RS 2 (3) Netting Warp Knitting Machine

Makina a Raschel a Bar One: Njira Yabwino Yopangira Net Production

Makina a single-bar Raschel amapereka njira yatsopano komanso yothandiza kwambiri popanga maukonde amitundu yosiyanasiyana, kuphatikiza ulimi, chitetezo,

ndi maukonde ophera nsomba. Maukondewa amagwira ntchito zosiyanasiyana, ndipo imodzi mwa ntchito zawo zazikulu ndikuteteza kunyengo. Mu

milandu imeneyi, ayenera kupirira nthawi zonse kukhudzana ndi kusintha kwa nyengo. Ukadaulo wapamwamba kwambiri woluka wa warp wophatikizidwa mu Raschel wabar imodzi

makina amapereka mwayi wosayerekezeka wopanga maukonde, kuposa njira ina iliyonse yopangira zinthu zosiyanasiyana komanso magwiridwe antchito.

Zofunika Kwambiri Zomwe Zimayambitsa Makhalidwe Abwino

- Lapping technique

- Chiwerengero cha mipiringidzo

- Makina owerengera

- Kupanga ulusi wa ulusi

- Kachulukidwe ka msoko

- Mtundu wa ulusi wogwiritsidwa ntchito

Posintha magawowa, opanga amatha kusintha mawonekedwe a ukondewo kuti akwaniritse zofunikira zogwiritsa ntchito kumapeto, monga:

- Chitetezo cha dzuwa:Kulamulira mlingo wa mthunzi woperekedwa

- Mphepo permeability:Kusintha kukana kwa mpweya

- Kuwonekera:Kuwongolera mawonekedwe kudzera mu ukonde

- Kukhazikika ndi elasticity:Kusintha kusinthasintha munjira zazitali komanso zopingasa

Basic Lapping Constructions for Net Production

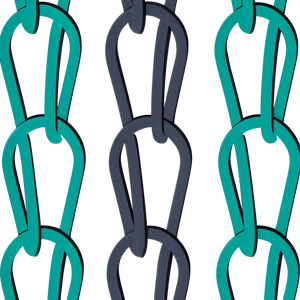

1. Msuzi wa Nsanamira

Thekumanga msanamirandiye maziko opangira maukonde komanso njira yomwe imagwiritsidwa ntchito kwambiri pakuluka. Zimatsimikizira za

zofunikakutalika mphamvu ndi kukhazikika, kupangitsa kuti ikhale yofunikira kuti ikhale yolimba. Komabe, kupanga gawo lapansi logwira ntchito la nsalu,

nsonga ya nsanamira iyenera kuphatikizidwa ndikuwotcha mkatikapena zina zowonjezera.

2. Inlay (Weft)

Pamene akapangidwe ka inlaychokha sichingapange gawo lapansi la nsalu, limagwira ntchito yofunika kwambiricrosswise bata. Wolemba

kulumikiza awiri, atatu, kapena kuposerapo wales, inlay kumawonjezera kukana kwa nsalu ku mphamvu lateral. Nthawi zambiri, ma wales ambiri adalumikizana

pamodzi mu chinsalu, kwambiriwokhazikika komanso wokhazikikaukonde umakhala.

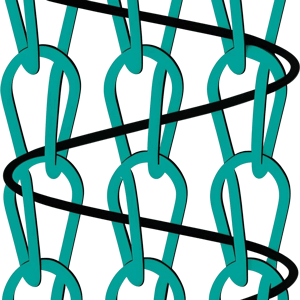

3. Tricot Lapping

Tricot lapping imatheka ndikuwombera m'mbaliwa kalozera wokhudzana ndi singano yoyandikana nayo. Mukagwiritsidwa ntchito popanda zowonjezera

kutsogolera mipiringidzo, zimabweretsa kwambirizotanuka nsalu. Chifukwa cha chibadwa chakemkulu elasticitymu utali ndi

mayendedwe odutsa, kukwera kwa tricot sikumagwiritsidwa ntchito kawirikawiri popanga maukonde-pokhapokha ataphatikizidwa ndi mipiringidzo yowonjezerapo kuti mukhale bata.

4. 2 x 1 Kuthamanga

Zofanana ndi tricot lapping, ndi2 x 1 paamalumikizana ndi wales pafupi. Komabe, m'malo kupanga kuzungulira lotsatira pa yomweyo

singano yoyandikana, imapangidwa pa singano yotsatira-koma-imodzi. Mfundo imeneyi imagwira ntchito pa zomangira zambiri zoluka, kupatulapo nsonga za mzati

zomangamanga.

