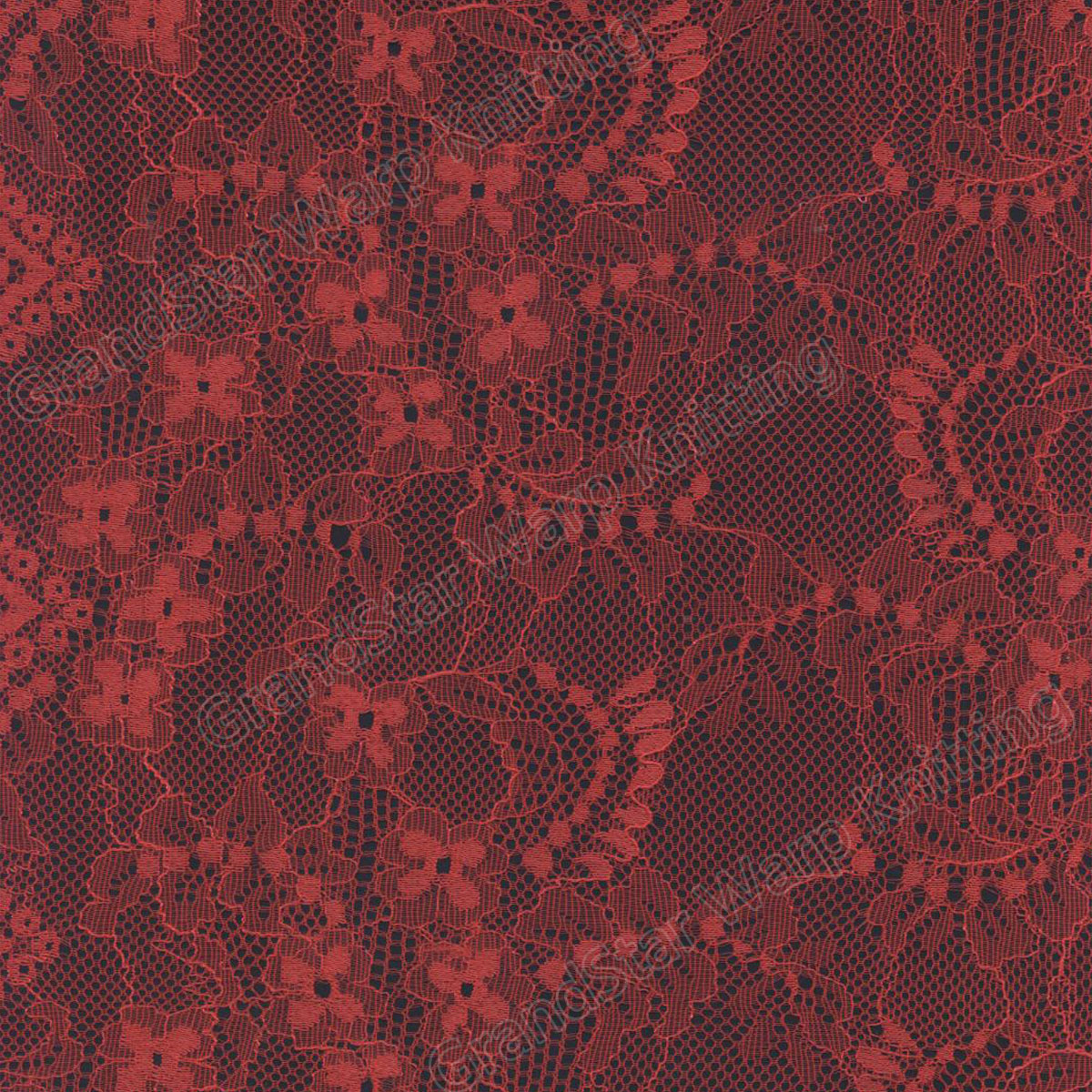

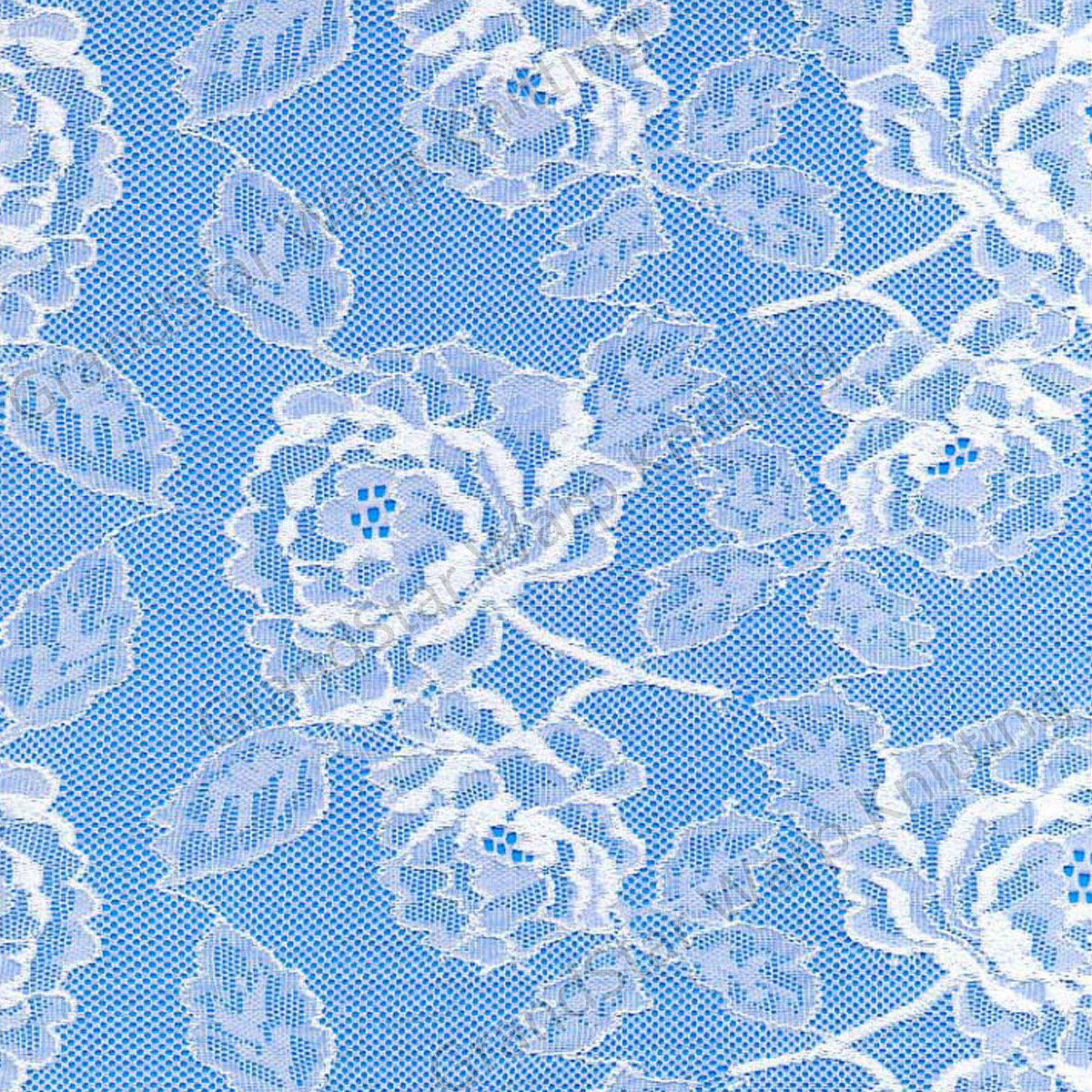

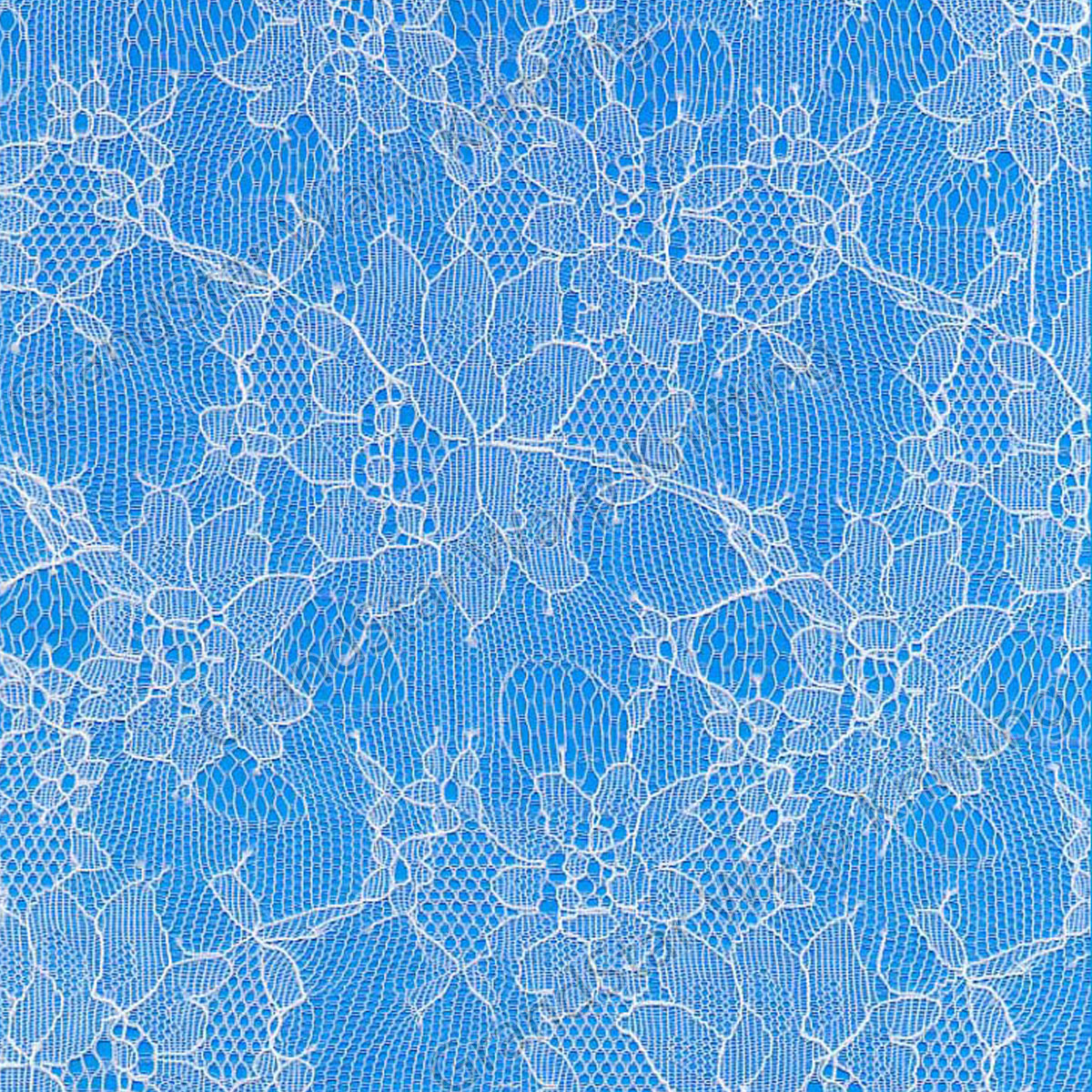

Jacquard Lace Versatility

All fabrics displayed on this page are produced on GrandStar’s Jacquard Multi-Bar Lace Warp Knitting Machines, engineered specifically for high-precision lace production. These machines combine stable mechanical design with multi-bar patterning and piezo-jacquard control to meet the demanding requirements of modern lace manufacturing.

Advanced Jacquard Lace Production Platform

GrandStar’s Jacquard Multi-Bar Raschel Lace Warp Knitting Machines are designed for producing high-quality patterned lace fabrics, ranging from delicate trims to sophisticated all-over structures. By integrating multi-guide-bar technology with piezo-jacquard systems, the machines provide precise control of yarn movement, pattern definition, and fabric geometry. The result is a flexible production platform that delivers both intricate design detail and consistent industrial performance.

Wide Fabric Spectrum and Structural Flexibility

A key advantage of GrandStar’s multi-bar jacquard lace machines is their ability to produce a broad spectrum of lace fabrics with different structures, densities, and visual effects. Depending on machine configuration, pattern bar quantity, and jacquard bar positioning, manufacturers can produce:

