I-RS 2(3) Umshini Wokuluka I-Wap Warp

Imishini Ye-Raschel Yebha Eyodwa: Isixazululo Esikahle Sokukhiqiza I-Net

Imishini ye-Raschel yebha eyodwa ihlinzeka ngesixazululo esisha nesisebenza kahle kakhulu sokukhiqiza izinhlobo ezahlukene zamanetha ezindwangu, okuhlanganisa ezolimo, ukuphepha,

namanetha okudoba. La manetha asebenza ngezindlela eziningi ezahlukene, omunye wemisebenzi yawo eyinhloko ukuvikela ezimeni zesimo sezulu esibi. Ku

lezi zimo, kumele zimelane nokuchayeka njalo emiphumeleni ehlukahlukene yesimo sezulu. Ubuchwepheshe bokunitha be-warp obuthuthukisiwe buhlanganiswe kubha eyodwa ye-Raschel

imishini inikeza amathuba angenakuqhathaniswa okukhiqiza inetha, edlula noma iyiphi enye indlela yokukhiqiza ngokuhlukahluka nokusebenza.

Izici Eziyinhloko Ezithonya Izimpawu Zengqikithi

- I-Lapping technique

- Inani lamabha angumhlahlandlela

- Igeji yomshini

- Ukuhlelwa kochungechunge lwentambo

- Ukuminyana komthungo

- Uhlobo lwentambo esetshenzisiwe

Ngokulungisa le mingcele, abakhiqizi bangakwazi ukuhlanganisa izakhiwo zenethi ukuze zihlangabezane nezidingo ezihlukene zokusetshenziswa kokugcina, njenge:

- Isici sokuvikela ilanga:Ukulawula izinga lomthunzi enikeziwe

- Ukungena komoya:Ukulungisa ukumelana nokugeleza komoya

- Ukufiphala:Ukulawula ukubonakala ngenethi

- Ukuzinza nokunwebeka:Ukushintsha ukuguquguquka eziqondisweni ezinobude neziphambene

I-Basic Lapping Constructions for Net Production

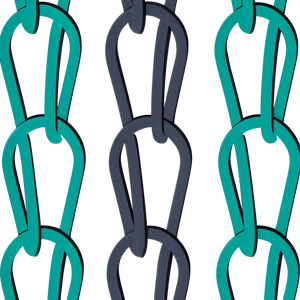

1. Umthungo Wezinsika

Iukwakhiwa kokuthunga insikakuyisisekelo sokukhiqiza inetha kanye nendlela evame ukusetshenziswa kakhulu yokugenca. Iqinisekisa i

okudingekayoamandla obude nokuzinza, okuyenza ibaluleke ukuze ihlale iqinile. Kodwa-ke, ukwenza i-textile substrate esebenzayo,

umthungo wensika kumele uhlanganiswe nei-inlay lappingnoma ezinye izakhiwo ezihambisanayo.

2. Inlay (Weft)

Ngenkathi iisakhiwo se-inlayiyodwa ayikwazi ukwenza i-textile substrate, idlala indima ebalulekile kuyoukuzinza kwe-crosswise. Ngu

ukuxhuma ama-stitch wales amabili, amathathu, noma ngaphezulu, inlay ithuthukisa ukumelana kwendwangu namandla asemaceleni. Ngokuvamile, ama-wales amaningi ajoyina

ndawonye ku-underlap, kukhuluezinzile futhi eqinileinetha iba.

