RS 2 (3) Netting Warp Knitting Tshuab

Ib leeg-Bar Raschel Machine: Qhov Zoo Tshaj Plaws rau Kev Tsim Nyog

Ib leeg-bar Raschel cov cav tov muab cov kev daws teeb meem tshiab thiab muaj txiaj ntsig zoo rau kev tsim ntau hom textile nets, suav nrog kev ua liaj ua teb, kev nyab xeeb,

thiab nuv ntses nets. Cov nets no pab ntau yam kev siv, nrog rau ib qho ntawm lawv cov haujlwm tseem ceeb yog kev tiv thaiv huab cua phem. Hauv

cov xwm txheej no, lawv yuav tsum tiv taus qhov cuam tshuam tsis tu ncua rau kev hloov pauv huab cua. Lub tshuab thev naus laus zis warp knitting tau muab tso rau hauv ib leeg-bar Raschel

machines muaj unmatched possibilities rau net ntau lawm, surpassing lwm yam manufacturing txoj kev nyob rau hauv versatility thiab kev ua tau zoo.

Cov yam tseem ceeb cuam tshuam rau Net yam ntxwv

- Lapping txheej txheem

- Tus naj npawb ntawm cov ntawv qhia bar

- Tshuab ntsuas

- Cov xov paj threading arrangement

- Stitch ceev

- Hom xov paj siv

Los ntawm kev kho cov kev txwv no, cov tuam txhab lag luam tuaj yeem kho cov khoom lag luam kom tau raws li cov kev xav tau siv kawg, xws li:

- Sun Protection factor:Tswj cov qib ntawm qhov ntxoov ntxoo muab

- Cua permeability:Kho airflow kuj

- Opacity:Regulating visibility los ntawm net

- Stability thiab elasticity:Hloov kho qhov yooj yim hauv lengthwise thiab crosswise cov lus qhia

Tsim Nyog Lapping Kev Tsim Kho rau Net Production

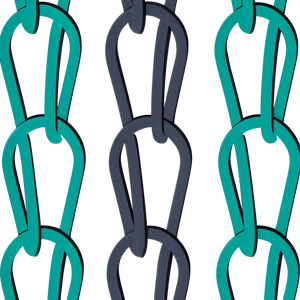

1. Pillar Stitch

Covpillar stitch kev tsim khoyog lub hauv paus rau net manufacturing thiab feem ntau siv cov txheej txheem lapping. Nws ua kom cov

xav taulengthwise zog thiab stability, ua rau nws tseem ceeb rau net durability. Txawm li cas los xij, los tsim kom muaj kev ua haujlwm ntawm textile substrate,

tus ncej stitch yuav tsum tau ua ke nrog ib qhoinlay lappinglos yog lwm cov qauv ua ke.

2. Inlay (Weft)

Thaum ibinlay qauvib leeg tsis tuaj yeem tsim textile substrate, nws plays lub luag haujlwm tseem ceeb hauvcrosswise stability. Los ntawm

interconnecting ob, peb, los yog ntau tshaj stitch wales, lub inlay txhim khu cov ntaub tsis kam mus rau lateral rog. Feem ntau, cov wales koom nrog ntau dua

ua ke nyob rau hauv ib tug underlap, ntauruaj khov thiab resilientnet ua.

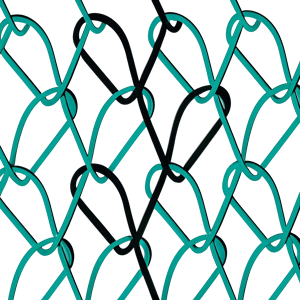

3. Tricot Lapping

Tricot lapping yog tiav los ntawmsab shoggingntawm daim ntawv qhia bar txheeb ze rau rab koob uas nyob ib sab. Thaum siv yam tsis muaj ntxiv

coj bars, nws ua rau ib tug heevelastic ntaub. Vim nws lub hauv paussiab elasticitynyob rau hauv ob qho tib si lengthwise thiab

crosswise cov lus qhia, tricot lapping yog tsis tshua muaj siv nyob rau hauv net manufacturing-tshwj tsis yog ua ke nrog ntxiv cov lus qhia tuav los txhim kho stability.

4.2 x 1 Lapping

Zoo ib yam li tricot lapping, lub2 x 1 lwgkoom nrog wales uas nyob ib sab. Txawm li cas los xij, es tsis txhob tsim lub voj tom ntej ntawm qhov tam sim ntawd

koob uas nyob ib sab, nws yog tsim nyob rau tom ntej-tab sis-ib koob. Lub hauv paus ntsiab lus no siv rau feem ntau stitch lappings, nrog rau kev zam ntawm pillar stitch

kev tsim kho.

