RS 2(3) Netting Warp Knitting Machine

Single-Bar Raschel Machines: Iyo Ideal Solution yeNet Production

Single-bar Raschel michina inopa inovamba uye inoshanda zvakanyanya mhinduro yekugadzira akasiyana mambure emachira, anosanganisira ekurima, kuchengetedza,

nemambure okuredza. Aya mambure anoshanda zvakasiyana-siyana zvekushandisa, nerimwe remabasa awo ekutanga kuve dziviriro kubva kune yakashata mamiriro ekunze. In

zviitiko izvi, zvinofanirwa kushingirira kutarisana nemamiriro ekunze akasiyana. Iyo yepamusoro warp knitting tekinoroji yakabatanidzwa mune imwe-bhara Raschel

michina inopa isingaenzaniswi mikana yekugadzira mambure, inodarika chero imwe nzira yekugadzira mukuita zvakasiyana uye kuita.

Zvinhu Zvikuru Zvinokurudzira Hunhu hweNet

- Lapping technique

- Nhamba yemabhawa ekutungamira

- Machine gauge

- Kurongeka kweshinda

- Stitch density

- Rudzi rweshinda yakashandiswa

Nekugadzirisa aya ma paramita, vagadziri vanogona kugadzirisa zvivakwa zvemambure kuti asangane nezvinodiwa zvakasiyana-siyana zvekushandisa, senge:

- Zuva rekudzivirira chinhu:Kudzora mwero wemumvuri wakapihwa

- Mhepo permeability:Kugadzirisa kuramba kwemhepo

- Opacity:Kugadzirisa kuoneka kuburikidza nemambure

- Kugadzikana uye elasticity:Kugadzirisa kuchinjika mukureba uye kuyambuka nzira

Yakakosha Lapping Zvivakwa zveNet Production

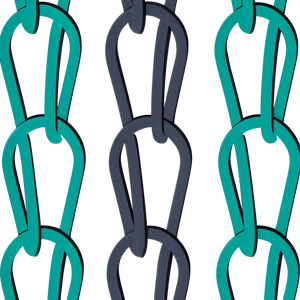

1. Mbiru Musono

Thembiru musono kuvakandiyo hwaro hwekugadzira mambure uye ndiyo inonyanya kushandiswa nzira yekupeta. Inosimbisa iyo

zvinodiwakureba simba uye kugadzikana, zvichiita kuti ive yakakosha pakusimba kwemambure. Nekudaro, kugadzira inoshanda textile substrate,

musono wembiru unofanirwa kusanganiswa neinlay lappingkana zvimwe zvivako zvinopindirana.

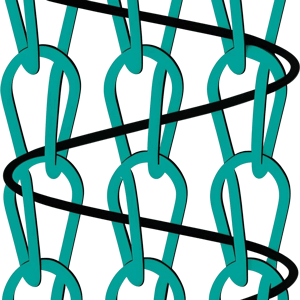

2. Inlay (Weft)

Nepo aninlay chimirochete haigone kuumba textile substrate, inoita basa rakakosha mukaticrosswise kugadzikana. By

kubatanidza maviri, matatu, kana kupfuura ma-stitch wales, iyo inlay inosimudzira kuramba kwejira kune lateral masimba. Kazhinji, kuwanda kwewales kwakabatana

pamwe chete muchiuno, zvakanyanyayakagadzikana uye yakagadzikanamambure anova.

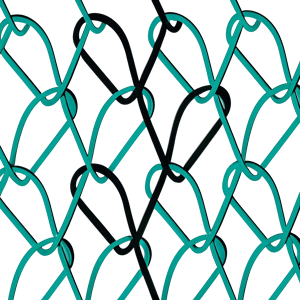

3. Tricot Lapping

Tricot lapping inowanikwa nekudivi shoggingchemuperekedzi bhaa maererano netsono iri pedyo. Kana yakashandiswa pasina kuwedzera

dhairekitori mabhawa, zvinoguma mune yakanyanyaelastic jira. Nekuda kwehunhu hwayoyakakwirira elasticitymukureba uye

kuyambuka nzira, tricot lapping haiwanzo kushandiswa mukugadzira mambure-kunze kwekunge yasanganiswa nemamwe mabhawa ekutungamira kuti uvandudze kugadzikana.

4. 2 x 1 Lapping

Zvakafanana netricot lapping, iyo2 x 1 kupetainobatana neadjacent wales. Nekudaro, pachinzvimbo chekugadzira chinotevera loop pane nekukurumidza

tsono iri pedyo, inogadzirwa pane inotevera-asi-imwe tsono. Iyi nheyo inoshanda kune akawanda anosona lappings, kunze kwepillar stitch

kuvaka.