Kupanga Maukonde okhala ndi Maonekedwe Osiyanasiyana ndi Makulidwe Osiyanasiyana

Chofunikira kwambiri pakupanga ma neti ndi kuthekera kopanga maukonde otsegukamakulidwe osiyanasiyana ndi mawonekedwe, zomwe zimatheka posintha kiyi

zinthu monga:

- Makinagauge

- Lapping kupanga

- Kachulukidwe ka msoko

Kuphatikiza apo, thekupanga ulusi wa ulusiamatenga gawo lalikulu. Mosiyana ndi masinthidwe wamba, mawonekedwe a ulusi samakhala nthawi zonse

amayenera kuyanjanitsa bwino ndi makina gauge. Kuti muwonjezere kusinthasintha, kusinthasintha kosiyanasiyana monga1 ku,1 ku or

1 ku,2 kuamagwiritsidwa ntchito pafupipafupi. Izi zimathandiza opanga kupanga maukonde osiyanasiyana pa makina amodzi, kuchepetsa nthawi yopuma

ndi kuthetsa kufunika kosintha pafupipafupi, kowononga nthawi.

Kutsiliza: Kuchita Bwino Kwambiri ndi Warp Knitting Technology

Makina a single-bar Raschel amaperekakusachita bwino komanso kusinthasinthakupanga ukonde wa nsalu, kuwonetsetsa kuti zinthu zili bwino kwambiri

mphamvu, kukhazikika, ndi kusinthasintha kwapangidwe. Pogwiritsa ntchito ukadaulo wapamwamba kwambiri woluka, opanga amatha kusintha mwamakonda ma ukonde kuti akwaniritse

ntchito zambiri zamafakitale ndi zoteteza-kukhazikitsa zizindikiro zatsopano pakupanga bwino.

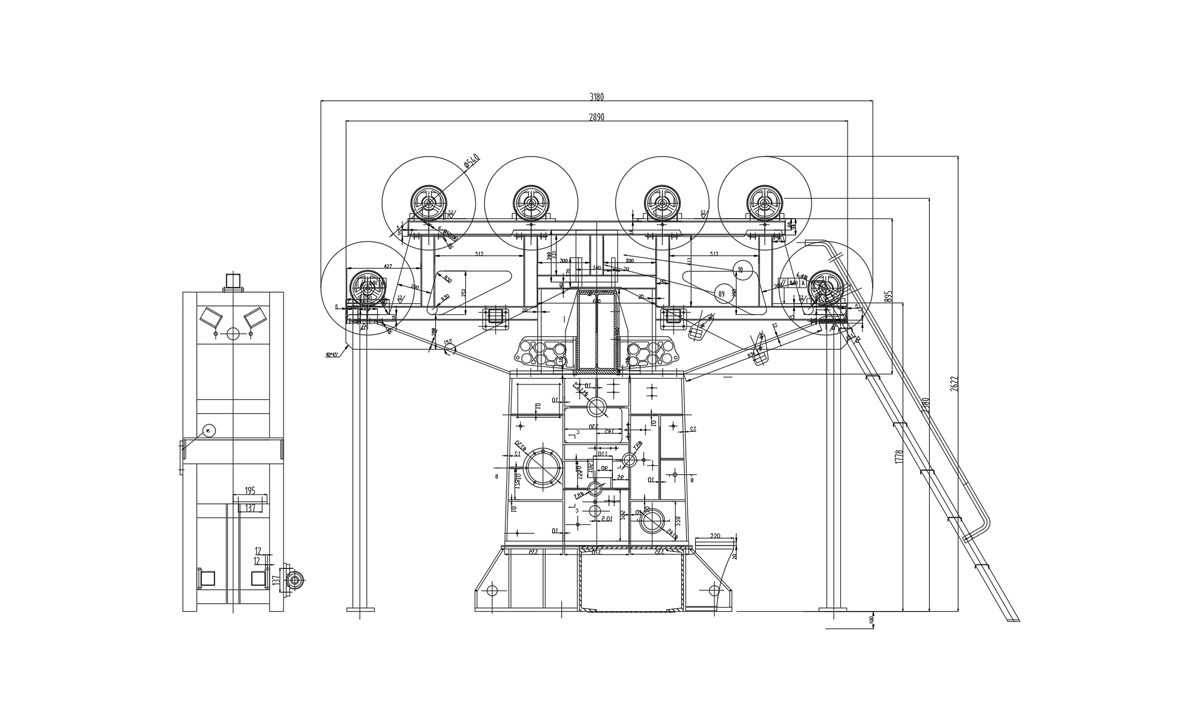

GrandStar® Warp Knitting Machine Zofotokozera

Zosankha Zogwira Ntchito:

- 4597mm (181 ″)

- 5207mm (205 ″)

- 6807mm (268 ″)

- 7188mm (283 ″)

- 8509mm (335 ″)

- 10490mm (413 ″)

- 12776mm (503 ″)

Zosankha za Gauge:

- E2, E3, E4, E5, E6, E8

Zoluka:

- Nangano:1 singano imodzi yogwiritsira ntchito singano za latch.

- Slider Bar:1 slider bar yokhala ndi ma slider mayunitsi.