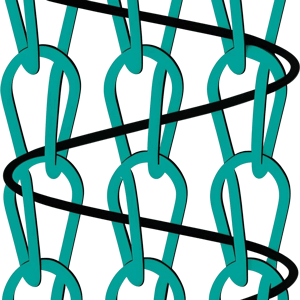

3. I-Tricot Lapping

I-Tricot lapping ifinyelelwa yi-ukushoshozela emaceleniyebha yomhlahlandlela ehlobene nenaliti eseduze. Lapho isetshenziswa ngaphandle kokungeziwe

imigoqo yokuqondisa, iphumela ekubeni kakhuluindwangu elastic. Ngenxa yemvelo yayonokunwebeka okuphezulukokubili ngobude kanye

Izikhombisi-ndlela eziphambanayo, i-tricot lapping ayivamisile ukusetshenziswa ekukhiqizeni inetha-ngaphandle uma kuhlanganiswe nemigoqo yomhlahlandlela eyengeziwe ukuze kuthuthukiswe ukuzinza.

4. 2 x 1 Ukuxhawula

Ngokufana ne-tricot lapping, i2 x 1 ukuqaijoyina i-wales eseduze. Kodwa-ke, esikhundleni sokwenza iluphu elandelayo ngokushesha

inaliti eseduze, idalwa enaliti elandelayo-kodwa-eyodwa. Lesi simiso sisebenza kuma-stitch lappings amaningi, ngaphandle kokuthunga kwezinsika

izakhiwo.

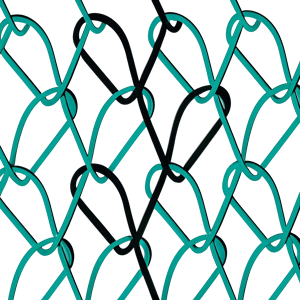

Ukudizayina amanethi anemimo nosayizi abahlukahlukene

Isici esibalulekile sokukhiqiza inetha yikhono lokudala ukuvuleka kwenethaosayizi abahlukene kanye nokwakheka, okufinyelelwa ngokulungisa ukhiye

izici ezifana nalezi:

- Umshiniigeji

- Ukwakhiwa kwe-lapping

- Ukuminyana komthungo

Ngaphezu kwalokho, i-ukuhlelwa kwentambo yokuluthaidlala indima ebalulekile. Ngokungafani nokucushwa okujwayelekile, iphethini yokulutha ayihlali njalo

kufanele ihambisane kahle negeji yomshini. Ukuze ukhulise ukuguquguquka, ukuhlukahluka kokuthunga okufana1 phakathi, 1 ngaphandle or

1 phakathi, 2 ngaphandlezisetshenziswa kaningi. Lokhu kuvumela abakhiqizi ukuthi bakhiqize amanetha ahlukahlukene emshinini owodwa, ukunciphisa isikhathi sokuphumula

kanye nokuqeda isidingo sokushintshashintsha njalo, okudla isikhathi.

Isiphetho: Ukusebenza Okuphezulu Nge-Warp Knitting Technology

Imishini ye-Raschel yebha eyodwa inikezelaukusebenza kahle nokuvumelana nezimo okungenakuqhathaniswaukukhiqizwa kwenetha yendwangu, ukuqinisekisa amazinga aphezulu kakhulu ku

amandla, ukuzinza, kanye nokuhlukahluka komklamo. Ngokusebenzisa ubuchwepheshe bokunitha be-warp obuthuthukisiwe, abakhiqizi bangakwazi ukwenza ngokwezifiso izakhiwo zenetha ukuze kuhlangatshezwane nazo

uhla olukhulu lwezinhlelo zokusebenza zezimboni nokuvikela—ukusetha amabhentshimakhi amasha ekukhiqizeni okuphambili.