Kugadzira Mambure ane Maumbirwo akasiyana uye saizi

Chinhu chakakosha pakugadzira mambure ndiko kugona kugadzira mambure ekuvhura mukatihukuru hwakasiyana uye maumbirwo, iyo inowanikwa nekugadzirisa kiyi

zvinhu zvakadai se:

- Machinegauge

- Lapping kugadzira

- Stitch density

Mukuwedzera, iyokugadzirwa kweshindainoita basa guru. Kusiyana neyakajairwa magadzirirwo, iyo tambo yekushongedza haisi nguva dzose

inofanirwa kuenderana zvakakwana negeji yemuchina. Kuti uwedzere kuchinjika, kupinza misiyano senge1 mukati, 1 kunze or

1 mukati, 2 kunzeanoshandiswa kazhinji. Izvi zvinobvumira vagadziri kugadzira akasiyana siyana emambure pamushini mumwe chete, kuderedza nguva yekudzikira

uye kubvisa kudiwa kwekuchinja nguva nenguva, kunopedza nguva.

Mhedziso: Kunyanya Kubudirira neWarp Knitting Technology

Single-bar Raschel michina inopakunyatsoshanda uye kuchinjikayekugadzira machira mambure, kuve nechokwadi chemhando yepamusoro mukati

simba, kugadzikana, uye kugadzira zvakasiyana-siyana. Nekushandisa advanced warp knitting tekinoroji, vagadziri vanogona kugadzirisa mambure zvivakwa kuti vasangane

huwandu hwakakura hwemaindasitiri uye edziviriro maapplication - kuseta mabhenji matsva mukunaka kwekugadzira mambure.

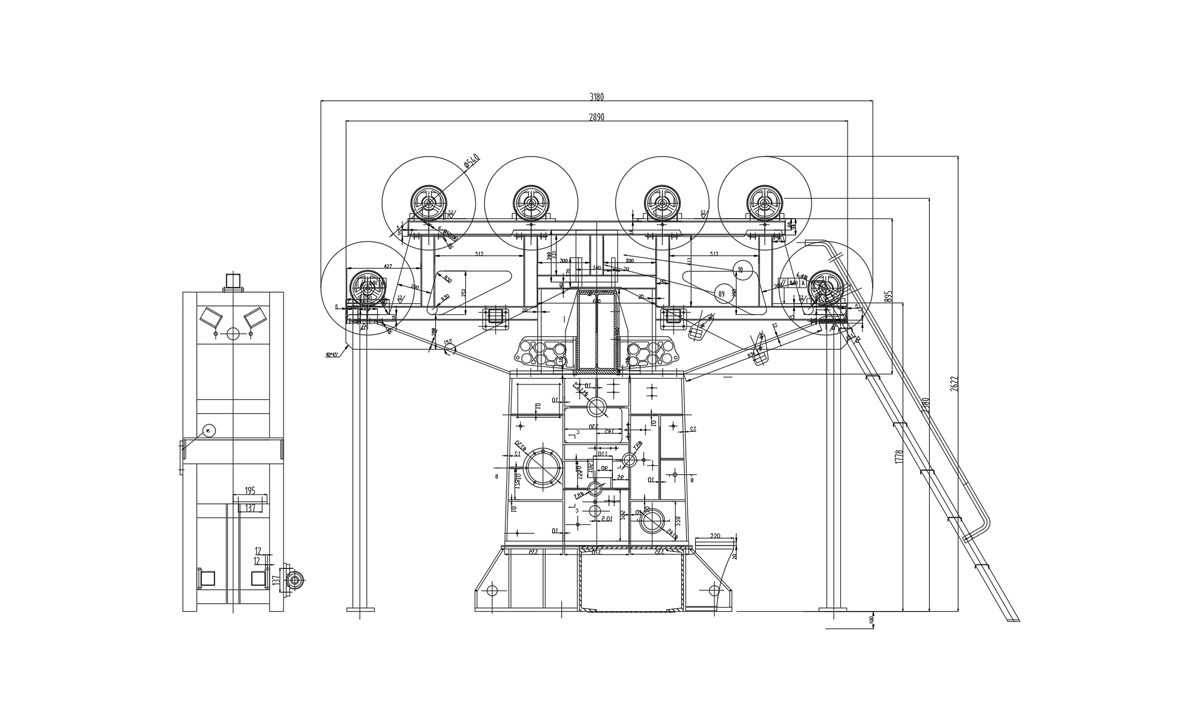

GrandStar® Warp Knitting Machine Specifications

Working Width Options:

- 4597mm (181″)

- 5207mm (205″)

- 6807mm (268″)

- 7188mm (283″)

- 8509mm (335″)

- 10490mm (413 ″)

- 12776mm (503 ″)

Gauge Sarudzo:

- E2, E3, E4, E5, E6, E8

Knitting Elements:

- Needle Bar:1 imwe tsono bar inoshandisa latch tsono.

