Direct Warping Tshuab Rau Filament

Ncaj qhaWarping Tshuabrau Filament Yarn

CovNcaj qhaWarping Tshuabsawv cev rau lub pinnacle ntawm precision engineering nyob rau hauv filament yarn npaj, xa unmatched sib xws, efficiency, thiab beam zoo rau warp knitting ntau lawm. Tsim los rauDaim ntawv thov DTY thiab FTY, nws yog dav saws hla cov tshuab tricot, ob rab koob bar raschel cov cav tov, thiab lwm yam kev ua haujlwm siab heev.

Intelligent Control rau Superior Consistency

Nyob rau hauv lub plawv ntawm lub system yog ib tug tag nrho computerized, real-time daim ntawv soj ntsuam platform. Qhov no xyuas kom meej tiastension fluctuations thiab deviations yog minimized, ua cov kab teeb warp nrog zoo repeatability. Los ntawm guaranteeing siab beam-rau-beam sib xws, manufacturers tau txais txiaj ntsig los ntawmtseem ceeb raw khoom txuag thiab txo pov tseg, ncaj qha txhim khu kev lag luam ntau lawm.

Advanced Mechanical Design

Lub tshuab ntapneumatic beam thiab tailstock positioning, muab cov qauv kev ruaj ntseg, kev sib dhos meej, thiab kev ua haujlwm tsis muaj zog. Nwsreplication muaj nuj nqitso cai rau duplication ntawm warp beams raws li khaws cia beam cov ntaub ntawv, xyuas kom meej reproducibility nyob rau hauv ntau ntau lawm cycles thiab simplifying beam npaj rau high-volume xav tau.

Kev Ua Haujlwm Zoo

- Warping ceev mus txog 1000 m / minrau accelerated throughput

- Cov cuab yeej siv siab rau cov menyuam (yeem)xa cov ntev warp ntev thiab ntau dua beam hardness

- Cov xov paj cia chav tsev nrog 9 m rov qab-winding muaj peev xwm, enabling tag nrho tswj ntawm qhov kawg warp daim ntawv ntev

- Tsis siv neeg yarn nruj tswjrau ruaj khov, zoo warping

- Siab ntse nres synchronizationlav qhov chaw nres tsheb thiab kev nyab xeeb

- Beam zoo optimizationlos ntawm qhov siab tshaj beam ncig tswj

- Integrated zoo raws tu qauv tswjnrog beam cov ntaub ntawv cia rau traceability

- Ergonomic tsimhaum rau tus neeg teb xov tooj kev nplij siab thiab kev ua haujlwm zoo

Pov thawj kev ntseeg thiab kev ua lag luam Reputation

Nrog dhau15 xyoo ntawm kev tsim khoom, peb Direct WarpingCov tshuabtau txais lub koob npe nrov hauv ntiaj teb kev lag luam textile. Kev txhawb nqa los ntawm cov kev pabcuam hauv online thiab kev pabcuam kev pabcuam, lawv ua kerobust engineering nrog ntse automation, ua rau lawv nyiam kev xaiv ntawm kev ua lag luam warp knitting thoob ntiaj teb.

Kev sib tw Edge

Tsis zoo li ntau lwm cov kev xaiv, peb Direct Warping Tshuab integratesadvanced digital tswj, ntau dua productivity, thiab superior reproducibilityhauv ib lub platform. Txawm hais tias cov neeg sib tw feem ntau vam khom ib nrab ntawm automation lossis kev hloov kho phau ntawv, peb xa ibtag nrho synchronized systemuas maximizes uptime, minimizes khoom poob, thiab tsis tu ncua ua tiav covpremium beam zooxav tau los ntawm niaj hnub warp knitting ua haujlwm.