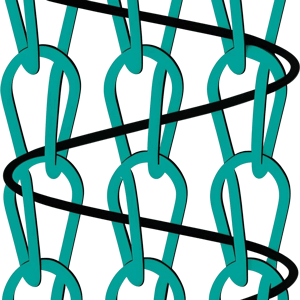

Tsim cov Nets nrog ntau qhov sib txawv thiab qhov ntau thiab tsawg

Ib qho tseem ceeb ntawm kev tsim cov khoom lag luam yog lub peev xwm los tsim cov net qhib hauvtxawv qhov ntau thiab tsawg, uas yog ua tiav los ntawm kev hloov kho qhov tseem ceeb

yam xws li:

- Tshuabntsuas

- Lapping kev tsim kho

- Stitch ceev

Tsis tas li ntawd, lubxov paj threading kev npajplays lub luag haujlwm txiav txim siab. Tsis zoo li cov qauv kev teeb tsa, cov qauv threading tsis tas li

yuav tsum ua kom zoo zoo nrog lub tshuab ntsuas. Txhawm rau ua kom yooj yim, threading variations xws li1in,1 ua or

1in,2 uanquag siv. Qhov no tso cai rau cov tuam txhab tsim cov khoom sib txawv ntawm cov nets ntawm ib lub tshuab, txo qis qis qis

thiab tshem tawm qhov xav tau ntawm kev hloov pauv tsis tu ncua, siv sijhawm ntev.

Xaus: Ua tau zoo tshaj plaws nrog Warp Knitting Technology

Ib leeg-bar Raschel tshuab muabunrivaled efficiency thiab adaptabilityrau textile net ntau lawm, kom ntseeg tau cov qauv siab tshaj plaws hauv

zog, stability, thiab tsim versatility. Los ntawm leveraging advanced warp knitting tshuab, manufacturers tau seamlessly customize net khoom kom tau raws li

ntau ntau ntawm kev lag luam thiab kev tiv thaiv daim ntawv thov - teeb tsa cov qauv tshiab hauv kev tsim khoom zoo tshaj plaws.

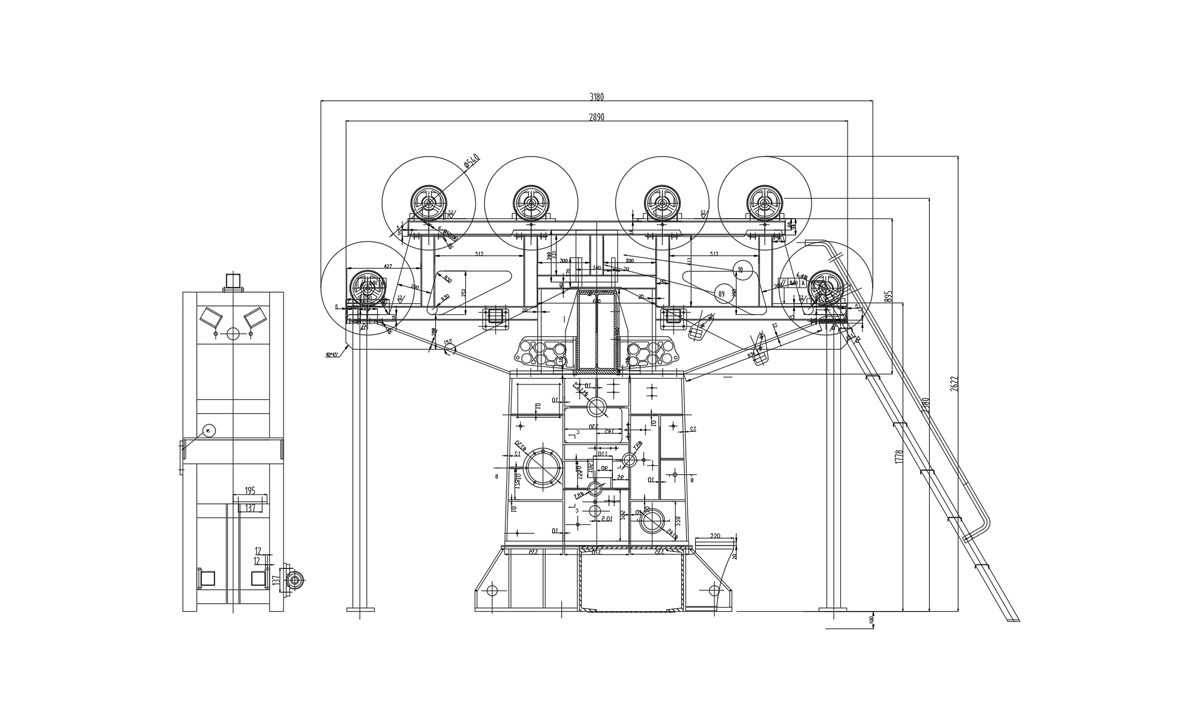

GrandStar® Warp Knitting Tshuab Specifications

Ua hauj lwm dav Options:

- 4597 hli (181 ")

- 5207 hli (205 ")

- 6807 hli (268 ")

- 7188 hli (283 ")

- 8509mm (335 ")

- 10490 hli (413 ")

- 12776 hli (503 ")

Gauge Options:

- E2, E3, E4, E5, E6, E8

Knitting Elements:

- Koob Bar:1 ib rab koob bar siv cov koob latch.