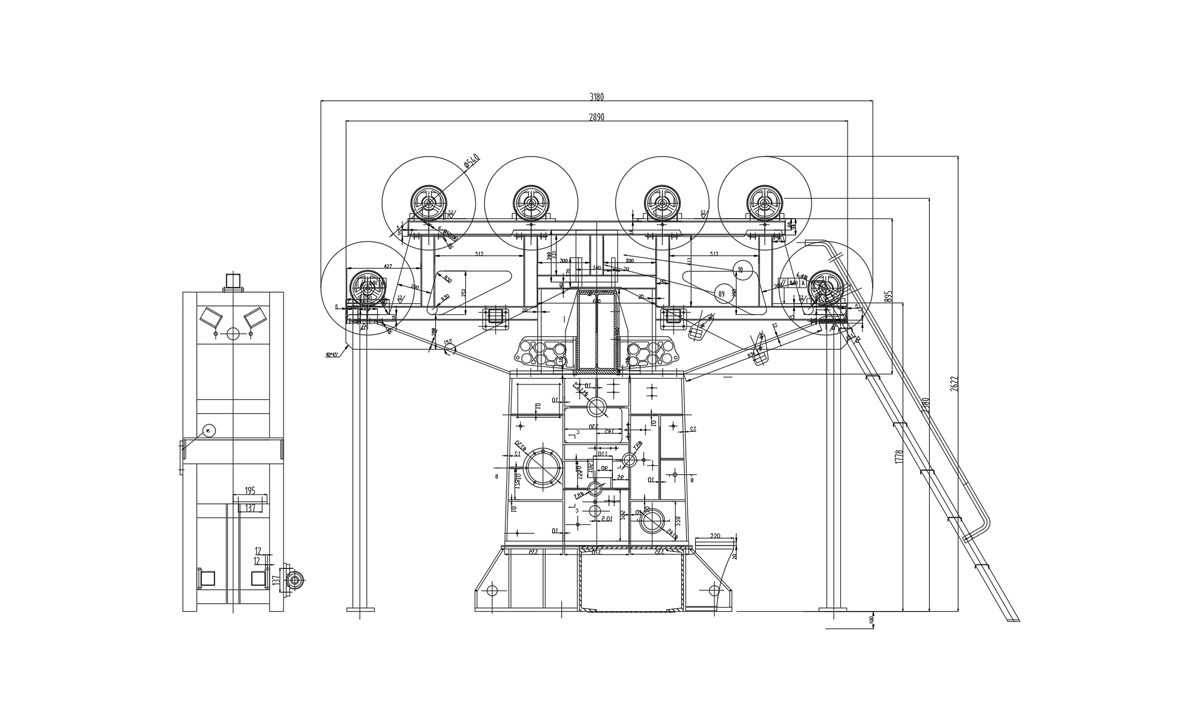

I-GrandStar® Warp Knitting Machine Specifications

Izinketho Zobubanzi Bokusebenza:

- 4597mm (181″)

- 5207mm (205″)

- 6807mm (268″)

- 7188mm (283″)

- 8509mm (335″)

- 10490mm (413″)

- 12776mm (503″)

Izinketho zokukala:

- E2, E3, E4, E5, E6, E8

Izinto zokuluka:

- Ibha yenaliti:Ibha yenaliti engu-1 esebenzisa izinaliti ze-latch.

- Ibha yesilayidi:Ibha yesilayidi engu-1 enamayunithi esilayida sepuleti.

- Ibha ye-Knockover:Ibha engu-1 yokushaya ikamu equkethe amayunithi okushayisa.

- Amabha omhlahlandlela:2(3) amabha omhlahlandlela anamayunithi angumhlahlandlela abunjwe ngokunemba.

- Okubalulekile:Amabha we-magnalium wamandla aphakeme nokudlidliza okuncishisiwe.

Uhlelo Lokuphakela Izintambo:

- Ukusekelwa kwe-Warp Beam:2(3) × 812mm (32″) (i-free-standing)

- I-Yarn Feeding Creel:Ukusebenza kusuka ku-creel

- I-FTL:Ithuluzi lokusika ifilimu kanye ne-strctching

I-GrandStar® Control System:

IGrandStar KOMAND UHLELOinikeza isixhumi esibonakalayo sika-opharetha enembile, evumela ukucushwa komshini okungenazihibe kanye nokulawula okunembayo komsebenzi we-elekthronikhi.

Amasistimu Okuqapha Ahlanganisiwe:

- I-Lastop Ehlanganisiwe:Uhlelo lokuqapha lwesikhathi sangempela oluthuthukisiwe.