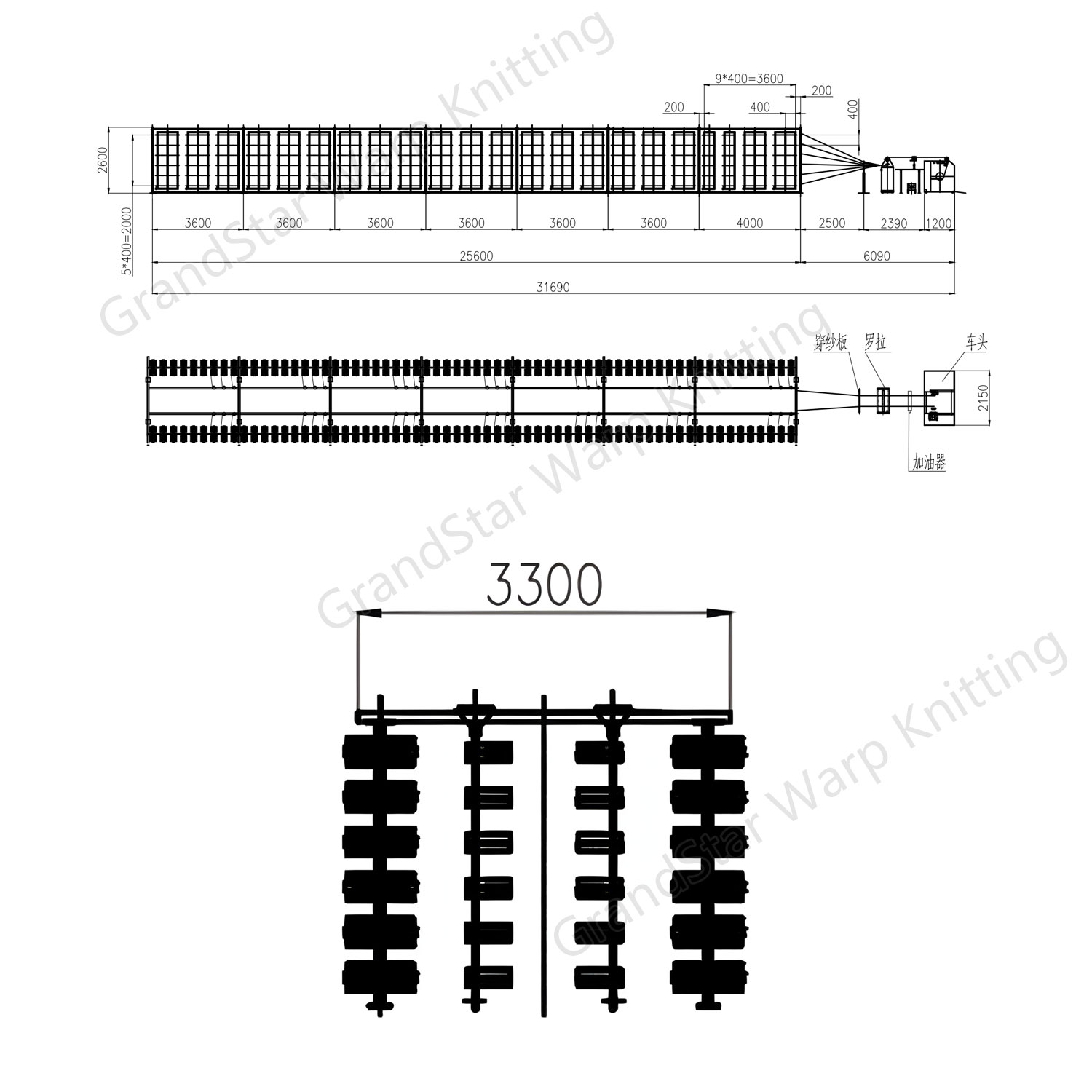

Direct Warping Tshuab - Technical Specifications

Peb lub tshuab warping ncaj qha yog engineered xaMaximum efficiency, precision, thiab kev cia siabrau premium warp knitting ua haujlwm. Txhua qhov nthuav dav yog tsim los hloov cov kev ua tau zoo rau hauv cov neeg siv khoom muaj nqis.

