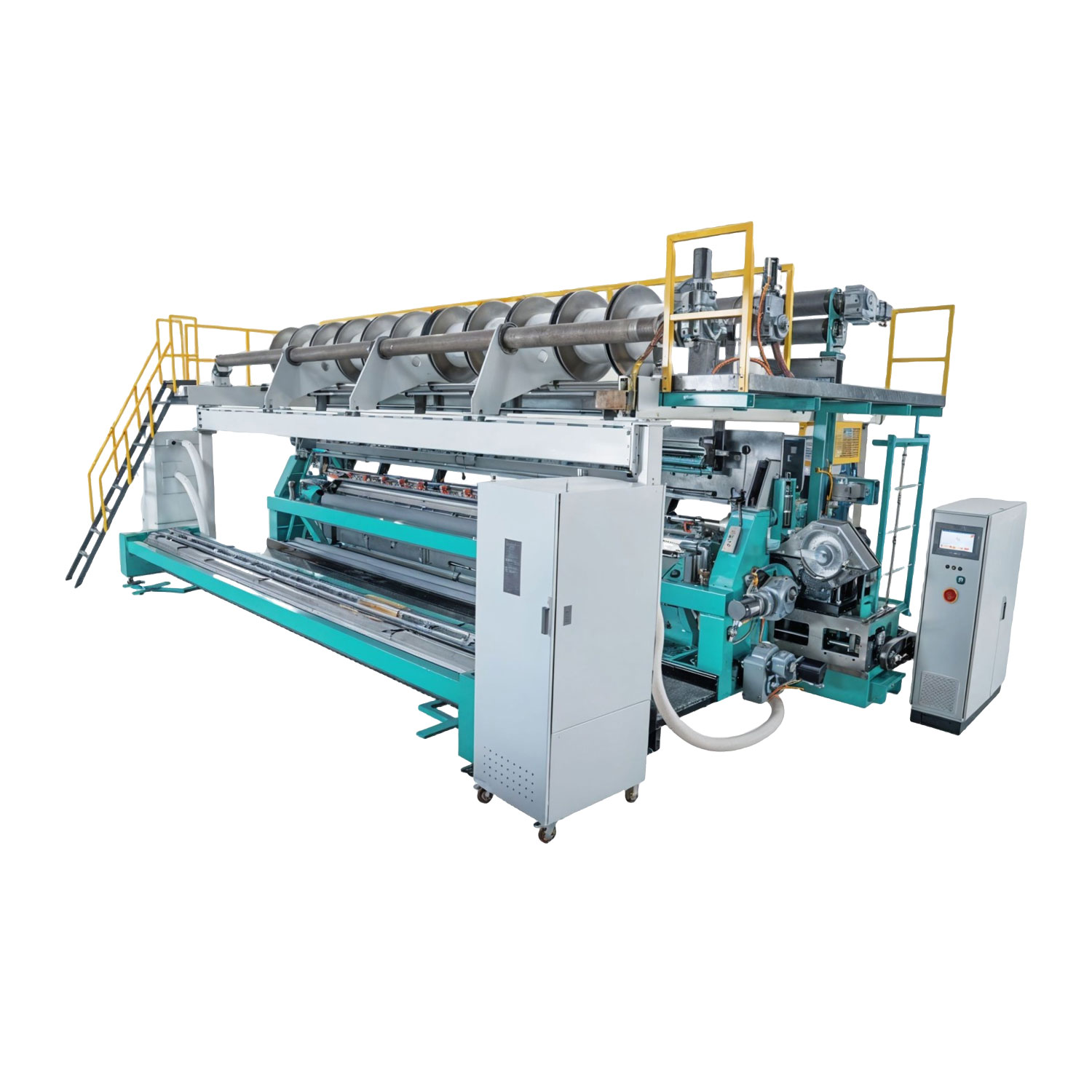

HKS2-MSUS 2 Bhara Tricot Ine Weft-kuisa

HKS Weft-Insertion Machina eMicheka Yakareruka

Unleashing Innovation muWarp Knitting

TheHKS weft-insertion muchinandeyepamusoro, inoshanda-yepamusoro warp knitting mhinduro yakagadzirirwa kusangana nekuomarara kwezvinodiwa zvemazuva ano kugadzira micheka. Engineered with acourse-oriented weft-insertion system, inopa husingaenzaniswi hunobudirira uye huchokwadi mukugadzira machira akareruka kune akasiyana siyana ekushandisa.

Zvishandiso Zvakasiyana-siyana MumaIndustries

YeduHKS weft-insertion muchinayakagadzirwa nehunyanzvi kuti ienderane nezvinodiwa nemaindasitiri akawanda, ichipa kusarudzika kwakasiyana-siyana mukugadzira machira. Kunyangwe kusimudzira machira anoshanda kana zvinhu zvekushongedza, muchina uyu unobatanidza zvisina mutsetse mune akasiyana maapplication:

- Embroidery Grounds & Tulle-Inoburitsa yakanaka, yakaoma machira magadzirirwo akanakira embroidery uye lace application.