Isistimu yokuvala intambo:

Indawo ngayinye ye-warp beam ine-idrayivu yokuvula intambo elawulwa nge-elekthronikhiukuze kulawuleke ukushuba kwesimo.

I-Fabric Take-Up Mechanism:

Ifakwe iuhlelo lokuthatha indwangu olulawulwa nge-elekthronikhiishayelwa injini enembayo ephezulu.

Idivayisi yokuhlanganisa:

A umshini wokugoqa indwangu omele phansi ohlukileiqinisekisa ukuxutshwa kwendwangu ebushelelezi.

I-Pattern Drive System:

- Okujwayelekile:I-N-drive enamaphethini amadiski amathathu kanye negiya elihlanganisiwe lokushintsha i-tempi.

- Ongakukhetha:I-EL-drive enamamotho alawulwa nge-elekthronikhi, evumela imigoqo engumhlahlandlela ukuthi inyakaze ifike ku-50mm (uma uthanda ukunwetshwa ukuya ku-80mm).

Imininingwane kagesi:

- Isistimu yeDrayivu:Idrayivu elawulwa isivinini enomthwalo oxhumene usuwonke ongu-25 kVA.

- Amandla kagesi:380V ± 10%, ugesi wezigaba ezintathu.

- Intambo Yamandla Eyinhloko:Ikhebula elincane elingu-4mm² lezigaba ezintathu lamacore, intambo yaphansi engekho ngaphansi kuka-6mm².

Uhlelo Lokuhlinzeka Uwoyela:

Okuthuthukileisishintshi sokushisa samafutha/amanziiqinisekisa ukusebenza kahle.

Indawo yokusebenza:

- Izinga lokushisa:25°C ± 6°C

- Umswakamo:65% ± 10%

- Ingcindezi Yaphansi:2000-4000 kg/m²

Amanethi e-polyethylene angasindi aklanyelwe ukuvikela utshani namabhala wotshani, kanye nokusimamisa amaphalethi okuthutha. Akhiqizwe ngendlela ekhethekile yokuthunga/i-inlay, lawa manetha afaka ama-wale anezikhala ezibanzi kanye nokuminyana kwezinaliti eziphansi ukuze asebenze kahle. Isistimu yokuhlanganisa iqinisekisa amaroli acindezelwe ngokuqinile anobude obunwetshiwe bokugijima, okwandisa ukusebenza kahle nokugcinwa.

Esetshenziswa kakhulu ezindaweni ezifudumele, amanetha anomthunzi anombala oyi-warp avikela izitshalo kanye nezindawo zokugcina izithombo ekukhanyeni kwelanga okunamandla, avimbele ukuphelelwa amanzi emzimbeni futhi aqinisekise izimo zokukhula ezifanele. Ziphinde zithuthukise ukujikeleza komoya, zinciphise ukwakheka kokushisa endaweni ezinzile.

Ukuvikelwa kwamanziUmshini ngamunye uvalwe kahle ngamaphakeji aphephile olwandle, uhlinzeka ngokuzivikela okuqinile ekulimaleni komswakama kanye namanzi kulo lonke uhambo. | I-International Export-Standard Wooden CasesAmacala ethu okhuni ayinhlanganisela yamandla aphezulu ahambisana ngokugcwele nemithetho yokuthekelisa emhlabeni wonke, eqinisekisa ukuvikeleka okuphelele nokuzinza ngesikhathi sokuthutha. | Esebenza kahle futhi Ethembekile LogisticsKusukela ekuphatheni ngokucophelela endaweni yethu kuya ekulayisheni okungochwepheshe ethekwini, zonke izinyathelo zenqubo yokuthunyelwa kwemikhumbi ziphathwa ngokunemba ukuze kuqinisekiswe ukulethwa okuphephile nokufika ngesikhathi. |

XHUMANA NATHI

XHUMANA NATHI