Cov ntaub ntawv tseem ceeb

- Qhov siab tshaj plaws Warping ceev: 1,200 m / min

Ua tiav cov khoom tsim tau zoo tshaj plaws nrog kev lag luam-kev ceev ceev thaum tswj cov xov paj zoo ib yam. - Warp Beam Qhov ntau thiab tsawg: 21 "× (inch), 21" × 30 ″ (inch), thiab customized ntau thiab tsawg muaj

Flexibility kom tau raws li ntau yam kev xav tau thiab cov neeg siv khoom tshwj xeeb. - Computer Real-Time Control & Monitoring

Intelligent system ua kom meej meej, txuas ntxiv saib xyuas cov txheej txheem nrog kev ua haujlwm zoo ntawm tus neeg teb xov tooj. - Tension Roller nrog PID Kaw-Loop Kho

Real-time yarn tension control guarantees uniform winding zoo thiab minimizes ntau lawm tsis xws luag. - Hydropneumatic Beam Handling System (Up / Down, Clamping, Nres)

Robust automation muab kev ua haujlwm tsis muaj zog, kev tuav pov hwm kev nyab xeeb, thiab kev siv lub tshuab txuas ntxiv. - Direct Pressure Press Roll nrog Kick-Rov Qab Tswj

Muab cov xov paj ruaj khov txheej txheej thiab tiv thaiv slippage, txhim kho beam raug. - Lub cev muaj zog: 7.5 kW AC Frequency-Controlled Drive

Tswj kom tsis tu ncua linear ceev los ntawm kaw-circuit tswj kom du, zog-npaum kev ua haujlwm. - Brake Torque: 1,600 Nm

Lub zog braking system ua kom cov lus teb sai thiab txhim khu kev nyab xeeb thaum lub sijhawm khiav ceev. - Cua Txuas: 6 bar

Optimized pneumatic kev koom ua ke rau txhim khu kev qha auxiliary functions thiab zoo ib yam tshuab kev ua tau zoo. - Copy Precision: yuam kev ≤ 5 m rau 100,000 m

High-precision warping kom paub meej cov ntaub zoo, txo cov khib nyiab thiab ua kom muaj txiaj ntsig zoo. - Kev suav ntau tshaj plaws: 99,999 m (ib lub voj voog)

Kev ntsuas kev muaj peev xwm txuas ntxiv txhawb kev ua haujlwm ntev yam tsis muaj kev cuam tshuam.

Vim li cas cov neeg siv khoom xaiv lub tshuab no

- Tsis sib haum xeeb Productivity:Kev kub ceev ua ke nrog kev tswj xyuas kom luv luv lub sij hawm txhuas.

- Premium Quality Output:Kaw-voj nro system ua kom cov ntaub ntawv flawless.

- Flexible Adaptability:Ntau yam ntawm cov nqaj loj thiab cov kev xaiv customization.

- Operator-Friendly Design:Automated hydropneumatic tuav txo kev siv zog.

- Pov thawj Reliability:Engineered rau lub sij hawm ntev durability nrog cov neeg tseem ceeb cov qauv kev nyab xeeb.

Daim ntawv qhia tshwj xeeb no qhia txogGrandStar txoj kev cog lus los teeb tsa qhov ntsuas hauv kev siv tshuab warp knitting. Peb lub tshuab warping ncaj qha txhawb cov tuam ntxhab kom ua tiavkev tsim khoom sai dua, kev ua tau zoo dua, thiab kev sib tw muaj zognyob rau hauv lub ntiaj teb no textile lag luam.