- Slider Bar:1 slider bar nrog phaj slider units.

- Knockover Bar:1 khob ntawm comb bar featuring knock-over units.

- Qhia Bars:2 (3) qhia tuav nrog precision-engineered qhia units.

- Khoom siv:magnalium tuav rau superior zog thiab txo kev co.

Xov Paj Feeding System:

- Warp Beam Support:2 (3) × 812mm (32 ") (dawb-sawv)

- Yarn Feeding Creel:Ua haujlwm los ntawm creel

- FTL:Zaj duab xis txiav thiab strctching ntaus ntawv

GrandStar® Control System:

CovGrandStar COMMAND SYSTEMmuab tus neeg teb xov tooj intuitive interface, tso cai seamless tshuab configuration thiab meej hluav taws xob muaj nuj nqi tswj.

Integrated Monitoring Systems:

- Integrated Laserstop:Advanced real-time xyuas system.

Yarn Let-Off System:

Txhua warp beam txoj hauj lwm nta ibelectronically tswj yarn cia-tawm tsavrau cov kev cai nruj nruj.

Fabric Take-Up Mechanism:

Nruab nrog ibelectronically tswj ntaub take-up systemtsav los ntawm high-precision geared motor.

Batching Device:

A cais pem teb-sawv ntaub rolling devicekom cov ntaub batching du.

Qauv Tsav System:

- Txheem:N-tsav nrog peb tus qauv discs thiab kev sib xyaw tempi hloov iav.

- Yeem:EL-tsav nrog lub tshuab hluav taws xob tswj hluav taws xob, tso cai rau cov ntawv qhia kom shog txog 50mm (optional extension to 80mm).

Hluav taws xob Specifications:

- Tsav System:Kev tswj ceev ceev nrog tag nrho cov kev sib txuas ntawm 25 kVA.

- Voltage:380V ± 10%, peb-theem fais fab mov.

- Main Power Cord:Yam tsawg kawg nkaus 4mm² peb-theem plaub-core cable, hauv av xaim tsis pub tsawg tshaj 6mm².

Oil Supply System:

Advancedroj / dej kub exchangerua kom pom kev ua haujlwm zoo.

Kev ua haujlwm ib puag ncig:

- Kub:25 ° C ± 6 ° C

- Humidity:65% ± 10%

- Pem Teb Siab:2000-4000 kg / m²

Lub teeb yuag polyethylene nets tsim los rau kev ruaj ntseg quav nyab thiab straw bales, nrog rau kev ruaj khov pallets rau kev thauj mus los. Ua los ntawm cov pillar tshwj xeeb stitch / inlay txheej txheem, cov nets feature dav spaced wales thiab ib rab koob tsawg rau kev ua tau zoo. Lub batching system xyuas kom nruj compressed rolls nrog ncua kev khiav ntev, maximizing efficiency thiab cia.

Dav siv nyob rau hauv huab cua sov, warp-knitted ntxoov ntxoo nets tiv thaiv cov qoob loo thiab tsev cog khoom los ntawm lub hnub ci hnyav, tiv thaiv lub cev qhuav dej thiab ua kom pom kev loj hlob zoo. Lawv kuj txhim kho huab cua ncig, txo cov cua sov tsim kom muaj qhov chaw ruaj khov dua.

Kev tiv thaiv dej tsis zooTxhua lub tshuab yog meticulously kaw nrog hiav txwv-safe ntim, muab kev tiv thaiv zoo tiv thaiv ya raws thiab dej puas tsuaj thoob plaws hauv kev thauj mus los. | International Export-Standard Ntoo CasesPeb lub zog muaj zog sib xyaw ntoo ua tiav raws li kev cai xa tawm thoob ntiaj teb, ua kom muaj kev tiv thaiv zoo thiab ruaj khov thaum thauj. | Ua haujlwm tau zoo & txhim khu kev qha LogisticsLos ntawm kev ua tib zoo tuav ntawm peb qhov chaw mus rau cov kws tshaj lij lub thawv thauj khoom ntawm qhov chaw nres nkoj, txhua kauj ruam ntawm cov txheej txheem thauj khoom raug tswj hwm nrog qhov tseeb los lav kev nyab xeeb thiab xa khoom raws sijhawm. |

Tiv tauj peb

Tiv tauj peb