- Patterned lace trims with fine edges and sharp motif definition

- Lace galloons for decorative and functional garment components

- All-over lace fabrics with stable ground structures

- Rigid or semi-rigid lace suitable for ladies’ outerwear and structured garments

- Soft, delicate lace optimized for intimate apparel and lingerie

Multiple pattern bars enable complex overlapping motifs, layered textures, and rich visual effects, giving designers greater creative freedom while maintaining production efficiency.

Configurable Machine Models for Diverse Applications

GrandStar offers a comprehensive range of multi-bar jacquard raschel lace machine models, typically classified by:

- Number of pattern guide bars

- Jacquard control specification and quantity

- Working position of piezo-jacquard bars

This modular approach helps manufacturers match machine configuration to target fabric requirements—whether producing lightweight lingerie lace or more rigid lace structures for ladies’ outerwear—while supporting efficient product diversification and strong return on investment.

Premium Applications Across Fashion Segments

Fabrics produced on GrandStar’s Jacquard Multi-Bar Lace Warp Knitting Machines are widely used across high-value fashion and apparel sectors, including:

- Lingerie and intimate apparel, where softness and refined pattern detail are essential

- Ladies’ outerwear, requiring dimensional stability and durable lace structures

- Decorative lace trims and galloons, used for garment edges, inserts, and ornamental elements

Precision, Quality, and Design Freedom

By combining stable mechanical construction with advanced jacquard technology, GrandStar lace machines help ensure high pattern accuracy, clean motif definition, and consistent fabric quality across long production runs. This supports the production of luxurious lace fabrics aligned with global market expectations.

A Strategic Choice for Lace Manufacturers

With strong versatility, configurable models, and a proven fabric range, GrandStar’s Jacquard Multi-Bar Raschel Lace Warp Knitting Machines provide a future-ready solution for lace producers aiming to expand design possibilities, improve product quality, and respond quickly to changing market demands—from fine lingerie lace to structured outerwear fabrics.

CONTACT US

CONTACT US