- Interlinings-Inogadzira yakagadzikana uye yakasimba interlining zvinhu zvakakosha pakusimbisa nguo.

- Medical Textiles- Inogonesa kugadzirwa kwemachira emhando yepamusorohemodialysis filters uye oxygenators, kusangana nemitemo yakaoma yehutano.

- Outerwear Fabrics-Inopa machira akareruka asi akasimba anokodzera fashoni uye mapfekero ekuita.

- Coating Substrates & Advertising Media-Inotsigira kugadzirwa kweakasimba, anodhinda substrates ekushandiswa kwemaindasitiri nekutengesa.

Mabhenefiti Akasarudzika eKushanda Kwepamusoro

TheHKS weft-insertion muchinayakagadzirirwa kuunza kushanda kwepamusoro, kuve nechokwadi chekubuda kwepamusoro nekuderera kushoma nguva. Mabhenefiti akakosha anosanganisira:

- Kubudirira Kwepamusoro-Optimized muchina dynamics inogonesa kukurumidza kukurumidza kugadzira, kuwedzera kuburitsa pasina kukanganisa kunaka.

- Wide Application Variety-Inokwanisa kugadzirisa zvakasiyana-siyana maumbirwo efiber uye machira ekuvaka, kuve nechokwadi chekuchinjika mukugadzirwa.

- Carbon Bar Technology-Inowanikwa nekabhoni mabara ekusimudzira kugadzikana, kuve nechokwadi chekugadzirisa kunoenderana kunyangwe pasi petembiricha inochinja.

Simudza Kugona Kwako Kwekugadzira

Nechizvino-che-iyo-injiniya uye indasitiri inotungamira hunyanzvi, iyoHKS weft-insertion muchinandiyo sarudzo yakanakira vagadziri vanovavarira kugadzira emhando yepamusoro machira akareruka nekushanda uye nemazvo.

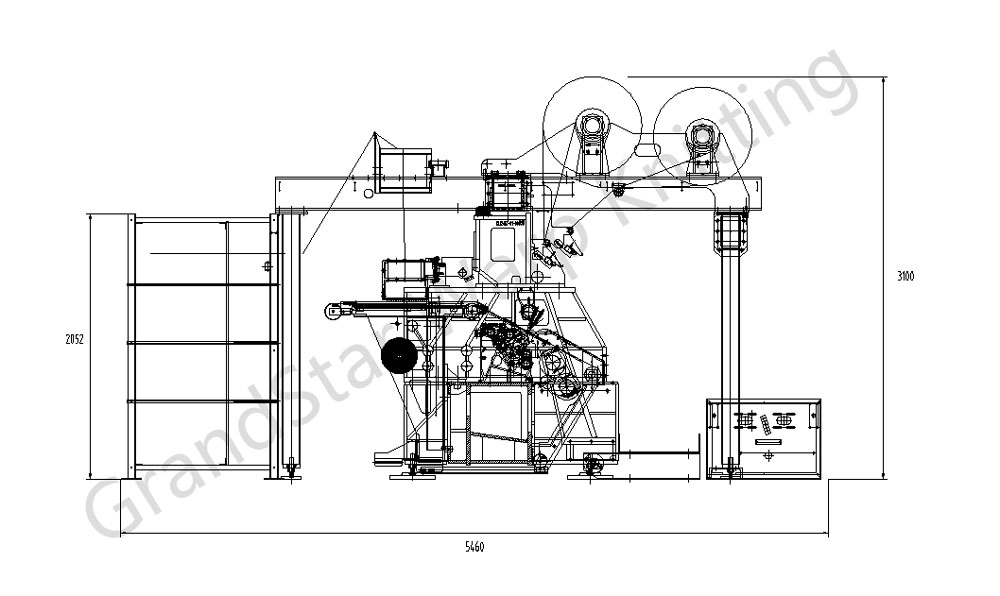

GrandStar® Warp Knitting Machine Specifications

Working Width Options:

- 3454mm (136″)

- 6223mm (245″)

Gauge Sarudzo:

- E24 E28

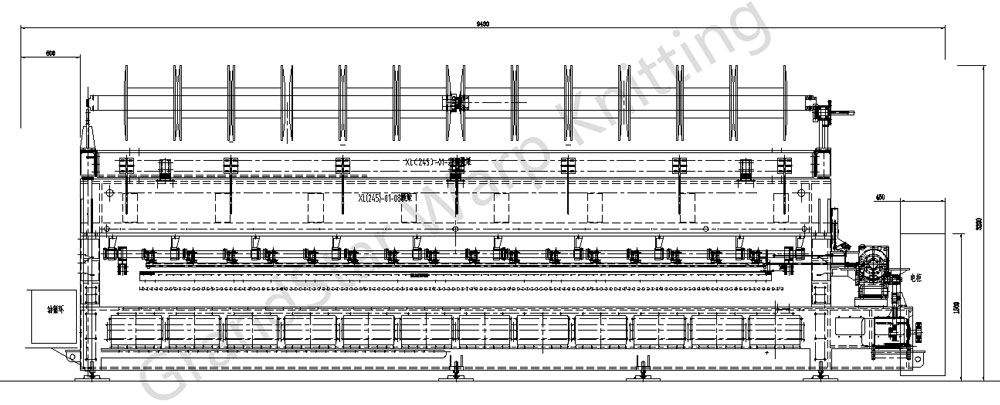

Knitting Elements:

- Needle Bar:1 bhaa yetsono inoshandisa tsono dzakasanganiswa.