- Slider Bar:1 slider bar ine ndiro inotsvedza mayunitsi.

- Knockover Bar:1 kugogodza pamusoro pecomb bar ine knock-over units.

- Mabhawa ekutungamirira:2(3) mabhawa ekutungamira ane precision-engineered guide units.

- Material:magnalium mabara esimba repamusoro uye kuderedzwa kwekudedera.

Yarn Feeding System:

- Warp Beam Support:2(3) × 812mm (32″) (yakasununguka-yakamira)

- Yarn Feeding Creel:Kushanda kubva kucreel

- FTL:Firimu Kucheka uye strctching mudziyo

GrandStar® Control System:

TheGrandStar COMMAND SYSTEMinopa intuitive opareta interface, inobvumira isina musono gadziriso yemuchina uye chaiyo yemagetsi basa rekutonga.

Integrated Monitoring Systems:

- Yakabatanidzwa Laserstop:Yepamberi chaiyo-nguva yekutarisa system.

Yarn Let-Off System:

Imwe neimwe warp beam chinzvimbo inoratidzira antambo inodzorwa nemagetsi let-off drivekuitira kunyatsogadzirisa tension.

Fabric Take-Up Mechanism:

Akashongedzerwa neelectronically regulated fabric take-up systeminotyairwa neicho chepamusoro-chaiyo mota.

Batching Device:

A patsanura pasi-yakamira jira rekukungurutsa mudziyoinovimbisa kutsetseka kwejira remachira.

Pattern Drive System:

- Standard:N-drive ine matatu pateni discs uye yakabatanidzwa tempi shanduko giya.

- Sarudzo:EL-kutyaira ine mota dzinodzorwa nemagetsi, ichibvumira mabara ekutungamira kuti asvike pa50mm (inosarudzika yekuwedzera kusvika 80mm).

Zvemagetsi Zvinodiwa:

- Drive System:Speed inodzorwa dhiraivha ine yakazara yakabatana mutoro we25 kVA.

- Voltage:380V ± 10%, matatu-chikamu simba rekupa.

- Main Power Cord:Minimum 4mm² matatu-chikamu mana-core tambo, pasi waya isingasviki 6mm².

Oiri Supply System:

Advancedmafuta / mvura kupisa exchangerinovimbisa kushanda kwakakwana.

Operating Environment:

- Tembiricha:25°C ± 6°C

- Humidity:65% ± 10%

- Floor Pressure:2000-4000 kg/m²

Huremu hwe polyethylene mambure akagadzirirwa kuchengetedza uswa uye mabhero ehuswa, pamwe nekudzikamisa mapallets ekutakura. Yakagadzirwa nehunyanzvi hwepillar stitch / inlay tekinoroji, mambure aya anoratidza zvakaparadzana wales uye yakaderera density yetsono kuitira kunyatsoita. Iyo batching sisitimu inovimbisa zvakasimba kudzvanywa ma rolls ane kureba kwekumhanya, kuwedzera kugona uye kuchengetedza.

Inoshandiswa zvakanyanya mumamiriro ekunze anodziya, mambure e-warp-knitted shade anodzivirira zvirimwa uye greenhouses kubva kune yakanyanya zuva, kudzivirira kupera mvura uye kuve nechokwadi chekukura kwemamiriro ezvinhu. Ivo zvakare vanosimudzira kutenderera kwemhepo, kuderedza kupisa kuvaka kune imwe nzvimbo yakagadzikana.

Kudzivirira MvuraMuchina wega wega wakavharwa zvine hungwaru nekurongedza kwakachengeteka kwegungwa, uchipa dziviriro yakasimba kubva mukunyoro uye kukuvadzwa kwemvura mukati mekufamba. | International Export-Standard Wooden NyayaYedu-yakasimba-yakasimba inoumbwa makesi emapuranga anoenderana zvizere nemitemo yepasirese kunze kwenyika, kuve nechokwadi chekuchengetedzwa kwakanyanya uye kugadzikana panguva yekufambisa. | Inoshanda & Yakavimbika LogisticsKubva pakubata zvine hungwaru panzvimbo yedu kusvika kune nyanzvi yekurodha mudziyo pachiteshi, nhanho yega yega yehurongwa hwekutumira inodzorwa nemazvo kuvimbisa kuchengetedzwa uye nenguva. |

TAURA NESU

TAURA NESU