- Knockover Bar:1 kugogoda pa chisa chokhala ndi mayunitsi ogogoda.

- Mabala Otsogolera:2(3) zitsulo zowongolera zokhala ndi magawo owongolera olondola.

- Zofunika:mipiringidzo ya magnalium kuti ikhale yamphamvu kwambiri komanso kuchepetsa kugwedezeka.

Njira Yodyetsera Ulusi:

- Chithandizo cha Warp Beam:2(3) × 812mm (32″) (yoyima mwaulere)

- Nsalu Yodyetsa Ulusi:Kugwira ntchito kuchokera ku creel

- FTL:Kudula Mafilimu ndi strctching chipangizo

GrandStar® Control System:

TheGrandStar COMMAND SYSTEMimapereka mawonekedwe opangira mwachilengedwe, kulola kusinthika kwa makina osasunthika komanso kuwongolera magwiridwe antchito amagetsi.

Integrated Monitoring Systems:

- Integrated Lastop:Njira yowunikira nthawi yeniyeni.

Dongosolo Lolekanitsa Ulusi:

Malo aliwonse a warp amakhalanso ndipakompyuta ankalamulira ulusi kusiya galimotokuti muthetse bwino kupsinjika maganizo.

Njira Yopangira Nsalu:

Okonzeka ndimakina opangidwa ndi nsalu yotengera nsaluyoyendetsedwa ndi injini yolondola kwambiri.

Chipangizo cha Batching:

A chipangizo chodzigudubuza choyala pansiamaonetsetsa kuti batching yosalala nsalu.

Dongosolo Lamagalimoto Amitundu:

- Zokhazikika:N-drive yokhala ndi ma disks atatu amtundu komanso zida zosinthira tempi.

- Zosankha:EL-drive yokhala ndi ma mota oyendetsedwa ndimagetsi, kulola mipiringidzo yowongolera mpaka 50mm (posankha kukulitsa 80mm).

Zamagetsi:

- Dongosolo Loyendetsa:Kuthamanga-kuyendetsa galimoto ndi katundu wokhudzana ndi 25 kVA.

- Voteji:380V ± 10%, magawo atatu amagetsi.

- Main Power Cord:Chingwe chochepera 4mm² magawo atatu apakati-chinai, waya wapansi wosachepera 6mm².

Njira Yopangira Mafuta:

Zapamwambamafuta / madzi kutentha exchangerzimatsimikizira magwiridwe antchito abwino.

Malo Ogwirira Ntchito:

- Kutentha:25°C ± 6°C

- Chinyezi:65% ± 10%

- Kupanikizika Pansi:2000-4000 kg / m²

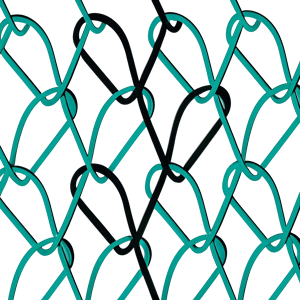

Maukonde opepuka a polyethylene opangidwa kuti ateteze udzu ndi mabale a udzu, komanso kukhazikika kwa mapaleti oyendera. Maukondewa amapangidwa ndi luso lapadera la nsonga/zoyikapo, ndipo amakhala ndi mipata yotalikirana motalikirapo komanso osachulukirachulukira singano kuti agwire bwino ntchito. Dongosolo la batching limatsimikizira mipukutu yolimba kwambiri yokhala ndi utali wothamanga, kukulitsa luso komanso kusunga.

Amagwiritsidwa ntchito kwambiri m'madera otentha, maukonde opangidwa ndi mithunzi yowongoka amateteza mbewu ndi nyumba zobiriwira ku dzuwa, kuteteza kutaya madzi m'thupi komanso kuonetsetsa kuti zinthu zikule bwino. Amathandiziranso kuyenda kwa mpweya, kuchepetsa kutentha kwa malo okhazikika.

Chitetezo Chopanda MadziMakina aliwonse amasindikizidwa bwino ndi zoyika zotetezedwa panyanja, kupereka chitetezo champhamvu ku chinyezi ndi kuwonongeka kwamadzi panthawi yonse yodutsa. | Milandu Yamatabwa Yapadziko Lonse-Standard WoodenMilandu yathu yamatabwa yokhala ndi mphamvu zambiri imagwirizana kwathunthu ndi malamulo otumiza kunja padziko lonse lapansi, kuonetsetsa chitetezo chokwanira komanso bata panthawi yamayendedwe. | Mayendedwe Oyenera & OdalirikaKuchokera pakusamalira mosamala pamalo athu mpaka kukayika kwa ziwiya zaukatswiri padoko, gawo lililonse lamayendedwe otumizira limayendetsedwa mwatsatanetsatane kuti zitsimikizire kutumizidwa kotetezeka komanso munthawi yake. |

LUMIKIZANANI NAFE

LUMIKIZANANI NAFE