- Slider Bar:1 slider bar ine ndiro inotsvedza zvikamu (1/2 ″).

- Sinker Bar:1 sinker bar ine makomisheni siker mayunitsi.

- Mabhawa ekutungamirira:2 giredhi mabara ane precision-engineered guide units.

- Material:Carbon-fiber-yakasimbiswa mabhawa ekusimba epamusoro uye yakaderedzwa vibration.

Warp Beam Support Configuration:

- Standard:2 × 812mm (32″)

- Sarudzo:

- 2 × 1016mm (40″) (yakasununguka-yakamira)

Weft-insertion system:

- Standard:Ngoro yekuisa shinda ine 24 magumo

GrandStar® Control System:

TheGrandStar COMMAND SYSTEMinopa intuitive opareta interface, inobvumira isina musono gadziriso yemuchina uye chaiyo yemagetsi basa rekutonga.

Integrated Monitoring Systems:

- Yakabatanidzwa Laserstop:Yepamberi chaiyo-nguva yekutarisa system.

- Sarudzo: Kamera System:Inopa chaiyo-nguva yekuona mhinduro yechokwadi.

Yarn Let-Off System:

Imwe neimwe warp beam chinzvimbo inoratidzira antambo inodzorwa nemagetsi let-off drivekuitira kunyatsogadzirisa tension.

Fabric Take-Up Mechanism:

Akashongedzerwa neelectronically regulated fabric take-up systeminotyairwa neicho chepamusoro-chaiyo mota.

Batching Device:

Batching system ine pamusoro pemhepo.

Pattern Drive System:

- Standard:N-drive ine matatu pateni discs uye yakabatanidzwa tempi shanduko giya.

- Sarudzo:EL-kutyaira ine mota dzinodzorwa nemagetsi, ichibvumira mabara ekutungamira kuti asvike pa50mm (inosarudzika yekuwedzera kusvika 80mm).

Zvemagetsi Zvinodiwa:

- Drive System:Speed inodzorwa dhiraivha ine yakazara yakabatana mutoro we25 kVA.

- Voltage:380V ± 10%, matatu-chikamu simba rekupa.

- Main Power Cord:Minimum 4mm² matatu-chikamu mana-core tambo, pasi waya isingasviki 6mm².

Oiri Supply System:

Advancedmafuta / mvura kupisa exchangerinovimbisa kushanda kwakakwana.

Operating Environment:

- Tembiricha:25°C ± 6°C

- Humidity:65% ± 10%

- Floor Pressure:2000-4000 kg/m²

Crinkle warp knitting jira isarudzo ine mukurumbira pakati pemafashoni makuru ekukurumidza uye emhando yepamusoro senge Uniqlo, Zara, uye HM. Michina yedu yekuruka yewarp, kunyanya iyo Weft Insertion Machine, inoshandiswa kugadzira jira iri rakashongedzwa, rakagadzirwa, richisangana nemhando yepamusoro yedhizaini.

Iri jira reketeni rinosanganisa Lurex-yakabatanidzwa shinda yakaoma ine pasi-yakagomara pasi, ichigadzira inoyevedza simbi inotaridzika. Inoramba iine chiedza chinooneka nekuda kwechimiro chayo chakajeka asi chakagadzikana. Kugara kwayo muhurefu nehupamhi kunoita kuti ive yakanaka kune embroidery application zvakare.

Kudzivirira MvuraMuchina wega wega wakavharwa zvine hungwaru nekurongedza kwakachengeteka kwegungwa, uchipa dziviriro yakasimba kubva mukunyoro uye kukuvadzwa kwemvura mukati mekufamba. | International Export-Standard Wooden NyayaYedu-yakasimba-yakasimba inoumbwa makesi emapuranga anoenderana zvizere nemitemo yepasirese kunze kwenyika, kuve nechokwadi chekuchengetedzwa kwakanyanya uye kugadzikana panguva yekufambisa. | Inoshanda & Yakavimbika LogisticsKubva pakubata zvine hungwaru panzvimbo yedu kusvika kune nyanzvi yekurodha mudziyo pachiteshi, nhanho yega yega yehurongwa hwekutumira inodzorwa nemazvo kuvimbisa kuchengetedzwa uye nenguva. |

TAURA NESU

TAURA NESU