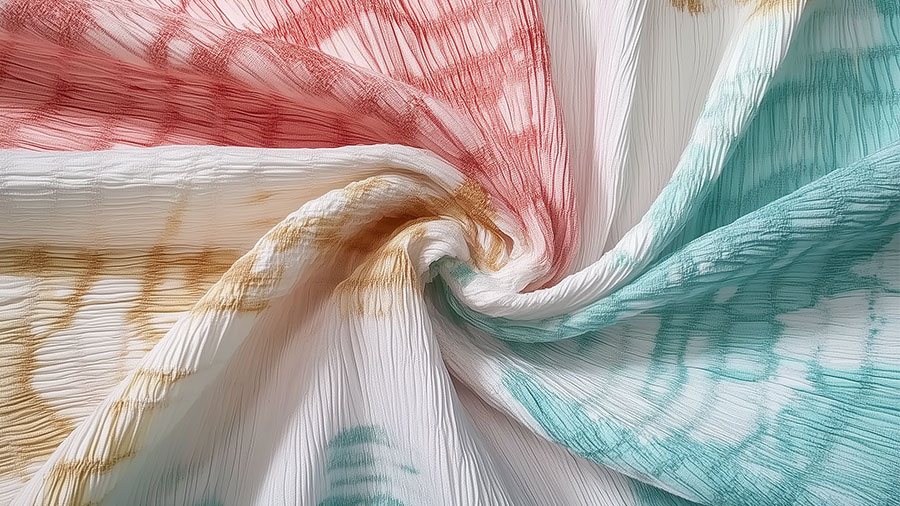

Warp knitting ua ke nrog cov txheej txheem crinkling tsim warp knitting crinkle ntaub. Cov ntaub no muaj qhov ncab, textured nto nrog cov nyhuv me me, ua tiav los ntawm kev txuas ntxiv rab koob txav nrog EL. Nws elasticity sib txawv raws li kev xaiv cov xov paj thiab knitting txoj kev.

Nruab nrog EL system, GrandStar warp knitting tshuab tuaj yeem tsim cov kis las mesh fabrics nrog ntau qhov tshwj xeeb thiab cov qauv, haum rau cov xov paj sib txawv thiab cov qauv xav tau. Cov ntaub mesh no txhim kho breathability, ua rau lawv zoo tagnrho rau cov khaub ncaws ncaws pob.

Peb cov tshuab warp knitting tsim cov khoom zoo velvet / tricot fabrics nrog cov teebmeem tshwj xeeb. Cov pawg yog tsim los ntawm pem hauv ntej bar (bar II), thaum lub rear bar (bar I) tsim ib tug ntom, ruaj khov knitted puag. Cov qauv ntaub sib xyaw ua ke ib qho yooj yim thiab counter notation tricot kev tsim kho, nrog rau hauv av qhia tuav kom paub meej cov xov paj tso rau kev pom kev zoo nkauj thiab durability.

Warp knitting machines los ntawm GrandStar pab kom tsim tau cov kev ua tau zoo ntawm tsheb sab hauv fabrics. Cov ntaub no yog tsim los siv cov txheej txheem plaub-comb braiding tshwj xeeb ntawm cov tshuab Tricot, kom ntseeg tau tias muaj zog thiab yoog raws. Qhov tshwj xeeb warp knitting qauv tiv thaiv wrinkling thaum sib koom nrog cov vaj huam sib luag sab hauv. Zoo tagnrho rau cov ceilings, skylight panels, thiab lub cev npog.

Tricot warp knitted khau ntaub muaj durability, elasticity, thiab breathability, kom ntseeg tau ib tug snug tsis tau xis haum. Engineered rau kis las thiab khau xws li khau, lawv tiv taus hnav thiab tsim kua muag thaum tuav lub teeb pom kev zoo rau kev nplij siab.

Warp-knitted fabrics muaj qhov tshwj xeeb ncab thiab rov zoo, ua kom muaj kev ywj pheej thiab kev ywj pheej ntawm kev txav mus rau yoga xyaum. Lawv yog cov breathable thiab noo noo-wicking, ua kom lub cev txias thiab qhuav thaum lub sij hawm khaus. Nrog superior durability, cov ntaub no tiv taus stretching, khoov, thiab ntxuav. Seamless kev tsim kho txhim khu kev nplij siab, txo kev sib txhuam.

Main Warper | Roller Rau Warper | Creel rau Warper |

Kev tiv thaiv dej tsis zooTxhua lub tshuab yog meticulously kaw nrog hiav txwv-safe ntim, muab kev tiv thaiv zoo tiv thaiv ya raws thiab dej puas tsuaj thoob plaws hauv kev thauj mus los. | International Export-Standard Ntoo CasesPeb lub zog muaj zog sib xyaw ntoo ua tiav raws li kev cai xa tawm thoob ntiaj teb, ua kom muaj kev tiv thaiv zoo thiab ruaj khov thaum thauj. | Ua haujlwm tau zoo & txhim khu kev qha LogisticsLos ntawm kev ua tib zoo tuav ntawm peb qhov chaw mus rau cov kws tshaj lij lub thawv thauj khoom ntawm qhov chaw nres nkoj, txhua kauj ruam ntawm cov txheej txheem thauj khoom raug tswj hwm nrog qhov tseeb los lav kev nyab xeeb thiab xa khoom raws sijhawm. |

Tiv tauj peb

Tiv tauj peb